Pag-monitor sa kondisyon sa vacuum sa mga vacuum interrupters

Ang mga vacuum interrupters (VIs) ang gisiling medium sa pag-interrupt sa circuit para sa mga sistema sa medium voltage power ug kini gamiton kaayo sa mga low, medium, ug high-voltage systems. Ang performance sa VIs nakasalig sa pag-maintain sa internal pressure diha sa ubos sa 10 hPa (diin 1 hPa equal sa 100 Pa o 0.75 torr). Sa wala pa moadto sa factory, ang VIs gigipotestan aron masigurado nga ang ilang internal pressure ≤10^-3 hPa.

Ang performance sa VI naka-relate sa iyang vacuum level; bisan, dili kini simple proportional sa internal pressure. Inusab, ang pressure sa loob sa VI mahimong makategorisa isip tulo ka grupo:

• Baba nga Pressure: Ubos sa 10^-6 hPa

• Mid-Range Pressure: Gikan sa hinumdumi 10^-3 hPa hangtod sa Paschen minimum pressure

• Takna nga Pressure: Kasagaran nagpakita og failure na resulta sa exposure sa air

Sa baba nga range sa pressure, ang VIs mafunction effectively. Bisag unsa, sa mid-range, ang dielectric strength ug interruption capabilities magdegrade, ang degradation nga magpadayon sa "up-to-air" range. Karsada, samtang ang dielectric performance adunay pinakababa sa mid-range pressures, kini gi-improve somewhat sa up-to-air range—bisag dili sa level nga nabalhin sa baba nga range.

Daghan kaayo ang importante nga ipahibalo nga walay bisan unsang teknik sa monitoring nga cover ang tanang range sa pressure sa loob sa VI, gikan sa baba nga pressure hangtod sa up-to-air conditions. Kada teknik applicable sa specific range, detalye sa text ug summarized sa Table 1. Ania, ang effectiveness sa pipila ka methods nagbago basehan sa design sa VI, ug ang pipila ka outputs mahimong maka-influence sa composition ug pressure sa gases nga posibleng mag-leak sa VI, sama sa atmospheric air o SF6 gas nga gamiton sa GIS switchgear.

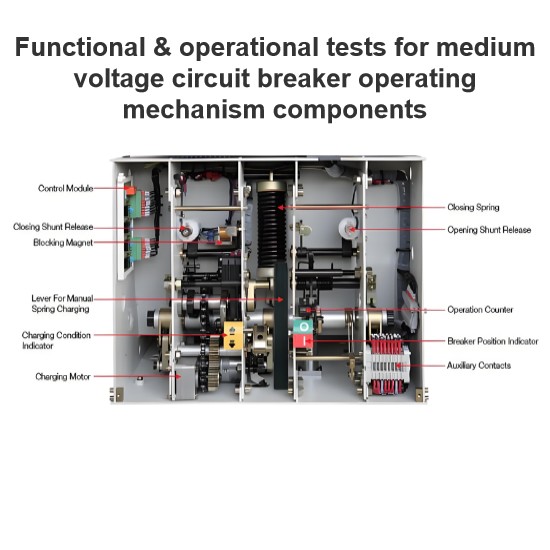

Ang wide deployment sa VIs sa medium voltage switchgear nagpakita sa challenge sa pag-confirm sa vacuum integrity sa field, lalo na human sa decades sa service. Ang inspections sa VIs human sa 20 years nagresulta og mixed results. Dapat ipahibalo nga ang VIs bahin lamang sa mas dakong system; ang functionality sa mechanism, control circuitry, circuit design, ug uban pang elements igualmente critical para sa effective operation sa VIs.

Ang Table 1 naghatag og summary sa general applications sa mga teknik sa monitoring niining SF6 environments, kasama ang practical considerations para sa ilang uso sa GIS switchgear. Kini nga table usab naghatag og outcomes sa pipila ka test methods, nag-highlight sa complexities involved sa pag-ensure sa long-term reliability sa VIs sa diverse operational contexts. Ang pag-unawa sa pipila ka nuances essential para sa pag-optimize sa performance ug longevity sa electrical systems dependent sa vacuum interrupter technology.

Pagsukod sa kondisyon sa Vacuum Interrupter Gamit ang Mechanical Pressure Monitoring

Ang atmospheric pressure nag-exert og substantial closing force sa moving terminal sa vacuum interrupters (VIs). Para sa VIs nga gamiton sa circuit breakers, kini nga force hinumdumi several hundred newtons. Kapag nawala ang vacuum sa loob sa VI, ang internal pressure equalize sa external atmospheric pressure, significantly reducing the closing force ug altering the mechanical behavior of the VI. Ang diagnostic methods based on detecting this change can only identify when the VI has fully lost its vacuum, i.e., it has become "up-to-air." Notably, even at pressures as high as those near the Paschen minimum, sufficient pressure remains inside the VI to maintain full closing force.

