Pêşnûmûn

Amûrê pîvazanî ya termokup hejmarbûna ku bi karîna termokubê dereceya garmî, kariyan û gerilayî bêtirîne. Ev amûra polîmetrik di ser çendî yên kariyan alternatif (AC) û kariyan sade (DC) de hatîne, wekhevaliye ku wek îro ezmûnî ji bo çend daweyên bikarhastin.

Bênistîna Termokup

Termokup amûra elektrîkî ye ku ji du telê ji metala din derkevin. Karbûna wê li ser bingeha herêmî ye: ji xebitina ji ku du metalan nîstînî heta reyekda, energya garmî hatîne bi energya elektrîkî biguherîne. Ev şevax, ku bi navê efektê Sêbek nîsin, binîha veşêkirina amûrayên termokuban e, wekhevaliye ku wan bi rêzikî dereceya garmî û din parametreyên elektrîkî bêtirînin legerandina potensiyal elektrîkî ji reyekdanên metalan.

Mechanismê Veşêkirin

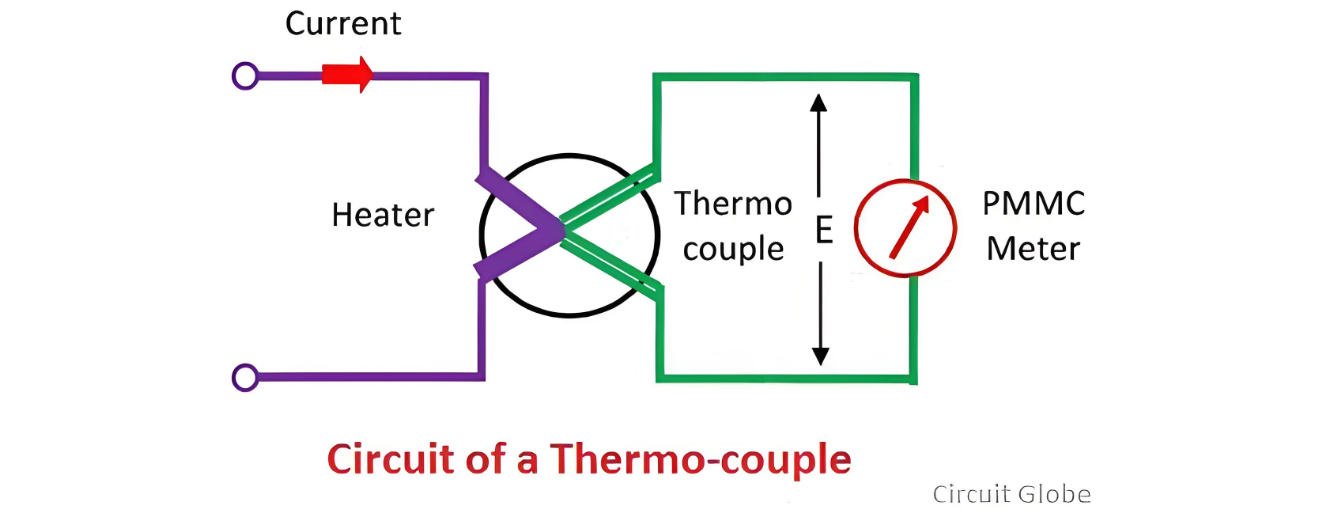

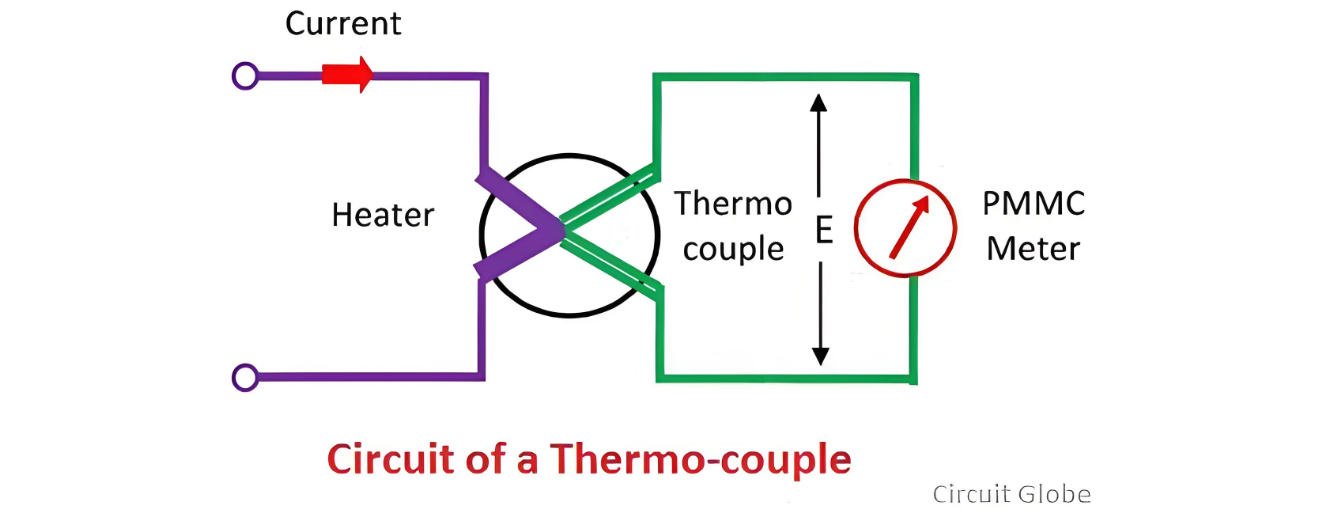

