Bayyana na Amfani da Kula da Tsarin Zafi a Cikin Vacuum Interrupters

Vacuum interrupters (VIs) suna yi waɗannan mulki na amfani da su a cikin tushen kuli mai tsari don tattalin arziki, kuma suna amfani da su da yawa a tushen kuli mai tsari da ke kadan, da ke nuna, da ke mata. Ingantaccen VIs ya kunshi da inganta matsayinta a kan zafi masu kyau daga 10 hPa (don haka 1 hPa ce 100 Pa ko 0.75 torr). Idan an fitar da VIs daga makaranta, ana bayyarta cewa zafin ta gine ≤10^-3 hPa.

Ingantaccen VI ya shiga da matsayinta zafin; amma ba shi ne daidai da zafi. Ba haka, zafi a cikin VI yana iya girma da sauran abubuwa uku:

• Zafi Masu Kyau: Daga 10^-6 hPa zuwa haske

• Zafi Masu Tsakiya: Daga fashe 10^-3 hPa zuwa zafin Paschen minimum

• Zafi Masu Yawan: Wannan ya nuna fa'ilu da ya jawo jirgin zafi

A cikin zafi masu kyau, VIs sun yi aiki da kyau. Amma a cikin zafi masu tsakiya, matsayin kuli da kuma yadda ake koyar da aiki sun ci gaba, wannan ci gaban ya haɓaka zuwa "up-to-air" range. Abin da ake gudanar, idan matsayin kuli ya shiga da matsayi a cikin zafi masu tsakiya, yana da shirya wajen ci gaba a cikin up-to-air range—amman ba sai dai da matsayin da aka sani a cikin zafi masu kyau.

Yana da muhimmanci a tabbatar da cewa babu wata na alama daga cikin abubuwan da aka magana a kan, take kula da matsayin tsari zuwa up-to-air conditions. Kowane wata na iya amfani a cikin fagen rike, an bayyarta a cikin rubutu kuma an kawo shi a Table 1. Da ma'a wannan, darajar da addinin kalmomin suna yi da yawa a kan design ta VI, da kuma abubuwan da za su iya canza da zafi da kuma gas da suka lafiya cikin VI, misali jirgin zafi ko SF6 gas da ake amfani a GIS switchgear.

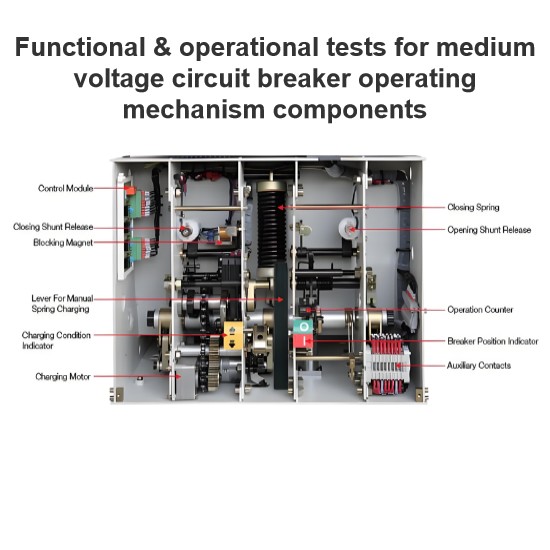

Amfani da VIs da yawa a cikin tushen kuli mai tsari na nuna maimaita na tabbatar da matsayin zafi a kan taron, yawanci a kan shekaru dubu da kadan da suke yi aiki. Bayyartar VIs bayan shekaru biyar da kadan suke yi aiki suna baya abubuwan da suka fi faru. Yana da muhimmanci a tabbatar da cewa VIs suna zama batu daya a cikin tsohon system; yadda aiki ta mechanism, control circuitry, tattalin arziki, da sauransu suna da muhimmanci wajen yi aiki da kyau a cikin VIs.

Table 1 ta bayyarta abubuwan da suke amfani a cikin environment na SF6, tare da abubuwan da suke yi da yawa a kan amfani da GIS switchgear. Wannan table tana kawo shi abubuwan da suka samu shi a kan kalmomin, na nuna maimaita na kula da matsayin tsari a kan VIs a wuraren abubuwan da suke yi aiki. Fahimtar wannan abubuwan yana da muhimmanci wajen inganta matsayin aiki da tsari na electrical systems da suke amfani da vacuum interrupter technology.

Kula da Matsayin Tsari na Vacuum Interrupters Ta Hanyar Mechanical Pressure Monitoring

Jirgin zafi na zamani ya ba closing force mai yawa a cikin terminal mai yawa da VI. Don VIs da ake amfani a cikin circuit breakers, wannan force tana da kusan newtons. Idan zafin ta VI ya kama da kusa, zafi na ta gine ya haɗa da jirgin zafi na zamani, wanda ya ci gaba closing force da ya haɗa da mechanical behavior ta VI. Kalmomin da suke yi da cewa suke samun wannan ci gaban ya ba su iya samun da VI ya kama da zafin, ya'ni ya zama "up-to-air." Amsa, hatta a zafi masu yawan, akwai zafi masu kyau a cikin VI wanda yake da shi da yin closing force mai yawa.