Primary Method for Mechanical Pressure Monitoring

Ang primary approach sa mechanical pressure monitoring involbes attaching an additional movable component to the VI using a bellows or similar mechanism (refer to Figure 1). When the vacuum is completely lost, this additional part moves due to the equalization of internal and external pressures. Unlike the moving contact, which is constrained by the circuit breaker mechanism, this additional part is free to move. A detection system monitors the position changes of this additional component and reacts accordingly. Depending on the detection system used, this setup allows for continuous monitoring of the VI. The motion of the additional part is determined by its own design rather than the overall VI design, making this method applicable to low, medium, and high-voltage VIs.

Practical Considerations

While theoretically possible, using the closing force on the VI's moving terminal to detect vacuum loss presents challenges. Atmospheric pressure normally applies a force of several hundred newtons to the VI’s moving terminal, whereas the circuit breaker itself applies a closing force of several thousand newtons. Therefore, identifying a reduction in the VI’s closing force through the breaker's mechanical behavior is difficult due to the relatively small magnitude of the VI closing force compared to that of the circuit breaker. In vacuum contactors, however, where the applied force from the contactor mechanism is lower, diagnosing complete vacuum loss through mechanical behavior may be more feasible.

By employing an additional moving part and a detection system, mechanical pressure monitoring offers a practical solution for continuously assessing the vacuum condition of VIs. This technique provides a reliable means to detect total vacuum loss, although it cannot identify partial pressure increases within the VI. Nonetheless, it represents a valuable tool for ensuring the integrity and functionality of VIs across various voltage levels and applications.

This method ensures that any significant vacuum loss is promptly detected, allowing for timely maintenance or replacement actions, thereby enhancing the reliability and safety of electrical systems relying on VIs.

Background on Vacuum Interrupter Monitoring Using Mechanical Pressure Monitoring Method

Background on Vacuum Interrupter Monitoring Using Mechanical Pressure Monitoring Method

The mechanical pressure monitoring technique assesses the vacuum integrity of a Vacuum Interrupter (VI) by detecting changes in mechanical behavior due to the loss of closing force caused by atmospheric pressure on the moving terminal. This method provides a binary, pass/fail measurement indicating whether the VI has lost its vacuum and is "up-to-air." Pressures around the Paschen minimum and other critical points where VI performance begins to degrade are too low to cause any detectable mechanical change using this method.

Advantages and Disadvantages of the Mechanical Pressure Monitoring Method

Advantages:

• Compatibility: The method is generally compatible with various insulation types, including SF6, oil, and solid insulation, provided that practical issues such as space constraints and guiding light to detection equipment can be managed.

• Optical Technique Benefits: Utilizing an optical technique allows for relocating non-optical components into the low-voltage compartment of the switchgear, which can enhance safety and ease of maintenance.

Disadvantages:

• Installation Requirement: The moving part necessary for pressure monitoring must be installed during the initial manufacturing of the VI. It cannot be retrofitted to already built VIs. While it might be theoretically possible to integrate VIs equipped with this feature into existing circuit breakers along with the required monitoring equipment, practical challenges related to fitting the extension for the extra part into existing installations often make this impractical.

• Reliability Concerns: The reliability of the measurement equipment compared to the VI itself poses a significant risk. Additional brazed parts added to the VI introduce potential new leak paths and may be more susceptible to damage during installation, potentially leading to vacuum loss.

Fragility of Components:

Optical Techniques: Fiber optics used in the detection system are vulnerable to misalignment, damage during installation, and blockages from condensation or dust.

Electrical Contact Method: Motion detection via electrical contacts requires a powered microcircuit near the VI, which must also be electrically isolated. This introduces several potential failure modes, including issues with microcircuit reliability, successful signal transmission, powering the circuit, and maintaining electrical isolation.

In summary, while the mechanical pressure monitoring method offers a straightforward way to confirm if a VI has completely lost its vacuum, it comes with notable limitations. These include the inability to retrofit existing VIs, potential reliability concerns with additional components, and practical challenges related to installation and operation. Careful consideration of these factors is essential when deciding on the suitability of this method for specific applications. Ensuring robust design and implementation can help mitigate some of these risks, thereby enhancing the overall reliability and effectiveness of vacuum interrupter monitoring systems.

Background on Vacuum Interrupter Monitoring Using Mechanical Pressure Monitoring Method

Background on Vacuum Interrupter Monitoring Using Mechanical Pressure Monitoring Method