Index

Modus Operandi Machinae Synchronae Usura Chopper

Ulterioris Progressus Machinae Synchronae Usura Chopper

Conclusio Machinae Synchronae Usura Chopper

Praecipua Disciplina:

Definitio Controli Excitationis: Definitur ut administratio excitationis campi DC in machina synchrona ad eius performantiam regendam.

Modus Operandi: Modus operandi machinae synchronae usura chopper involvit incrementum tensionis et eius controllem per signala PWM ad excitationem desideratam obtinendi.

Advantagia Chopper: Usura chopper pro controlo excitationis offert altam efficientiam, magnitudinem compactam, controllem lenem et responsionem celerem.

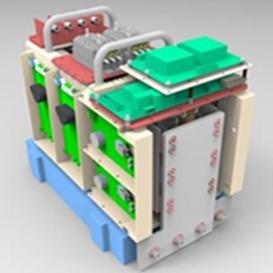

Componentes in Circuito Chopper: Principales componentes includunt MOSFET, signala modulandi latitudinis pulsus, rectificator, capacitor, inductor, et dispositiva protectionis sicut MOV et fusibile.

Futura Incrementa: Futura progressus possunt includere controllem circuli clausi pro oneribus variabilibus et componentes precisionis ad performantiam meliorandam et effectus temperaturarum reducendum.

Machina synchrona est versatilis machina electrica in variis campis, sicut generatio potestatis, servatio velocitatis constantis, et correctio factoris potentiae. Factor potentiae controlletur per gestionem excitationis campi DC. Haec thesi focus ponitur super quam efficaciter nos possumus controllare excitationem campi machinae synchronae.

Methodi DC excitationis traditionales obviant difficultatibus refrigerationis et maintenance propter anulus lubricos, pincernas, et commutatores, praesertim cum alternator ratings crescunt. Systemata moderna excitationis conantur minuere hos problemata per minimizationem numeri contactuum glissantium et pincernarum.

Hoc trend duxit ad developmentum excitationis staticae usura chopper. Systemata moderna utuntur dispositivis commutationis semiconductores sicut diode, thyristors et transistors. In electronica potentiae, quantitas magna energiae electricae processatur, converteres AC/DC sunt dispositiva typica maxime.

Potentia range typically ab decenas ad centenas wattorum. In industria, applicatio communis est drive variabilis velocitatis pro controllo velocitatis motor inductionis. Systemata conversionis potentiae classificantur per suos input et output types potentiae.

Tractatur de apparatu rotatorio et statico pro generatione, transmissione, utilisatione quantitatum vastarum potentiae electricae. Converter DC-DC est circuitus electronicus qui convertit fontem currentis directi ab uno tensione ad alium. Advantages of power electronic converters are as below-

Alta efficientia propter parvas perdas in dispositivis semiconductores potentiae.

Alta fidelitas systematis converteris electronicorum potentiae.

Longa vita et minus maintenance propter absentiam partium mobiles.

Flexibilitas in operatione.

Celeris responsio dynamica comparata ad systema converteris electromechanicalis.

Sunt etiam aliquot inconvenientia significativa converterum electronicorum potentiae sicut sequens-

Circuiti in systemate electronicorum potentiae habent tendentiam generandi harmonicas in systemate supply tamquam in circuito oneris.

AC ad DC et DC ad AC converter operantur sub basso input factor potentiae sub certis conditionibus operationis.

Regeneration potentiae difficilis est in systemate converteris electronicorum potentiae.

In hoc projecto, media tensio trans campum machinae synchronae controlletur usura chopper boost. Chopper boost est DC ad DC converter qui providet maiorem controlled output voltage ex fixa input DC voltage.

MOSFET est dispositivum semiconductore electronicum potentiae quod est switch totaliter controlatus (switch cuius turn on et turn off ambo possunt controlari). MOSFET usatur ut dispositivum commutationis in hoc circuitu chopper boost. Terminal gate MOSFET drivetur per signalum modulandum latitudinis pulsus (PWM). Quod generatur usura microcontroller. Supply voltage chopper captatur a rectificatore diode bridge per conversionem single phase AC/DC.

