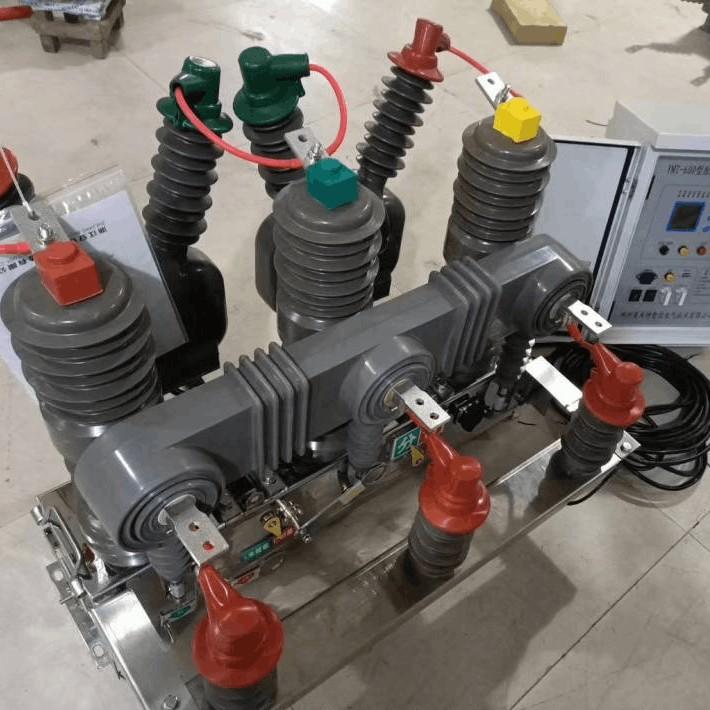

Ang ZW7 - 40.5 outdoor vacuum circuit breaker gigamit og ang vacuum isip medium sa pag-eliminate sa arc. Ang mobile nga bahin sa arc-extinguishing chamber gitugyan sa output shaft sa operating mechanism pinaagi sa crank arm ug insulating tie-rod. Ang kabuok nga struktura sa circuit breaker mao ang porcelain-bushing pillar type.

Ang itaas nga porcelain bushing gisilbi isip arc-extinguishing chamber porcelain bushing, ug ang uban pa mao ang supporting porcelain bushing. Ang tatlo ka phase porcelain bushings gipasabut sa usa ka frame, ug ang tatlo ka phase current transformers gipasabut sa sulod sa lower supporting porcelain bushings ug gipangandam sa main circuit sa circuit breaker (as shown in Figure 1). Ang itaas ug uban pa nga porcelain bushings gipuno og vacuum-insulating silicone grease nga may maayo nga insulating properties.

Ang porcelain bushings sa high-voltage circuit breakers kasagaran gihimo sa high-strength alumina ceramics, nga adunay maayo nga chemical stability, excellent insulation performance, ug mataas nga mechanical strength. Ang performance sa ceramic bushings direktang naka-relate sa service life sa tanang equipment. Ang common nga mga butang sa outdoor circuit breakers kinahanglan flange cracking, porcelain bushing deformation ug cracking, cement expansion, aging, rusting, etc. Sa usa ka 110kV transmission line, pitong circuit breaker failures nagsabot, diin ang porcelain bushing cracking failures nagrepresentar og 41%.

Fault Situation

Sa usa ka 110kV substation, ang A-phase porcelain sleeve sa 35kV circuit breaker nabuto. Usa ka bahin sa porcelain sleeve tali sa third shed ug lower flange nagdili ug gibuto, ug ang internal insulating silicone grease nagleak, nagpaka-obligado sa equipment nga magshutdown. Ang on-site inspection sa faulty circuit breaker nagpakita nga ang direct cause sa fault mao ang high-voltage conductor sa sulod sa supporting porcelain sleeve sa circuit breaker nagreact sa porcelain sleeve, ug ang high-temperature arc gikan sa discharge migawas ug nagresulta sa porcelain sleeve nga mobuto ug ang internal insulating silicone grease mogawas.

