Introduction

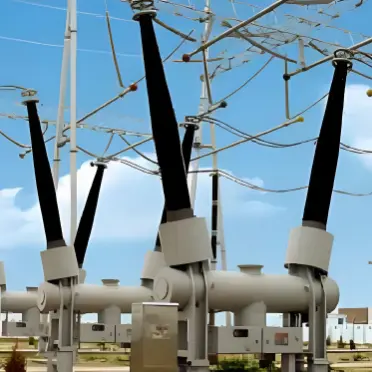

In recent years, Nigeria's power demand has been on the rise with the development of its economy and society. A stable and reliable power transmission system is crucial for its development. The 252kV high - voltage transmission lines play an important role in Nigeria's power grid, and the performance of circuit breakers directly affects the safety and stability of these lines. ABB, as a world - leading electrical equipment manufacturer, has developed a 252kV dead tank SF6 circuit breaker with an advanced arc - quenching chamber system, which is designed to meet the specific needs of the Nigerian power grid and has obtained SONCAP certification, ensuring its compliance with local standards.

Design of the Arc - Quenching Chamber System

Dual - Break Series Arc - Quenching Design

The arc - quenching chamber of the 252kV dead tank SF6 circuit breaker adopts a dual - break series design. In this design, two interrupters are connected in series, and each interrupter is designed to bear approximately 50% of the total voltage, that is, 126kV. This innovative approach significantly reduces the dielectric recovery pressure on a single break.

When a short - circuit fault occurs in the power grid, a large - current arc is generated in the circuit breaker. In the traditional single - break circuit breaker, the entire 252kV voltage needs to be withstood by one interrupter during the arc - quenching process, which puts a huge pressure on the dielectric recovery of the interrupter. However, in the dual - break series design, the voltage is shared between the two interrupters. This not only reduces the electrical stress on each interrupter but also shortens the time required for dielectric recovery. As a result, the arc - quenching efficiency is improved, and the risk of re - ignition of the arc after quenching is greatly reduced.

To ensure the stable operation of the dual - break series system, ABB has also developed a set of precise voltage - sharing control technologies. Special parallel capacitors are installed at both ends of each interrupter. These capacitors are carefully calibrated to ensure that the voltage distribution between the two interrupters is as balanced as possible, even under complex transient fault conditions. This voltage - sharing mechanism further enhances the reliability of the arc - quenching chamber system.

T - Type Piston Pressure Cylinder Structure

The pressure cylinder in the arc - quenching chamber system is designed with a T - type piston structure, which is a key component for generating high - speed SF6 gas flow. When the circuit breaker receives a trip command, the T - type piston starts to move. During the opening process, the piston compresses the SF6 gas in the cylinder to a pressure of 1.2MPa.

This compression process is precisely controlled to ensure that a high - speed gas flow of 600m/s can be generated. The high - speed SF6 gas flow plays a vital role in the arc - quenching process. When the arc is generated, the high - speed gas flow can quickly cool the arc plasma, reduce the temperature of the arc, and remove the ionized particles in the arc channel. By doing so, it accelerates the process of dielectric strength recovery in the arc - extinguishing gap, enabling the circuit breaker to quickly cut off the fault current and complete the arc - quenching task.

The T - type piston structure also has the advantages of simple structure, high mechanical strength, and good sealing performance. The simple structure is conducive to the manufacturing and maintenance of the pressure cylinder, while the high mechanical strength ensures that the piston can withstand the high - pressure and high - speed movement during the operation process. The good sealing performance of the pressure cylinder ensures that the SF6 gas will not leak, maintaining the normal operation of the circuit breaker and ensuring the safety of the power grid.

PTFE - Reinforced Carbon Fiber Nozzles

The nozzle is an important part of the arc - quenching chamber, and its material performance directly affects the service life and arc - quenching performance of the circuit breaker. ABB has selected PTFE - reinforced carbon fiber as the material for the nozzles of the 252kV dead tank SF6 circuit breaker arc - quenching chamber.