Hoc schema controlis excitationis campi est valde efficiente et magnitudine compacta, propter involvementem circuiti electronicorum potentiae. In multis applicationibus industrialibus, sicut controlis potestatis reactivae, factor potentiae improvement of linea transmissionis oportet mutare excitationem campi.

Hoc drive capitur a fixed DC source et convertitur in variabilem DC voltage. Systemata chopper offerunt controllem lenem, altam efficientiam, celerem responsionem et facilitatem regenerationis. Fundamentalis chopper potest considerari ut DC equivalent AC transformeris cum se comportant modo identico. Propter unum stage conversionis, haec sunt efficientiores.

Modus Operandi Machinae Synchronae Usura Chopper

Ut intelligamus details plani projecti consideremus hunc diagramma block:

Ex diagrammate supra possumus dicere quod pro input 230V full wave rectifier output voltage est 146 (Approx.) tensio campi machinae est 180V itaque oportet step up tensio per chopper boost. Nunc adjustata tensio DC alitur ad campum machinae synchronae. Output voltage chopper variari potest mutando duty cycle ut sic faciamus generator pulsu adjustable pulse width, et hoc fieri potest auxilio microcontroller.

In microcontroller comparando signalum random sequence cum constanti magnitudine possumus generare signalum pulsu sed ut vitemus effectum loadingi est consilium uti isolationem electricam ut hoc faciamus usamus opto coupler. A capacitor usatur in circuitu chopper ut removat ripple ex output voltage. Simulatum est quod inductor qui usatur in circuitu chopper debet esse capax 2-3 A currentis durante periodum short circuit. Praeter desideratam output voltage, debemus etiam designare circuitum ut sustineat omne conditum fault.

Pro overvoltage protection, usabimus metal oxide varistors (MOV) cujus resistance dependet a tensione.

Pro overcurrent protection, possumus uti first acting current limiting Fuse.

Ut melioremus qualitatem waveform possumus uti filter circuit basic L or LC filter at output of bridge rectifier. Diode qui usatur debet habere minus reverse recovery time hic possumus uti fast recovery diode.

Valores componentum circuiti qui usati sunt

Input DC Voltage = 100V

Pulse voltage = 10V, Duty = 40%

Chopping frequency = 10 KHz

R = 225 ohm (As calculated from the machine rating)

L = 10mH

C = 1pF

Data obtained from the output

Output voltage: 174 V (Average)

Load current: 0.775 A (Average)

Source current: 0.977 A

Ulterioris Progressus Machinae Synchronae Usura Chopper

Adhuc multum spatii pro futuro developmento quod augmentaret systema et augeret eius valorem commerciale.

Controllo circuli clausi

Application areas where the user deals with variable load, needs a closed loop control scheme to maintain constant excitation. Reference voltage and actual output voltage will be compared first and an error signal is generated. This error signal will decide the duty cycle of the chopper.

Reduction in temperature effect

Use of precision capacitor, switching diode can definitely improve the performance, but they will aid to the cost of the project.

Conclusion of Synchronous Machine Using Chopper

In our project, we designed and implemented a low-cost and user-friendly excitation controller using Chopper. The target users of the system are industries requiring smooth, efficient and small controller which gives a wide range of voltage variation. This type of project is really useful in the industrial fields of developing countries like India, where energy crisis is a great concern.

We have learned much through the project. We got the lesson of team work, co-ordination, leadership while going through various phases of development of the project. We were challenged by the complexity of the technologies needed to build the system. This helped us to co-relate and apply the theoretical knowledge we obtained in engineering course.

None of us had experience with electronic control of motor before the project. We needed to learn different concepts and techniques quickly and apply them in the system. The project also provided a chance for us to accumulate experience in pulse signal generation and power MOSFET control area. This project experience has greatly enriched our knowledge and sharpened our technical skills.