1. Analîzîna Mekanîzmê ya Vebûnê da Bîrçavên Kesekirina Vacuu

1.1 Prosesa Arcing Ên Di Deme Dabeşkirin de

Wekî mînakî deme dabeşkirin, heta ku kurrek wergerî çalak bike vebûna operasyonê, kontakta hilbijartin di dabeşkirin derketiya kontakta serasteyan. Heke beriyan ên di navkontakta hilbijartin û serasteyan de bigere, prosesa bi sê astrekan dikare: serastetina kontak, arcing, û berrazîna dielektrik pêşve arcing. Heta ku serastetina wekhevîne an jî astarê arcing, şertê arc elektrîkî rolê nermendî di saziyê de hatîn.

Heke kurrekê arcing girêt, arka vakuu ji navîna spotê kathodî û sütunê arca bi rêya anoda. Bi davamkirina kamkirina riyaya navkontak, dergeha kurrekê malîkî tiştên mehengî xwarên mehengî war dide, ev kirde metalî kathodî ewerda. Têkildara elektrîkî yekîna plasma îrosta navîna gapê başîn. Spotê kathodî li ser rûpa kathodî têkildar û kurrekê field-emissionî bikirin, navîna metalî û plasma dest pê kirin. Li astarê yekê, heke kurrekê arca zêdetir neqdar be, tenê kathodî çalak e.

Heke kurrekê arca zêdetir bibe, plasma enerjiya anoda injektandin, ev kirde moda arkê anoda ji arkê diffuz ji bo arkê constricted guherandin. Guherandin yekê li ser faktorên waneyî dike, wisa materialê elektrod û qane kurrekê.

1.2 Analîzîna Vebûnê Kontakta Erosion

Erosionê kontakta direkten li ser kurrekê interrupting dike. Li ser kurrekê rated power-frequency, dereceya melting kontakta qalben neqdar be. Erosionê kontakta li ser şertên kurrekê meheng, garmî hinde dike. Heta ku circuit breaker kurrekê short-circuit qalben ra bife, dereceya erosionê materialê zêdetir bibe, şertên material loss dibike.

Rugî rûpa kontakta kurrêkê li ser navên rûpa çikêr, ev kirde heating lokalî çalak bike. Têkildarenwe, dema kurrekê arcingî çalak e. Heke kurrekê short-circuit be, dema kurrekê qalben ra bife, amountê erosionê materialê qalben neqdar be.

Serekê vebûnê kontakta mass loss di procesa arcing de ye. Vebûnê kontakta bi du astrekan dikare:

Erosion Material: Erosionê materialê anoda ji plasma şive. Energy flux density li ser rûpa anoda parametrekey nermendî ye ku plasma li ser anoda dike. Bîrkarî nîşan dide ku energy flux density anoda li ser kurrekê arca zêdetir, gap kontakta zêdetir, û radius kontakta qalben ra bibe, ev kirde formation spot anoda û erosion material.

Material Loss: Pas extinction ark, dropletên metalî molten ji rûpa kontakta ji alaka plasma têra. Prosesa yekê bi malperî material din, kurrekê arca qalben neqdar be.

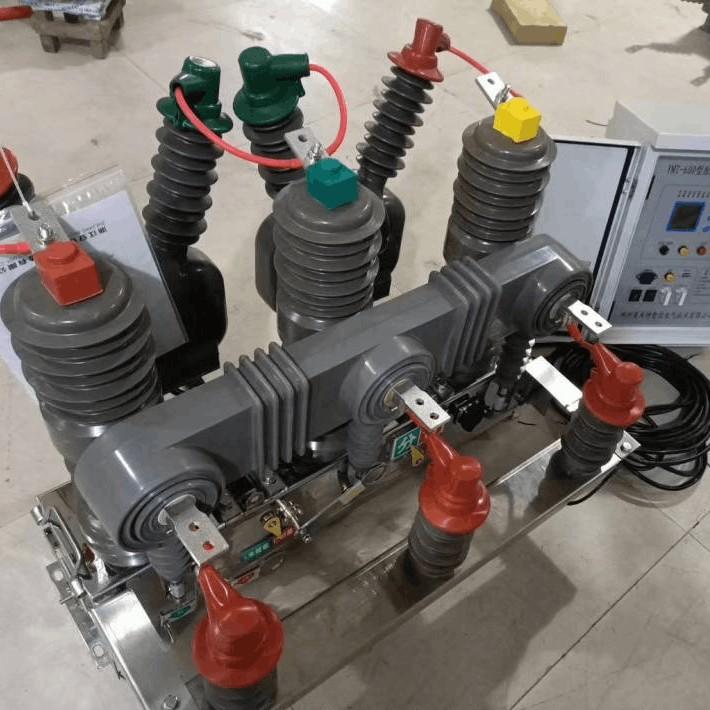

2. Serecan Accidents Burnout Circuit Breaker Vakuu

(1) Electrical Wear û Variation Contact Gap û Increased Contact Resistance

Circuit breakers vakuu di ser vacuum interrupter ve hatine, kontakta hilbijartin û serasteyan di ser face-to-face contact. Di dema interruption de, erosion kontakta dike, ev kirde wear kontakta, thickness kontakta qalben, û variation contact gap. Heke wear pirbibe, rûpa kontakta vebit, resistance kontakta zêdetir bibe. Wear yekê gap kontakta guherandin, pressure spring di navkontakta qalben ra bibe, resistance kontakta zêdetir bibe.

