Pamalas sa Vacuum Interrupters ug Bellows

Bisag unsa ang teknolohiya ug ang pagkamausab sa global warming, ang vacuum circuit breakers nagsilbi isip importante nga bahin sa electrical engineering domain.

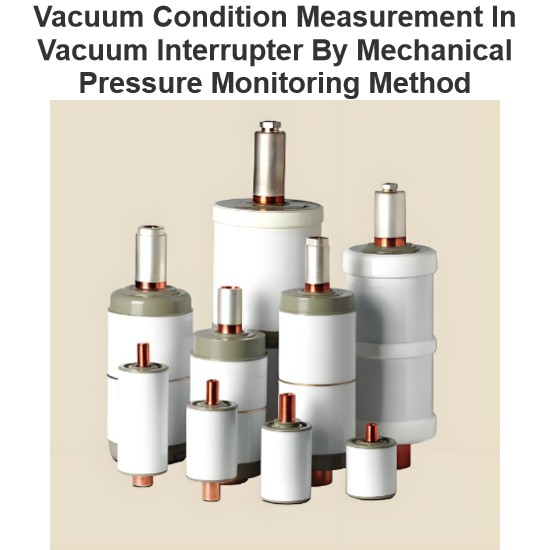

Ang mga future power grids naghatag og mas stringent nga demand sa switching performance sa mga circuit breakers, sama sa mas taas nga switching speeds ug mahimong pag-operate sa dili pa maayo. Sa medium-voltage circuit breakers, ang vacuum interrupters (VIs) nagsilbi isip napulupundok nga gipili. Kini tungod kay ang paggamit sa vacuum isip interrupting medium naghatag og wala makatuyonan nga bulagta sa karon nga aplikasyon. Ang vacuum interrupter adunay core component sa vacuum circuit breaker, ug ang bellows nagsilbi isip importanteng bahin sa vacuum interrupters.

Ang metal bellows gihimo aron mapreserbar ang ultra-high vacuum seal samtang gitugotan ang translational movement sa moving electrical contact sa interrupter chamber. Apan, ang mechanical lifespan sa vacuum interrupter kasagaran limitado sa giingong vacuum bellows. Sa konteksto sa future circuit breakers, ang pagtumong sa mas taas nga switching speeds magresulta sa mas taas nga dynamic impact-type loads. Kini makapuyo sa bellows oscillations nga may mas taas nga amplitude, resulta niini ang significant reduction sa lifespan sa bellows. Giya sa expected increase sa frequency sa switching operations sa future power grids, ang simulation sa vacuum bellows naging indispensable aron optimisar ang design ug pinaagi niini mapataas ang mechanical lifespan sa vacuum interrupters.

Ang Role sa Bellows sa Vacuum Interrupters

Ang bellows, kasagaran gihimo gikan sa thin stainless-steel sheets, gihimo aron matuman ang opening ug closing sa contacts samtang mapreserbar ang vacuum environment sa interrupter.

Ang fatigue resistance sa bellows mao ang key factor nga magdeterminar sa mechanical life sa vacuum interrupter. Ang bawg contact opening ug closing operation mograbi sa bellows ngadto sa stress, lalo na ang convolutions nga nahimutang labi ka close sa ends. Bisan pa ang direct mechanical stress gikan sa operational movement, ang bellows usab mosensyahan sa post-operation oscillations human sa contact motion magstop. Kini nagpadayon sa wear and tear sa bellows, nag-accelerate sa degradation sa panahon.

Figure 1 nagpakita og specific type sa bellows para sa vacuum interrupters gihimo sa Sigma-Netics company.

Fig 1: Vacuum Interrupter Bellows by Sigma - Netics compan

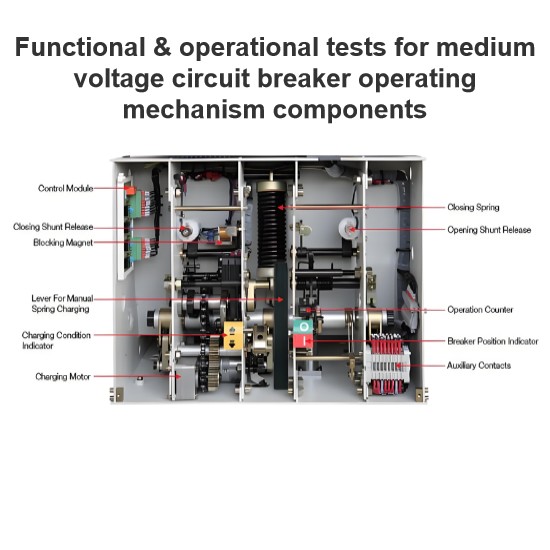

Ang mechanical life sa vacuum interrupters nagsilbi isip significantly influenced sa several critical contact motion parameters:

Steady-state contact stroke o gap: Kini magdeterminar sa distance sa contacts separate sa panahon sa operation, nag-influence sa electrical insulation ug arc-extinguishing capabilities.

Opening ug closing speed: Mas taas nga speeds makapadayon sa switching performance apan usab nag-impose og mas taas nga dynamic loads sa components, kasagaran ang bellows.

Motion damping sa end sa opening ug closing stroke: Adequate damping importante aron minompyo ang vibrations ug reduce ang mechanical stress sa bellows ug uban pang parts.

Overshoot ug rebound sa opening: Kini makapuyo sa additional wear and tear sa contacts ug bellows, potentially shortening the overall lifespan.

Mounting resilience: Ang way sa vacuum interrupter mounted maghatag og effect sa distribution sa forces sa panahon sa operation, influencing the mechanical life of the bellows.