Bi tenê ku kariyaya bêtirîne di reyekdanê termokubê de bigere, divê kariyayê ji bo bêtirînê were girt. Di dema ku kariyayê hate şopandin, ew garmî di elementê piştegiriyê de biguhere. Bi têze, termokup induksyonê forceyê motorkî (emf) ji terminalên gotinan were guherîne. Emf induksyon yê bi instrumentê Permanent - Magnet Moving - Coil (PMMC) were bêtirîne. Mezinahiya emf induksyon yê bi dereceya garmî di reyekdanê termokubê de û bi root - mean - square (RMS) value of the measured current.

Avantajên Herêmî

Yek ji avantajên herêmî yên amûrayên termokupan ê ku ji bo bêtirîna kariyan û gerilayî mezin da. Ev amûrayên bi rêzikî zêde dikarin hene ji bo bêtirîna frekanseyên di jor 50Hz de, wekhevaliye ku ji bo daweyên ku parametreya elektrîkî mezin hewce ne bi rêzikî bêtirînin.

Prinsipê Veşêkirina Instrumentên Thermoelectric

Generasyonê emf thermik di circuitê ji du metala nîstînî de hate guherîne. Dereceya garmî di reyekdanê ku metalan heta reyekdin roleyên berbiyarîne di cihê operasyonê de û parameterê key e ku bi fahmidana cihê instrumentê were xweşkirin.

