Pahayag

Ang brushless DC motor drive gitakda isip usa ka self-controlled variable frequency drive nga gamiton ang sinusoidal Permanent Magnet Alternating Current (PMAC) motor. Kini nga klase sa drive naghatag og daghang mahimong mga abilidad. Bisan praktikal na walay pangangamtuoran, kini maya-maya nga adunay pag-extend sa lifespan, nagpadali kini og reliable nga pagpipili alang sa daghang aplikasyon. Sa wala pa, adunay kini ka low rotational inertia, minimal friction, ug operasyon sa low-frequency characteristics. Masulti pa, adunay kini ka minimal radio frequency interference ug noise, sigurado kini nga smooth ug quiet nga operasyon. Apan dili kini walay drawback; ang primary limitations mao ang relatyibong mataas nga gasto ug low starting torque.

Aplikasyon

Ang brushless DC motor drives makita sa wide range sa industriya ug devices. Sa consumer electronics, ginamit kini sa record players, tape drives para sa recorders, ug spindle drives sa computer hard disks. Ginamit usab kini isip low-power drives sa computer peripheral instruments ug control systems. Wala pa sa consumer electronics, ang ilang aplikasyon naka-extend sa aerospace industry diin ang reliability ug low-noise operation kay crucial. Sa biomedical field, ang ilang precision ug clean operation nagbutang kini nga suitable para sa daghang medical devices. Sa wala pa, kasagaran kini gamiton aron mobo-ang cooling fans, naghatag og efficient ug quiet ventilation sa daghang sistema.

Motor Structure

Ang figure sa ubos nagpakita sa cross-section sa usa ka three-phase, two-pole trapezoidal PMAC motor, nga usa ka key component sa brushless DC motor drive. Ang motor adunay permanent magnet rotor nga may wide pole arc, nga nakatubok sa iyang efficient nga operasyon. Ang stator equipped ngadto sa three-pole windings, bawgon displaced sa 120 degrees gikan sa uban. Kini nga specific winding configuration nag-siguro sa balanced electrical operasyon ug smooth torque production. Bawgon phase winding spans 60 degrees sa duha nga bahin, optimizing ang magnetic field interaction sa loob sa motor ug enabling precise control sa iyang speed ug performance.

Ang voltages induced sa tulo ka phases sa motor depicted sa figure sa ubos. Ang generation sa usa ka trapezoidal waveform makapadayon sa specific interaction sa pagitan sa rotor ug stator. Kon ang rotor molihok sa counter-clockwise direction, samtang ang initial 120-degree rotation gikan sa reference position, tanang top conductors sa phase A mag-interact sa south pole sa magnetic field, samtang tanang bottom conductors sa phase A engage sa north pole.

Kini nga consistent magnetic coupling sa kini nga angular range mogihatag og relatively stable induced voltage, nakatubok sa flat top portion sa trapezoidal waveform. Sa sunod nga ang rotor molihok, ang changing magnetic field orientations mogihatag sa induced voltage nga motransisyon, ultimately forming the characteristic trapezoidal shape nga essential para sa proper operation ug control sa brushless DC motor drive.

Sa panahon sa 120-degree rotation sa rotor, ang voltage induced sa phase A remain relatively constant. Sa wala pa ang rotation exceeds 120 degrees, pipila ka top conductors sa phase A magsugyot sa north pole, samtang pipila pa mag-interact sa south pole. Pipila ka bottom conductors usab mag-interact sa parehas nga way. Resulta, sa sunod nga 60-degree rotation, ang voltage induced sa phase A linearly reverses. Kini nga pattern sa voltage change mirrored sa phases B ug C usab, creating a coordinated electrical behavior essential para sa motor's operation.

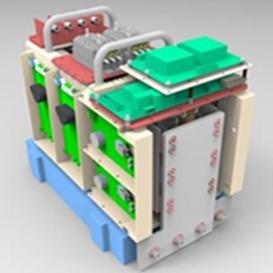

Ang brushless DC motor drive system, as illustrated in the figure below, consists of a voltage-source inverter paired with a trapezoidal PMAC motor. The stator windings of the motor are configured in a star connection. The figure also depicts the characteristic phase-voltage waveform of the trapezoidal PMAC motor, which reflects the unique voltage-induction dynamics described above. This waveform is a key feature that enables the efficient control and operation of the brushless DC motor drive, facilitating smooth torque production and precise speed regulation.

The stator windings of the brushless DC motor are supplied with current pulses. Each pulse has a duration of 120 electrical degrees and is precisely positioned within the region where the induced voltage remains constant and reaches its maximum value. Crucially, the polarity of these current pulses aligns with that of the induced voltage, ensuring a harmonious interaction between the electrical inputs and the magnetic field generated by the motor.

