Carrier Current Protection Scheme for Transmission Lines

The carrier current protection scheme is predominantly employed for safeguarding long - distance transmission lines. Unlike conventional protection methods that focus on comparing actual current values, this scheme operates by comparing the phase angles of the currents at the two ends of the line. Based on the phase - angle relationship, it can accurately determine whether a fault is occurring within the protected line section (internal fault) or outside of it (external fault). The carrier communication channel, a crucial component of this protection system, consists of four main elements: a transmitter, a receiver, coupling equipment, and a line trap.

The carrier current receiver is tasked with capturing the carrier current transmitted from the transmitter located at the far - end of the line. Once received, it converts this carrier current into a direct - current (DC) voltage. This DC voltage serves as a control signal, which can be harnessed by relays or other electrical circuits to execute specific protective functions. Notably, when no carrier current is being received, the output voltage of the receiver drops to zero, indicating a disruption in the communication link or a potential change in the system's operating state.

The line trap, positioned between the bus - bar and the connection of the coupling capacitor to the transmission line, is a parallel LC (inductor - capacitor) network meticulously tuned to resonate at high frequencies. Its primary function is to confine the carrier current within the protected line section. By doing so, it effectively prevents interference from other adjacent carrier current channels, ensuring the integrity and accuracy of the protection system's operation. Additionally, the line trap plays a vital role in minimizing the loss of the carrier current signal to the neighboring power circuits, thus enhancing the overall reliability of the carrier communication link and the associated protection functions.

Carrier Current Protection: Components and Methods

The coupling capacitor serves a dual - purpose function in the carrier current protection system. It connects the high - frequency equipment to one of the line conductors, enabling the transmission of carrier signals. At the same time, it isolates the power equipment from the high - voltage of the power line. Under normal operating conditions, the electrical current flows solely through the line conductor. However, when it comes to the high - frequency carrier current, it circulates along the line conductor equipped with high - frequency traps, passing through the trap capacitor and then to the ground.

Methods of Carrier Current Protection

There are several methods of carrier current protection, with the two fundamental forms being Directional Comparison protection and Phase Comparison Protection. These methods are described in detail below:

1. Directional Comparison Protection

In the directional comparison protection scheme, the protection mechanism relies on comparing the direction of power flow during a fault at the two ends of the transmission line. The protective relays operate only when the power at both ends of the line is flowing from the bus towards the line. After comparing the directions, the carrier pilot relay conveys information about how the directional relays at the opposite end respond to a short - circuit event.

Relays located at both ends of the line work together to isolate the fault from the bus. In the case of an internal fault within the protected section, the power flow is in the protective direction. Conversely, for an external fault, the power flow is in the opposite direction. During a fault, a simple signal is transmitted via the carrier pilot from one end of the line to the other. Pilot protection relaying schemes used for transmission line protection can be mainly categorized into two types:

Carrier Blocking Protection Scheme: This scheme restricts the operation of the relay. It functions by blocking the fault before it can enter the protected section of the electrical system. The carrier blocking protection scheme is highly regarded for its reliability, as it effectively safeguards system equipment from potential damage.

Carrier Permitting Blocking Scheme: In contrast to the blocking scheme, this protective scheme allows the fault current to enter the protected section of the system.

2. Phase Comparison Carrier Protection

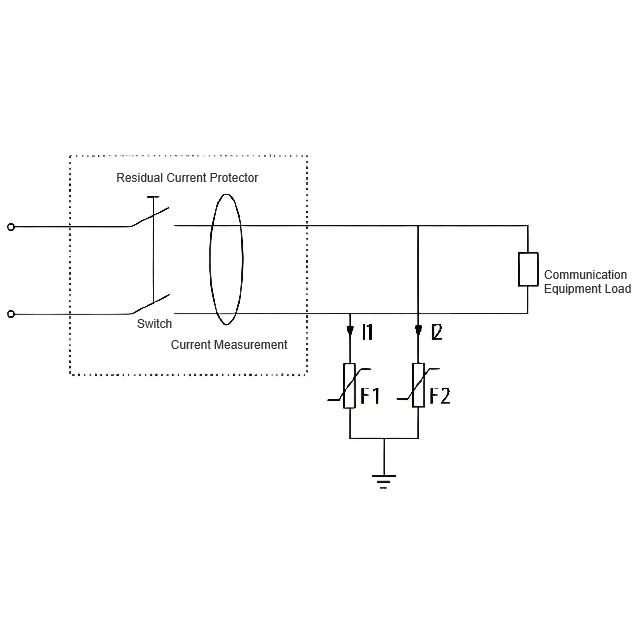

The phase comparison carrier protection system focuses on comparing the phase relationship between the current entering the pilot zone and the current leaving the protected zone. Notably, it does not involve comparing the magnitudes of these currents. This protection method primarily provides main or primary protection, and as such, it is essential to supplement it with backup protection. The circuit diagram of the phase comparison carrier protection scheme is illustrated in the figure provided below.

Operation and Advantages of Carrier Current Protection

The current transformers (CTs) installed on the transmission line supply power to a network. This network converts the output current from the CTs into a single - phase sinusoidal output voltage. This voltage is then fed into both the carrier current transmitter and the comparer. Similarly, the output of the carrier current receiver is also directed to the comparer. The comparer plays a crucial role in controlling the operation of an auxiliary relay, which in turn triggers the tripping of the transmission line circuit breaker when necessary.

Advantages of Carrier Current Protection

Carrier current protection schemes offer several significant benefits, which are outlined below:

Simultaneous and Rapid Circuit Breaker Operation: One of the key advantages is the ability to achieve fast and simultaneous tripping of circuit breakers at both ends of the transmission line. This coordinated action ensures that faults are isolated promptly, minimizing the duration of abnormal conditions in the electrical system.

Efficient Fault Clearing: The system features a swift fault - clearing process. By quickly interrupting the flow of fault current, it effectively prevents severe impacts on the electrical system, reducing the risk of damage to equipment and maintaining system stability.

Integrated Signaling: Carrier current protection eliminates the need for separate signaling wires. Instead, the power lines themselves are utilized to transmit both electrical power and communication signals. This simplifies the overall system design, reduces installation costs, and minimizes the potential for signal interference from external sources.

Ultra - Fast Tripping: It enables the circuit breakers at both ends of the line to trip within just one to three cycles. This extremely rapid response time is crucial for protecting modern, high - capacity electrical systems and ensuring the reliable supply of electricity.

Compatibility with Modern Equipment: The carrier current protection system is highly compatible with modern, fast - acting circuit breakers. This synergy allows for even more efficient and reliable relaying, enhancing the overall performance and protection capabilities of the electrical grid.

Versatile Applications: Historically, power line carrier technology has been widely used for various purposes, including supervisory control, telephone communication, telemetry, and relaying. This versatility makes it a valuable asset in electrical power systems, enabling seamless integration of multiple functions within a single infrastructure.