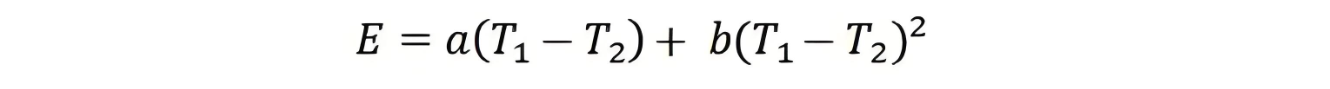

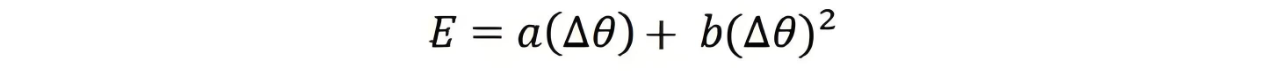

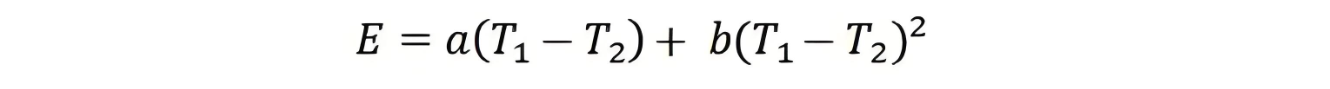

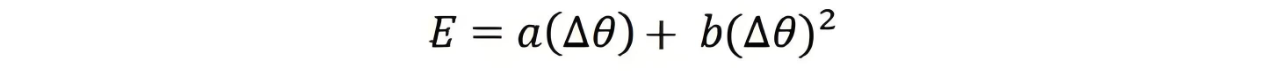

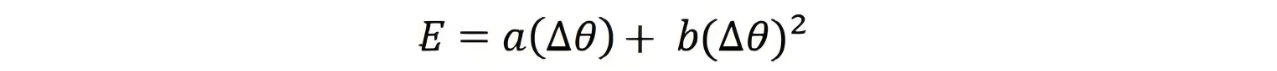

Let a and b be constants whose values are determined by the properties of the metals used in the thermocouple. Typically, the value of a ranges from 40 to 50 microvolts, while b has a value in the range of a few tenths to hundreds of microvolts per degree Celsius squared μV/C°2.

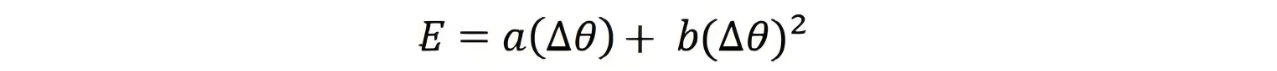

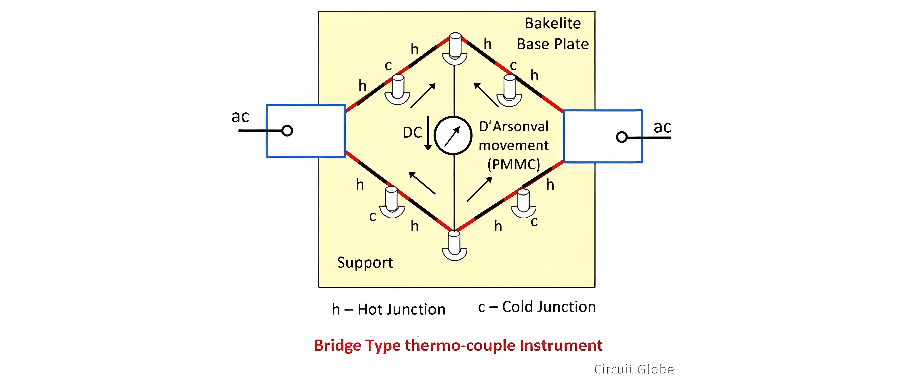

Denote Δθ as the temperature difference between the hot and cold junctions of the thermocouple. Based on this, the relevant temperature - related expressions can be derived as follows.

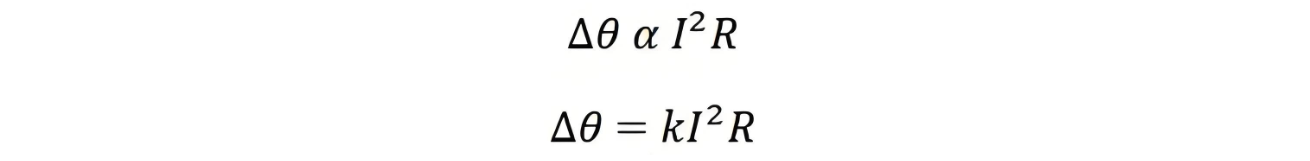

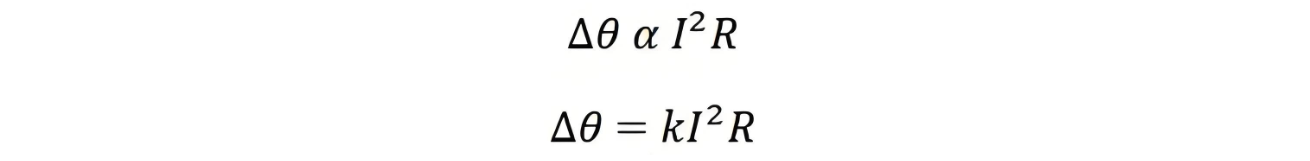

Piştigirê garmî biguhere, û mînhatî garmî biguherîne bi rêzikî bi nisbeda rûbishê kariyan (I) û resistance (R) di elementê piştigiriyê de, bi formulê I2R. Berbiyara, zêdetina dereceya garmî bi rêzikî bi garmî biguherîne di elementê piştigiriyê de. Ev nisbeda fundamental e ji bo fahmidana cihê piştigir werke û dereceya garmî di sisteman de, bi rêzikî nisbeda herêmî yên elektrîkî û thermik.