The air-gap flux within the motor is maintained at a steady level, and the magnitude of the induced voltage is directly proportional to the rotational speed of the rotor. This relationship is fundamental to the operation of the motor, as it allows for accurate control of the motor's performance based on the speed-dependent induced voltage, enabling efficient power transfer and smooth operation across various operating conditions.

During each 60-degree interval of operation, current flows into one phase of the motor's stator winding and exits from another. This alternating current flow pattern is a key characteristic of the brushless DC motor's operation. As a result, the power supplied to the motor within each of these 60-degree intervals can be expressed by the following formula, which takes into account the interaction between the voltage and current within the winding phases.

The torque developed by the motor

The torque waveform of the brushless DC motor drive is illustrated in the figure below. The magnitude of the torque generated by the motor is directly proportional to the current flowing through the DC power links. This relationship is fundamental to understanding the motor's dynamic behavior and performance characteristics.

Regenerative braking in this drive system is achieved by reversing the phase current. When the phase current is reversed, the direction of the current source Id also changes accordingly. This reversal initiates a power flow that starts from the motor, proceeds through the inverter, and ultimately returns to the DC source. During this process, the motor acts as a generator, converting the mechanical energy from the load into electrical energy, which is then fed back into the power supply. This not only helps in decelerating the motor but also allows for the recovery and reuse of energy, enhancing the overall efficiency of the system.

When the rotational speed of the drive system is reversed, the polarity of the induced voltages within the motor also flips. This change in voltage polarity triggers the regenerative braking operation, enabling the drive to convert the mechanical energy of the moving load into electrical energy that can be fed back into the power supply.

Conversely, reversing the direction of the current flowing through the motor's windings initiates the motoring operation, propelling the motor in the desired direction. The current waveforms corresponding to these distinct operating modes—regenerative braking and motoring—are clearly depicted in the figure below, providing a visual representation of the electrical behavior of the drive system under different conditions.

Types of Brushless DC Motor Drive

The brushless DC motor drive can be primarily categorized into two distinct types: the low-cost brushless DC motor drive and the single-phase brushless DC motor drive. Each type has its own unique characteristics and operational principles, which are detailed below.

Low-Cost Brushless DC Motor Drive

The low-cost brushless DC motor drive is designed with simplicity and affordability in mind. It features a minimalistic configuration, consisting of just three transistors and a three-diode converter. This setup restricts the drive to supplying only positive current or voltage to the three-phase motor.

During operation, the induced voltage and current play crucial roles in both the motoring and braking functions of the motor. When 120-degree positive current pulses are delivered to the motor, it initiates a motoring action, causing the motor to rotate in a counter-clockwise direction. Conversely, when these current pulses are shifted by 60 degrees to a total of 180 degrees, the motor transitions into a braking state. This change in the timing of the current pulses effectively alters the interaction between the electrical input and the motor's magnetic field, enabling the shift from rotational motion to a braking mechanism.

Low-Cost Brushless DC Motor Drive: Current Control Mechanism

In the low-cost brushless DC motor drive, the current of phase A is precisely regulated by the thyristor Tr1 and the diode D1. When Tr1 is activated (turned on), the source voltage Vd is connected across winding A. This connection causes the rate of change of the current IA to become positive, meaning the current in phase A starts to increase. Conversely, when Tr1 is deactivated (turned off), the current iA enters a freewheeling state through diode D1. During this freewheeling process, the rate of change of iA turns negative, and the current gradually decays.

Within the 0-120º time period, Tr1 can be switched on and off in an alternating manner. This on-off switching strategy is employed to make the actual current IA closely track a rectangular reference current iA, ensuring that the difference between them remains within a predefined hysteresis band. This precise control helps in maintaining stable motor operation and efficient power transfer.

Single-Phase Brushless DC Motor Drive

The configuration of the single-phase brushless DC motor drive is illustrated in the figure below. For the purpose of analysis, assume that the motor is powered by a half-bridge single-phase converter, which supplies a rectangular current waveform to the motor, as depicted in the accompanying diagram. This specific current waveform plays a crucial role in determining the motor's performance characteristics and operational behavior.

The torque generated by the motor exhibits significant fluctuations, commonly referred to as torque ripple. However, when the motor operates at high speeds, the inertia of the motor-load system acts as a natural filter. This inherent inertia smooths out the torque variations, enabling the motor to maintain a relatively uniform rotational speed despite the presence of torque ripple.