Recently, a Chinese generator circuit breaker manufacturer has successfully developed generator circuit breakers for 1,000MW hydropower and thermal power units, which have passed the group's appraisal and acceptance. Their comprehensive performance has reached the international leading level, filling the domestic gap. This is another major breakthrough following the group's mastery of the technology for large-capacity generator circuit breaker complete sets for 400MW, 600MW, and 800MW units, marking that Chinese generator circuit breaker manufacturers have overcome another key "bottleneck" technical problem and made important contributions to the localization of China's major technical equipment.

Climbing the Peak of Scientific Research, Never Stopping

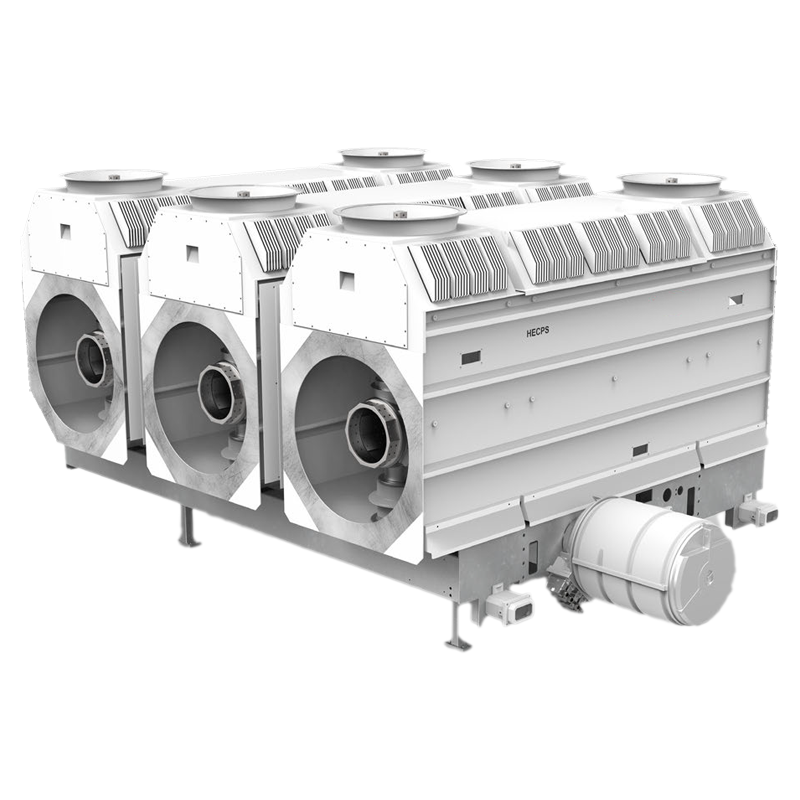

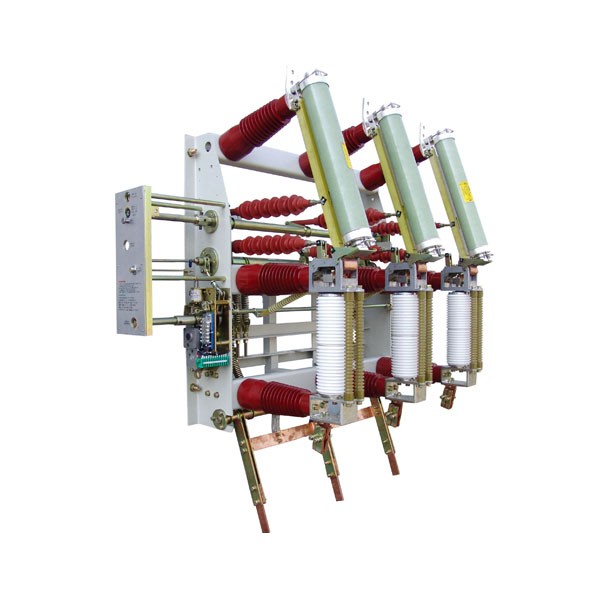

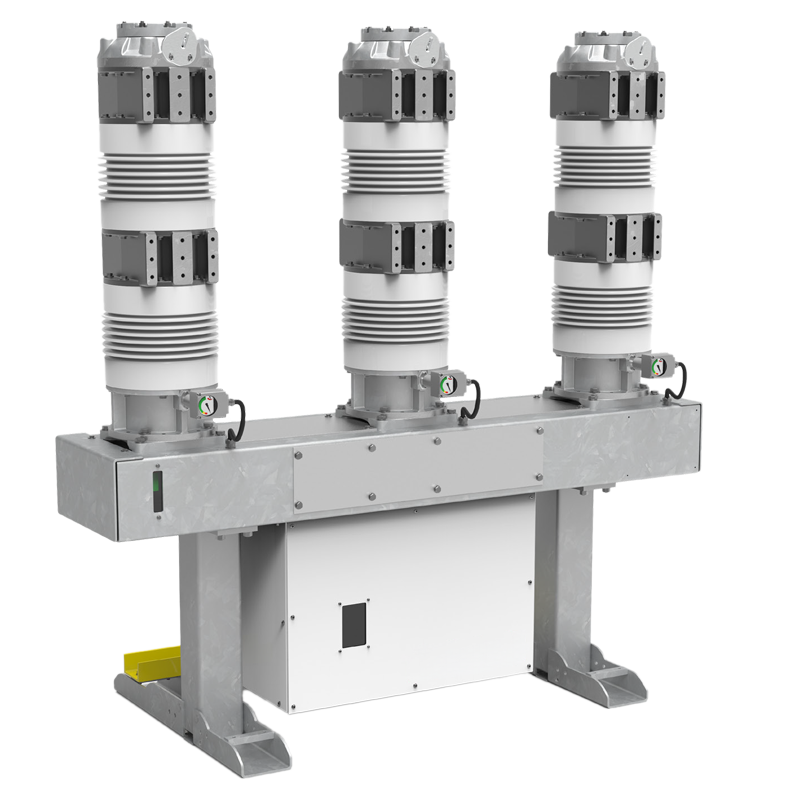

A generator circuit breaker is a high-current circuit breaker installed between the generator outlet and the transformer. It is mainly used to protect generators and transformers, which can effectively improve system safety, facilitate commissioning and maintenance, and bring significant economic benefits. However, the manufacturing technology of this high-end equipment has long been mastered by foreign enterprises, and the country spends a large amount of foreign exchange on imports every year. To realize the localization of major equipment and overcome core technical problems, since 2008, the Chinese generator circuit breaker manufacturer has decided to jointly develop generator circuit breaker products with many groups.

After years of arduous research and development, in 2011 and 2012, the Chinese generator circuit breaker manufacturer successfully completed the development of generator circuit breakers for 600MW and 800MW units respectively; in 2018, it successfully developed generator circuit breakers for 400MW units, initially realizing product serialization and accumulating effective experience for mastering higher-level technologies.

According to the system parameter settings of 1,000MW units, the generator circuit breaker should meet the requirement of a rated short-circuit breaking current of 170kA. "We have not stopped climbing the peak of scientific research, and the technical team must continue to move forward with the development of generator circuit breakers for 1,000MW units," said the project leader. Therefore, starting from 2018, the project team launched the tackling of 170kA generator circuit breakers.

Like other equipment manufacturing, the product development process must go through design, trial production, testing and other links. However, for major key equipment, each link is full of challenges. Without continuous technical reserves and a strong project team, it is extremely difficult to complete the tackling of key core technologies.