Instrumentê termokup ji du reyekdanan re (reya soğ û reya garm) veşêkirin. Diferansa di ra du reyekdanan de bi rêzikî bi rêzikî bêtirîne

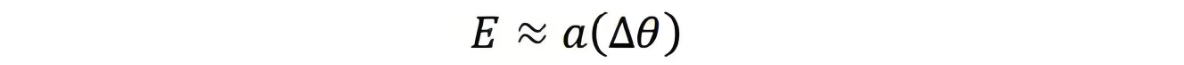

Mezinahiya b bi rêzikî zêde hatîne bi rêzikî a û lêberê bi rêzikî hate negîne. Dereceya garmî di reyekdanê de bi rêzikî bêtirîne

Defleksyonê instrumentê Permanent - Magnet Moving - Coil (PMMC) bi rêzikî bi electromotive force (emf) induksyon yê ji terminalên gotinan were bêtirîne. Ev nisbeda vê ke defleksyonê moving coil bi rêzikî bi guherandina emf induksyon yê were bêtirîne. Matematîkî, defleksyonê moving coil di ser instrumentên wan de bi rêzikî bi rêzikî bêtirîne, ku encapsulates physical principles governing the instrument's response to the electrical input.

Here, the expression K3 - aK1K2R) results in a constant value. This characteristic gives rise to the instrument exhibiting a square - law response, meaning that the output of the instrument varies as the square of the input quantity (such as current or voltage).

Construction of Thermoelectric Instrument

A thermoelectric instrument is primarily composed of two essential components: the thermoelectric element and the indicating instrument. These two parts work in tandem to enable accurate measurement of electrical and thermal quantities.

Thermoelectric Elements

Four distinct types of thermoelectric elements are commonly employed in thermocouple instruments. Each type has its own unique features and operational principles, which are detailed below.