PTFE - reinforced carbon fiber has excellent properties such as high temperature resistance, wear resistance, and strong arc - erosion resistance. During the arc - quenching process, the temperature in the arc area can reach extremely high values, often exceeding 10,000 °C. The high - temperature resistance of PTFE - reinforced carbon fiber enables the nozzle to maintain its structural integrity and performance stability under such harsh conditions.

In terms of arc - erosion resistance, this material can withstand at least 2000 full - capacity interruptions (50kA), which greatly extends the maintenance cycle of the circuit breaker. Compared with traditional nozzle materials, PTFE - reinforced carbon fiber nozzles have a longer service life, reducing the frequency of equipment maintenance and replacement, and thus reducing the overall operation and maintenance costs of the power grid.

SONCAP Certification and Compliance

To enter the Nigerian market, the 252kV dead tank SF6 circuit breaker arc - quenching chamber system developed by ABB has successfully passed the SONCAP certification process. The SONCAP certification is a strict assessment program implemented by the Standards Organization of Nigeria to ensure that imported electrical products meet local safety, health, and environmental protection standards.

During the certification process, ABB's product has undergone comprehensive tests in various aspects, including electrical performance, mechanical performance, safety performance, and environmental adaptability. The dual - break series arc - quenching design, T - type piston pressure cylinder structure, and PTFE - reinforced carbon fiber nozzles have all withstood strict scrutiny and verification.

For example, in electrical performance tests, the voltage - sharing performance of the dual - break system, the arc - quenching ability of the circuit breaker under different fault currents, and the dielectric recovery characteristics have all met or exceeded the requirements of Nigerian standards. In mechanical performance tests, the strength and durability of the T - type piston structure, as well as the reliability of the mechanical operation of the circuit breaker, have also been fully recognized.

The successful acquisition of SONCAP certification not only proves the high quality and reliability of ABB's 252kV dead tank SF6 circuit breaker arc - quenching chamber system but also provides a solid guarantee for its wide application in the Nigerian power grid.

Application in Nigeria's Power Grid

The 252kV dead tank SF6 circuit breaker with this advanced arc - quenching chamber system has been successfully applied in several key power transmission projects in Nigeria. In these projects, the circuit breakers have shown excellent performance.

During the operation process, the dual - break series arc - quenching design has effectively dealt with multiple short - circuit faults, ensuring the rapid isolation of faults and minimizing the impact on the power grid. The T - type piston pressure cylinder structure has stably generated high - speed SF6 gas flow, enabling the circuit breakers to complete the arc - quenching task within a short time. The PTFE - reinforced carbon fiber nozzles have also maintained good performance, and no significant erosion or damage has occurred even after many operations.

Thanks to the reliable operation of these circuit breakers, the reliability and stability of the Nigerian power grid have been significantly improved. Power outages caused by circuit breaker failures have been greatly reduced, providing a more stable power supply for industrial production and people's daily lives in Nigeria. At the same time, the long service life and low maintenance requirements of the circuit breakers have also reduced the operation and maintenance costs of the local power department, which is of great significance for the sustainable development of Nigeria's power industry.

Conclusion

The design of the 252kV dead tank SF6 circuit breaker arc - quenching chamber system by ABB, with its innovative dual - break series arc - quenching, T - type piston pressure cylinder structure, and PTFE - reinforced carbon fiber nozzles, provides an excellent solution for Nigeria's high - voltage power transmission. Obtaining SONCAP certification ensures its compliance with local standards, and its successful application in Nigeria's power grid has verified its high reliability and excellent performance. This design case not only meets the current power grid development needs of Nigeria but also provides valuable experience and reference for the design and application of similar high - voltage circuit breakers in other regions. In the future, ABB will continue to optimize and improve this technology to contribute more to the development of the global power industry.