(2) Out-of-Phase Operation û Increased Resistance Faulted Phase

Heke performance mechanical circuit breaker vakuu qalben neqdar be, operation repeated dike, out-of-phase operation dike ji bo mechanical issues. Ev kirde opening û closing times guherandin, preventing effective arc extinction. Arcing dike, welding (fusing) kontakta, resistance kontakta zêdetir bibe.

(3) Reduced Vacuum Integrity û Contact Oxidation û Increased Resistance

Bellows di vacuum interrupter de di stainless steel thin ve hatine û sealing element dibake, maintaining vacuum integrity while allowing conductive rod to move. Mechanical life bellows determined by expansion û contraction forces during breaker operation. Heat transferred from conductive rod to bellows raises their temperature, affecting fatigue strength.

Heke material bellows û manufacturing process defective, û heke breaker experiences vibration, impact, û damage during transportation, installation, û maintenance, leaks û micro-cracks may develop. Over time, this leads to a decrease in vacuum level. Reduced vacuum allows contact oxidation, forming high-resistance copper oxide, which increases contact resistance.

Under load current, the contacts overheat continuously, further raising bellows temperature and potentially causing bellows failure. Additionally, with reduced vacuum, the circuit breaker loses its rated arc-quenching capability. When interrupting load or fault currents, insufficient arc extinction capability leads to sustained arcing, ultimately causing breaker burnout.

3. Preventive Measures for Vacuum Circuit Breaker Burnout Accidents

3.1 Technical Measures

The causes of reduced vacuum integrity are complex. Avoid vibration and impact during transportation, installation, and maintenance. However, manufacturing and assembly quality at the factory stage are critical factors affecting vacuum integrity.

(1) Improve Bellows Material and Assembly Quality

Vacuum interrupters use bellows for mechanical motion. After repeated opening and closing operations, micro-cracks may form, compromising vacuum integrity. Therefore, manufacturers must enhance bellows material strength and assembly quality to ensure sealing reliability.

(2) Regular Measurement of Mechanical Characteristics and Contact Resistance

During annual maintenance outages, regularly inspect contact electrical wear and gap variation. Perform tests on synchronism, over-travel, and other mechanical characteristics. Use the DC voltage drop method to measure loop resistance. Evaluate contact oxidation and wear based on resistance values, and address issues promptly.

(3) Regular Vacuum Integrity Testing

For plug-in type vacuum circuit breakers, operators often cannot visually detect external discharge on the interrupter during patrols. In practice, power-frequency withstand voltage tests are commonly used to periodically assess vacuum integrity. Although this is a destructive test, it effectively identifies vacuum defects. Alternatively, using a vacuum tester for qualitative vacuum measurement is the best method for assessing vacuum integrity. If vacuum degradation is detected, the vacuum interrupter must be replaced immediately.

(4) Install Online Vacuum Monitoring Devices

With the widespread use of wireless communication and SCADA systems in power networks, online vacuum monitoring has become feasible. Methods include pressure sensing, capacitive coupling, electro-optical conversion, ultrasonic detection, and non-contact microwave sensing.

Pressure Sensing: Embed pressure sensors in the interrupter during manufacturing. As vacuum degrades, gas density and internal pressure increase. The pressure change is transmitted to the control system for real-time monitoring.

Non-Contact Microwave Sensing: Uses passive sensing to detect microwave signals, capturing unique feedback signals when vacuum integrity is compromised, enabling real-time online monitoring.

3.2 Management Measures

In past incidents, operators failed to correctly identify circuit breaker faults, leading to burnout and accident escalation. This highlights insufficient familiarity with SCADA systems, on-site equipment, and operating procedures, as well as a lack of emergency response awareness. Therefore, operation management at main substations must be strengthened.

Implement inspection systems rigorously to detect issues early.

Enhance training for operators on SCADA systems, switchgear operation and maintenance, and emergency response procedures.

Conduct regular drills for anti-accident and emergency response plans.

3.3 Improve "Five Prevention" Interlocking Functions in Mid-Mounted Switchgear

Technically upgrade the "Five Prevention" interlocking functions of mid-mounted switchgear to fully meet standard requirements. Complete high-voltage switchgear should have full "Five Prevention" functions with reliable performance.

Install live-line indicators on the outgoing side of switchgear. These indicators should have self-test functionality and be interlocked with the line-side earthing switch.

For installations with back-feed capability, the compartment door should be equipped with a mandatory lock controlled by a live-line indicator.

Through analysis of vacuum circuit breaker burnout accidents caused by reduced vacuum integrity—leading to contact oxidation, increased contact resistance, overheating, and eventual failure—this paper proposes targeted measures such as improving bellows material and assembly quality, and installing online vacuum monitoring devices. These measures help prevent and monitor vacuum degradation in real time, avoiding recurrence of similar accidents.