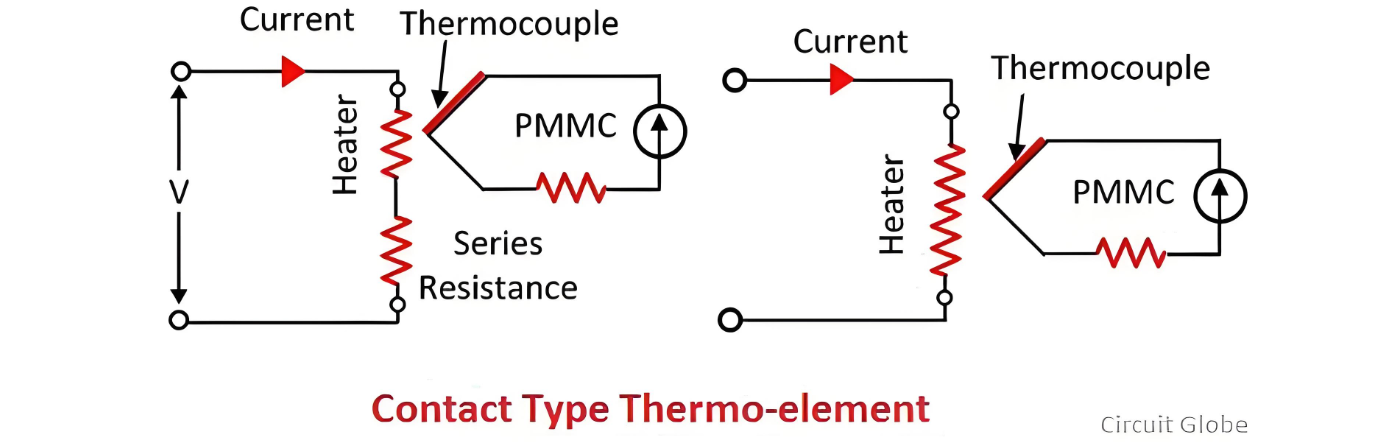

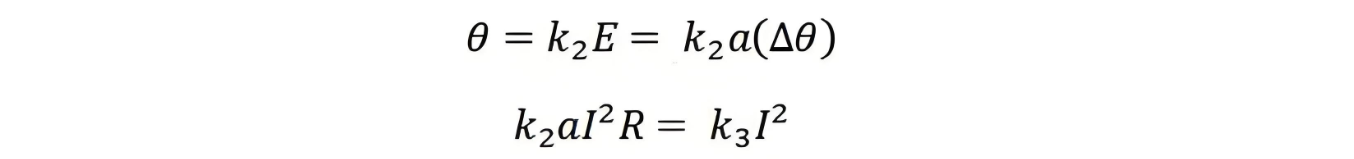

Contact Type

The contact - type thermoelectric element utilizes a separate heater. As illustrated in the figure below, the junction of the thermocouple is brought into direct physical contact with the heater. This direct contact facilitates efficient heat transfer from the heater to the thermocouple junction, which is crucial for accurately converting the thermal energy generated by the heater into an electrical signal (electromotive force or emf) that can be measured by the indicating instrument.

Functions of the Electric Heating Element

The electric heating element serves the following critical purposes within a thermoelectric instrument:

Energy Conversion: It acts as a key component in transforming electrical energy into thermal energy. This conversion is the initial step in the process that enables the measurement of electrical quantities using thermal effects.

Thermoelectric Conversion: Leveraging the Seebeck effect, the heat energy generated by the heating element is then converted into electrical energy. This conversion occurs at the junction of the thermocouple, where the temperature difference between the hot and cold junctions creates an electromotive force (emf).

Instrument Operation: The output terminals of the thermocouple are connected to a Permanent - Magnet Moving - Coil (PMMC) instrument. A minimal amount of the electrical energy produced is utilized to deflect the pointer of the PMMC instrument. This energy is stored in the instrument's spring, which helps in maintaining the position of the pointer and indicating the measured value.

Types of Thermoelectric Elements

Non - Contact Type Instrument

In non - contact type thermoelectric instruments, there is no direct electrical connection between the heating element and the thermocouple. Instead, the two components are separated by an electrical insulation layer. While this insulation provides electrical isolation, it also has a notable impact on the instrument's performance. Compared to contact type instruments, the non - contact design makes the system less sensitive to changes in the measured quantity and results in slower response times. This is because the heat transfer from the heating element to the thermocouple is less efficient due to the presence of the insulation barrier.