Fagen Rike na Mechanical Pressure Monitoring

Fagen rike na mechanical pressure monitoring ya haɗa da fadada movable component da ake kara da VI ta hanyar bellows ko wasu abubuwan da suke da kyau (tazama Figure 1). Idan zafin ta VI ya kama da kusa, wannan additional part ya haɗa da kasa saboda haɗin zafi na ta gine da jirgin zafi na zamani. Yanzu, ba kamar moving contact, wanda ake haɗa da circuit breaker mechanism, wannan additional part ya fi kasa da yin aiki. Detection system ta haɗa da kasa changes in position ta wannan additional component da ya reji masu yawa. Tare da detection system da ake amfani, wannan setup ya ba su iya yi continuous monitoring ta VI. Motion ta additional part tana da shi da design ta ta hanyar, ba da design ta VI, wanda yana ba wannan method da yin amfani a cikin low, medium, and high-voltage VIs.

Abubuwan da Suke Yi da Yawa

Idan ake amfani da closing force ta moving terminal ta VI don samun kama da zafin, akwai abubuwan da suke yi da yawa. Jirgin zafi na zamani tana ba force mai kusan newtons a cikin terminal mai yawa ta VI, amma circuit breaker tana ba closing force mai kusan thousands newtons. Saboda haka, samun kama da closing force ta VI ta hanyar mechanical behavior ta circuit breaker tana da abubuwan da suke yi da yawa saboda yawan closing force ta VI tana da shi da closing force ta circuit breaker. Amma a cikin vacuum contactors, inda applied force ta contactor mechanism tana da yawa, samun kama da zafin ta hanyar mechanical behavior tana da yawa.

Ta hanyar additional moving part da kuma detection system, mechanical pressure monitoring tana ba su iya yi practical solution don continuous assessment ta condition ta zafin a cikin VIs. Wannan technique tana ba su iya samun kama da zafin mai yawa, amma ba tana iya samun partial pressure increases a cikin VI. Amma, yana zama valuable tool don tabbatar da integrity da kuma functionality ta VIs across various voltage levels and applications.

Wannan method tana tabbatar da cewa abin da yake da shi da kama da zafin tana samun da yawa, wanda yana ba su iya yi maintenance ko replacement actions da yawa, wanda yana inganta reliability da kuma safety ta electrical systems da suke amfani da VIs.

Background on Vacuum Interrupter Monitoring Using Mechanical Pressure Monitoring Method

Background on Vacuum Interrupter Monitoring Using Mechanical Pressure Monitoring Method

Mechanical pressure monitoring technique tana kula da condition ta zafin ta Vacuum Interrupter (VI) ta hanyar samun changes in mechanical behavior saboda kama da closing force caused by atmospheric pressure on the moving terminal. Wannan method tana ba su iya binary, pass/fail measurement indicating whether the VI has lost its vacuum and is "up-to-air." Pressures around the Paschen minimum and other critical points where VI performance begins to degrade are too low to cause any detectable mechanical change using this method.

Advantages and Disadvantages of the Mechanical Pressure Monitoring Method

Advantages:

• Compatibility: The method is generally compatible with various insulation types, including SF6, oil, and solid insulation, provided that practical issues such as space constraints and guiding light to detection equipment can be managed.

• Optical Technique Benefits: Utilizing an optical technique allows for relocating non-optical components into the low-voltage compartment of the switchgear, which can enhance safety and ease of maintenance.

Disadvantages:

• Installation Requirement: The moving part necessary for pressure monitoring must be installed during the initial manufacturing of the VI. It cannot be retrofitted to already built VIs. While it might be theoretically possible to integrate VIs equipped with this feature into existing circuit breakers along with the required monitoring equipment, practical challenges related to fitting the extension for the extra part into existing installations often make this impractical.

• Reliability Concerns: The reliability of the measurement equipment compared to the VI itself poses a significant risk. Additional brazed parts added to the VI introduce potential new leak paths and may be more susceptible to damage during installation, potentially leading to vacuum loss.

Fragility of Components:

Optical Techniques: Fiber optics used in the detection system are vulnerable to misalignment, damage during installation, and blockages from condensation or dust.

Electrical Contact Method: Motion detection via electrical contacts requires a powered microcircuit near the VI, which must also be electrically isolated. This introduces several potential failure modes, including issues with microcircuit reliability, successful signal transmission, powering the circuit, and maintaining electrical isolation.

In summary, while the mechanical pressure monitoring method offers a straightforward way to confirm if a VI has completely lost its vacuum, it comes with notable limitations. These include the inability to retrofit existing VIs, potential reliability concerns with additional components, and practical challenges related to installation and operation. Careful consideration of these factors is essential when deciding on the suitability of this method for specific applications. Ensuring robust design and implementation can help mitigate some of these risks, thereby enhancing the overall reliability and effectiveness of vacuum interrupter monitoring systems.

Background on Vacuum Interrupter Monitoring Using Mechanical Pressure Monitoring Method

Background on Vacuum Interrupter Monitoring Using Mechanical Pressure Monitoring Method