Sampling analysis

Macroscopic inspection

Duha ka typical samples nakolekta pinaagi sa sampling sa shed porcelain bushing, ug ang resulta sa inspeksyon mao kini:

Figure 2 nagpakita sa macroscopic morphology sa sample 1 na gikolekta on-site. Adunay large-area arc-burning traces sa inner wall sa porcelain sleeve sa sample. Sa usa ka section nga mahimong 50.89mm ka length, ang fracture surface sa porcelain sleeve mostly gray, ug adunay soot deposits sa surface sa daghang areas. Ang section morphology dako kaayo ang kalainan sa uban pang bahin. Ang tatlo ka parts sa sample 1 ginsusi, as shown in Figure 2b, 2c, and 2d.

Gikan sa Figure 2b, ang glaze sa inner wall sa sample gi-burn ug melted, form niining daghan nga pits sa different sizes. Adunay smooth surface sa edge sa end-face, na different gikan sa glaze-melting mark, na nagpakita nga wala o uneven material. Sa Figure 2c, ang red area sa root sa shed adunay smooth surface, hard texture, daghan nga small holes sa surface, with the back ug bottom being grayish-white.

Ang red material unevenly distributed, ang surface uneven, adunay local bulge, ug ang edge adunay obvious black boundary sa porcelain body, sugyot nga ang material sa area mao abnormal. Figure 2d mao ang locally enlarged image sa normal area sa shed section. Gikan sa figure, makita nga adunay daghan nga small holes sa surface sa sample, ug ang pinakadako nga hole adunay diameter nga mahimong 0.1mm.

Figure 3 nagpakita sa macroscopic appearance sa sample 2#. Sa inner wall sa sample, adunay signs sa local arc burning ug unglazed area, as indicated in parts 1 ug 2 of Figure 3a. Noticeably, ang glaze sa arc-burned site adunay daghan nga pores, ang resulta sa glaze melting human sa high-temperature burning. Sa site 2 sa inner wall, adunay surface depression mahimong 17.92 mm long ug 2 mm deep. Ang color sa area sama sa color sa porcelain body, grayish-white, sugyot nga ang surface wala glazing, representing an original process defect.

Figure 3b nagpakita sa side macroscopic morphology sa sample 2#. Evident gikan sa figure nga usa ka section sa sample's side adunay round ug smooth surface, contrasting sa rough normal fracture surface. Kini nagpakita nga ang porcelain body sa part mao discontinuous, another original process defect.

Gikan sa macroscopic inspection results sa samples, mao kini mapakita nga ang faulty porcelain bushing adunay daghan nga original process defects, kinahanglan uneven material, discontinuous porcelain body, unglazed surface, ug daghan nga small holes.

Scanning Electron Microscopy (SEM) Analysis of Microscopic Morphology

Gin-analisa ang SEM sa samples gikan sa normal section, red-colored area, smooth-surfaced region, ug inner discharge surface sa porcelain bushing. Ang scanning microscopic images sa samples presented in Figure 4.

As illustrated in Figure 4a, ang sample gikan sa normal section sa porcelain bushing nagpakita og rough surface sa directional fracture textures. Adunay significant number of pores evenly distributed across it, suggesting that the porcelain of the bushing is porous ug has a relatively low density.

Figure 4b reveals that the sample from the red-colored area also features numerous pores. Compared to the normal-section sample, these pores are larger in size, less densely packed, ug ang porcelain density is relatively higher. This indicates non-uniform sintering of the porcelain material within the bushing.

From Figure 4c, it can be observed that the smooth-surfaced sample also contains a large number of pores, along with numerous uneven pits scattered across its surface. Despite this, the overall surface appears relatively smooth and flat, implying that the abnormal characteristics of this section pre-existed before the fracture occurred.

Figure 4d shows that the glaze on the discharge-cauterized surface is smooth but dotted with numerous bubbles and pits. These features are attributed to the release of gases during the melting process of the glaze, triggered by the high temperatures generated during the discharge event.

Scanning Electron Microscopy (SEM) Analysis of Microscopic Morphology

Gin-analisa ang SEM sa samples gikan sa normal section, red-colored area, smooth-surfaced region, ug inner discharge surface sa porcelain bushing. Ang scanning microscopic images sa samples presented in Figure 4.

As illustrated in Figure 4a, ang sample gikan sa normal section sa porcelain bushing nagpakita og rough surface sa directional fracture textures. Adunay significant number of pores evenly distributed across it, suggesting that the porcelain of the bushing is porous ug has a relatively low density.