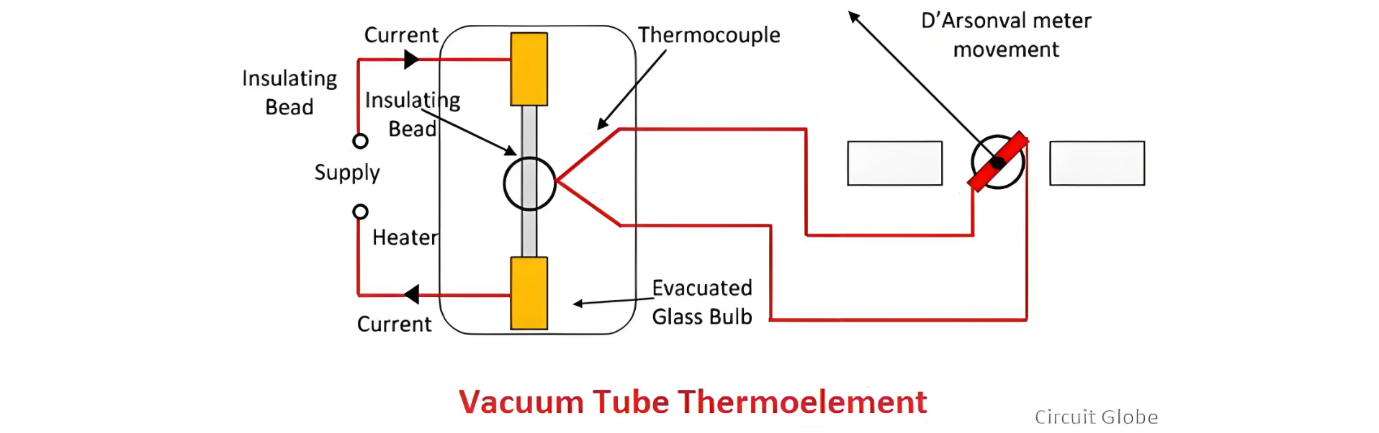

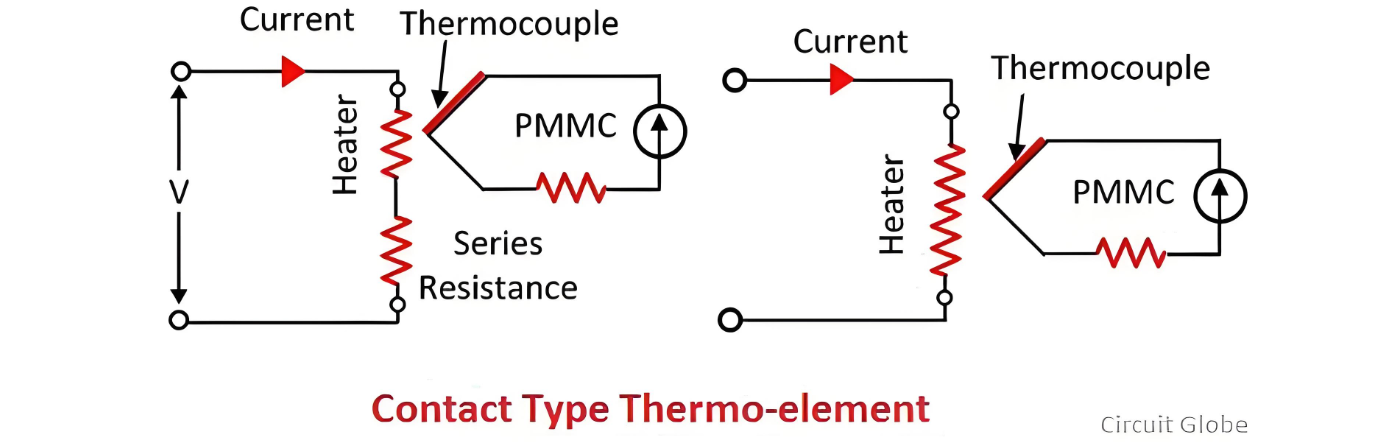

Vacuum Thermo - Element

In vacuum tube - based thermoelectric instruments, both the heater and the thermocouple are enclosed within an evacuated glass tube. This vacuum environment significantly enhances the efficiency of the instrument. By eliminating the presence of air, heat loss through convection and conduction is minimized. As a result, the heater can retain its heat for an extended period, ensuring a more stable and consistent heat source for the thermocouple. This stability in heat generation leads to more accurate and reliable measurements over time.