Contact bouncing sa closing: Excessive contact bouncing makapuyo sa arcing ug increased stress sa bellows, degrading its performance over time.

Ang bellows nagsilbi isip dual-role sa vacuum interrupters. Sila enable ang movement sa moving contact samtang mapreserbar ang vacuum-tight seal. Gihimo gikan sa stainless steel, typically with a thickness of approximately 150 µm, sila gihimo aron matubag sa harsh operating conditions sa interrupter. Tulo ka types sa bellows nagsilbi sa vacuum interrupter designs:

Seamless hydroformed bellows: Kini gihimo without visible seams, potentially offering enhanced integrity ug performance.

Seam-welded hydroformed bellows: Gihimo sa welding seams after hydroforming, balancing cost ug performance requirements.

Bellows made from edge-welded, thin stainless-steel washers: Gihimo sa welding thin washers together, providing a cost-effective solution for certain applications.

Comprehensive details regarding bellows design ug performance makita sa EJMA Standards.

Ang usa ka end sa bellows securely fixed sa brazing it to the end plate sa vacuum interrupter, while the other end brazed to the moving terminal ug moves in tandem with it as the contacts open ug close. Sa vacuum interrupter, ang bellows subjected sa impulsive motion during contact operations. Ang opening speed sa moving contact can rapidly increase from 0 m/s to as high as 2 m/s in less than 100 µs. Sa end sa contact stroke, whether opening or closing, ang moving end sa bellows comes to an abrupt stop

Ang frequency sa open-close operations varies depending sa duty cycle. Sa some cases, they can occur numerous times, while in others, they are rare. The motion imparted sa bellows far from uniform, ug common for the bellows to oscillate multiple times during a single opening or closing operation. For those interested sa analyzing this bellows motion, a general analytical approach developed aron determine the dynamic stresses experienced by the bellows under impulsive motion.

Most vacuum interrupter manufacturers source their bellows from well-established bellows manufacturers ug collaborate with them aron achieve the desired bellows lifespan. This typically accomplished by incorporating the bellows into a practical vacuum interrupter ug conducting mechanical life tests on a statistically significant number of vacuum interrupter samples. A specified mechanical life can then be assigned to the vacuum interrupter with that bellows using Weibull analysis. Usually, the mechanical life limit of a vacuum interrupter determined by the number of operations the bellows can endure before fatigue failure occurs.

When mechanically testing a vacuum interrupter, it is crucial to subject the bellows to the same operating parameters it will encounter in a switching device. These parameters include the total travel (operating gap plus over-travel), maximum opening speed, maximum closing speed, ug the effects of acceleration ug deceleration. Testing the bellows within the vacuum interrupter ensures that it undergoes all the manufacturing steps that the finished device will experience. For instance, it should be exposed to all the heating ug cooling cycles required for vacuum interrupter manufacturing. These processes will inevitably anneal the metal of the bellows, altering its granular microstructure ug, consequently, its performance characteristics.

The mechanical life of a specific bellows depends not only on the above-mentioned operating parameters but also on its own physical attributes. These include the type of stainless steel used, its length, diameter, thickness, the number of convolutions, ug its ability to dampen motion once the contact stops moving. It is feasible to design bellows that can reliably perform the normal 30,000 operations required for most vacuum circuit breakers ug vacuum reclosers, ug even exceed 10^6 operations for vacuum contactors. However, despite vacuum interrupter manufacturers' efforts to design their products to meet the specified mechanical life of various switching devices, most vacuum interrupters do not reach their stated mechanical life when deployed in the field.For more insights into the failure reasons of Vacuum Interrupters (VIs), please refer to the relevant article.

The vacuum interrupter designer must take precautions to prevent the user from twisting the bellows when installing the vacuum interrupter into a mechanism. A twisted bellows can have its mechanical life severely reduced, potentially to less than 1% of its designed lifespan. The torque that can be applied to the thin-walled bellows in a vacuum interrupter before permanent twisting is relatively low, approximately 8.5–11.5 Nm. To avoid bellows twisting, the designer should insert an anti-twisting bushing into it. This bushing can be locked in place by attaching it to the end plate of the interrupter. The inner surface of the bushing is shaped or features a keyway to prevent any rotation of the moving copper terminal attached to the bellows (as shown in Figure 2). The bushing material can be metal or a plastic such as Nylatron. When using plastic materials like Nylatron ug Valox, caution is necessary. These materials can only be used in applications where the maximum permissible temperature they will experience is limited. For example, for Nylatron, the temperature at which its tensional strength is reduced to 50% after 100,000 hours is approximately 125°C (it can withstand higher temperatures for short periods without deforming due to its glass fiber content), ug for Valox DR48, it is around 140°C. There are also more expensive, higher-temperature plastics available, such as “Ultem 2310 R.”

Fig 2: Examples of Anti-twist Bushings for Bellow Protection

The material used for these anti-twist bushings has a maximum permissible temperature of approximately 180°C. It can withstand short-term exposure (around 1 hour) to temperatures exceeding this limit without significant deformation.

For vacuum interrupters operating at higher circuit-breaker voltages, a longer contact stroke is necessary. For instance, at 72.5 kV, a stroke of roughly 40 mm is required. To accommodate this extended stroke, the bellows must be proportionally lengthened. However, very long bellows do not open ug close in a uniform manner. Instead, they tend to squirm during movement. As a result, the inner convolutions of the bellows may rub against the copper (Cu) terminal. This friction can substantially reduce the bellows' lifespan.

To address this issue, specialized bellows with internal pads have been developed. These pads slide along the Cu terminals, minimizing wear ug tear. An example of such a bellows design is illustrated in Figure 3.