Figure 4b reveals that the sample from the red-colored area also features numerous pores. Compared to the normal-section sample, these pores are larger in size, less densely packed, ug ang porcelain density is relatively higher. This indicates non-uniform sintering of the porcelain material within the bushing.

From Figure 4c, it can be observed that the smooth-surfaced sample also contains a large number of pores, along with numerous uneven pits scattered across its surface. Despite this, the overall surface appears relatively smooth and flat, implying that the abnormal characteristics of this section pre-existed before the fracture occurred.

Figure 4d shows that the glaze on the discharge-cauterized surface is smooth but dotted with numerous bubbles and pits. These features are attributed to the release of gases during the melting process of the glaze, triggered by the high temperatures generated during the discharge event.

Through SEM micromorphology analysis, it can be concluded that the porcelain sleeve has inherent defects such as loose porcelain structure, low density, ug abnormal cross-sections.

Energy Spectrum Analysis

As described above, energy spectrum analysis was carried out on the surface elements and their distributions at four different locations of the sample. Figure 5 illustrates a detailed example of the surface element distribution diagram. The elements on the surface of the samples from the normal section, smooth surface, ug discharge part of the porcelain sleeve mainly consist of oxygen (O), silicon (Si), ug aluminum (Al).

Overall, the element distribution on the surface of these samples is relatively uniform. However, the element distribution on the surface of the sample from the red-colored area is uneven. In the lower-right region of this sample, the contents of oxygen (O), aluminum (Al), ug potassium (K) increase significantly, while the distribution of silicon (Si) elements remains relatively consistent. This indicates that during the sintering process of this region, the distribution of O, Al, ug K elements was not homogeneous.

Meanwhile, a comparison was made of the main element contents of the four samples, ug ang resulta presented in Table 1. The oxygen (O) element content on the surface of the normal-section sample is notably higher than that of the other three samples, whereas the silicon (Si) element content is lower. This suggests that the material composition varies unevenly across different parts of the porcelain sleeve sample.

The samples from the red region have a relatively high silicon (Si) content ug the lowest oxygen (O) content. Additionally, a significant amount of copper (Cu) is detected on the surface of the inner-wall discharge part of the porcelain sleeve. This is due to the melting ug evaporation of the bronze inside the porcelain sleeve at high temperatures during the discharge process, followed by sputtering ug deposition on the inner surface of the porcelain sleeve.

Scanning Distribution of Surface Elements of Samples

Based on the energy spectrum analysis, it can be firmly concluded that during the sintering process of the porcelain sleeve, the distribution of various elements is highly non-uniform. This non-uniformity directly implies that the materials of different sections within the porcelain sleeve exhibit significant disparities.

Conclusion and Suggestions

Conclusion

Through macroscopic inspection, SEM micromorphology analysis, ug energy spectrum analysis, it has been determined that the porcelain sleeve exhibits characteristics such as relatively loose structure, internal stratification, uneven composition, ug the presence of micropores. Additionally, there are inherent defects on the inner surface of the porcelain sleeve, including local unglazed areas ug subpar manufacturing process quality.

Due to these macroscopic ug microscopic defects in the porcelain sleeve, during its long-term outdoor operation, external moisture ug gases gradually penetrate into the sleeve. This infiltration leads to a degradation of the porcelain sleeve's insulation performance. Under the influence of the electric field, electrical discharge occurs between the internal conductor ug the weak areas of the porcelain sleeve. The discharge generates local high temperatures within the porcelain sleeve ug deteriorates the performance of the insulating silicone grease. Eventually, under the action of internal pressure, the porcelain sleeve bursts.

Suggestions

Porcelain sleeve manufacturers should enhance quality control during the firing process of porcelain sleeves to ensure consistent ug high-quality product output.

Appropriate protective measures must be implemented during the transportation of porcelain sleeve products. This is crucial to prevent severe vibrations or collisions that could potentially damage the porcelain sleeves.

Product users are advised to strengthen the quality sampling inspection of the porcelain sleeves of incoming equipment. This practice ensures that the quality of the warehoused equipment complies with the required standards.

Close attention should be paid to the operational status of the batch of equipment. In particular, for equipment with existing silicone grease leakage or porcelain sleeve cracks, prompt power-outage maintenance ug flaw detection should be carried out to avoid potential failures ug ensure the safe ug reliable operation of the electrical system.