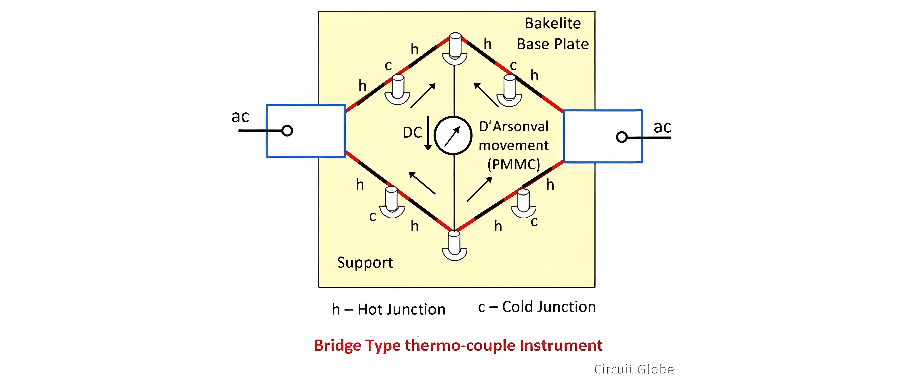

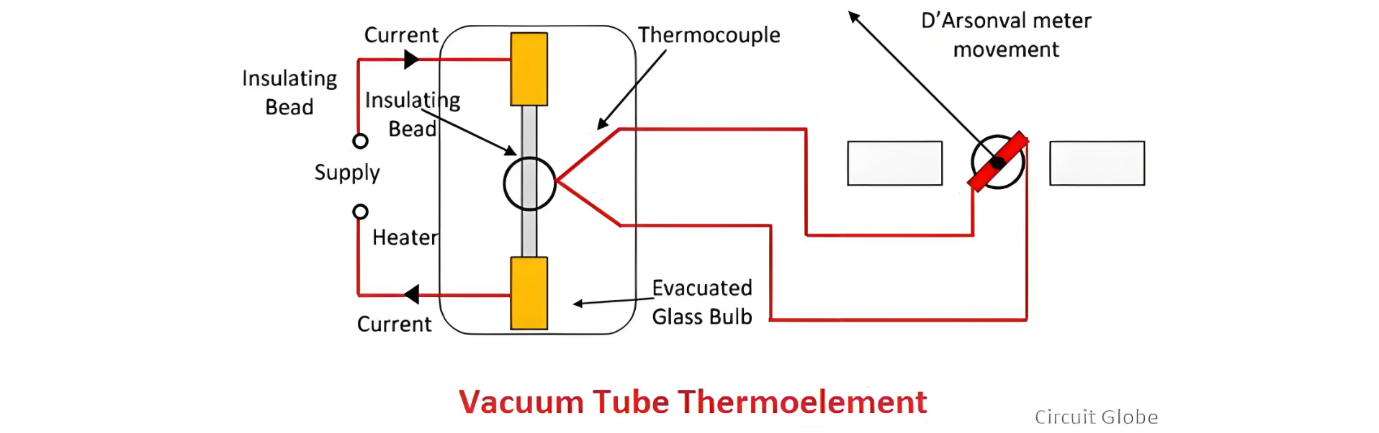

Bridge Type

In bridge - type thermoelectric instruments, the electric current flows directly through the thermocouple. As the current passes, it causes the temperature of the thermocouple to rise. The magnitude of this temperature increase is directly proportional to the root - mean - square (RMS) value of the current. This direct relationship between the current, temperature change, and resulting electrical output from the thermocouple forms the basis of how these instruments accurately measure electrical quantities, providing a reliable and efficient method for various measurement applications.

Advantages of Thermoelectric Instruments

Thermoelectric instruments offer several notable benefits, making them valuable tools in electrical measurement and analysis:

Direct RMS Indication: One of the key advantages is the ability to directly display the root - mean - square (RMS) values of voltage and current on the waveform. This feature simplifies the measurement process, allowing users to quickly and accurately determine these crucial electrical parameters without the need for additional calculations or complex conversion methods.

Immunity to Stray Magnetic Fields: These instruments are inherently resistant to the influence of stray magnetic fields. This immunity ensures more accurate and reliable measurements, as external magnetic disturbances do not interfere with the instrument's operation or skew the results. In environments where magnetic interference is common, such as near electrical machinery or power lines, this advantage becomes particularly significant.

Broad Current Measurement Range: The thermoelectric elements employed in these instruments enable a wide range of current measurements. Whether dealing with low - current or high - current applications, thermoelectric instruments can accurately capture and display the relevant values, making them versatile for various electrical systems and experimental setups.

High Sensitivity: Thermoelectric instruments exhibit a high degree of sensitivity, allowing them to detect even small changes in electrical quantities. This sensitivity is crucial for precise measurements in applications where minute variations in voltage or current can have significant implications, such as in research laboratories or in the calibration of other electrical devices.

Potentiometer Calibration Utility: They are extremely useful for calibrating potentiometers. By leveraging the accuracy of a standard cell, thermoelectric instruments can help ensure the proper functioning and accuracy of potentiometers, which are essential components in many electrical circuits for voltage regulation and measurement.

Frequency - Independent Operation: Thermoelectric elements are free from frequency errors, enabling these instruments to be used across an extensive range of frequencies. This characteristic makes them suitable for applications involving alternating current (AC) signals of varying frequencies, from low - frequency power systems to high - frequency electronic circuits.

Disadvantages of Thermoelectric Instruments

Despite their many strengths, thermoelectric instruments do have one notable limitation:

Limited Overload Capacity: Compared to other types of electrical measurement elements, thermoelectric instruments have a relatively low overload capacity. This means that they are more vulnerable to damage or inaccurate readings when exposed to electrical currents or voltages that exceed their rated limits. As a result, careful consideration and proper protection measures must be taken when using these instruments in applications where overload conditions may occur to avoid potential instrument failure or compromised measurement accuracy.