For this reason, the Chinese generator circuit breaker manufacturer has continuously increased technical investment and talent training, gave full play to its profound technical accumulation of more than 60 years in the field of power transmission and distribution equipment manufacturing, continuously exerted its resource and talent advantages, and resolutely undertook the important task of researching and developing 170kA generator circuit breakers. From design to simulation (including breaking, temperature rise, mechanics, insulation, etc.), to the strict control of materials, processing technology and assembly technology of key components, they forged ahead courageously and never gave up. With the joint efforts and sincere cooperation of all parties, they finally gnawed this "hard bone".

Mastering Key Technologies, Persevering

Compared with the generator circuit breaker for 800MW units, the 170kA product has a larger breaking current and must meet the control and protection of 1,000MW units in large power stations. Not only has the product level been improved, but the R&D difficulty has also increased exponentially. "But there is no experience for reference in China, and only a very few foreign enterprises master this core technology, making R&D and design extremely difficult," said the designer.

The parameters of the 170kA generator circuit breaker are often several times that of line circuit breakers, which is the key and difficult point in the R&D of large-capacity generator circuit breakers. The rated current is an important parameter for the long-term operation reliability of the product, which needs to solve various problems exposed in high-temperature environments such as conductor temperature rise and insulation aging.

During the rated short-circuit breaking process, extremely high-temperature arc plasma will be generated between the contacts. The temperature between the contacts needs to drop to a certain temperature within a few microseconds when the current crosses zero, which is a necessary condition for the circuit breaker to break, and its difficulty is very high. At the same time, the high-temperature plasma of tens of thousands of degrees between the contacts also causes severe ablation of various components in the arc extinguishing chamber. Therefore, how to design and protect each component against ablation is also a tricky problem.

To meet the dissipation of arc energy of 170kA short-circuit current, a comprehensive innovative design of the arc extinguishing chamber is required. However, the breaking process is a transient process involving multi-field coupling and superposition. The technical accumulation in the industry at home and abroad is very limited, and there is a lack of experience in the research on ultra-large current arcs and arc extinguishing mechanisms. The existing design methods can only provide some references and cannot achieve quantitative design. In the rated peak withstand current test, the electric force generated by the ultra-large current is a great test for the strength, electrical contact performance and transmission structure of the components. For this reason, the project team invested a lot of R&D time and persisted. "After repeated optimization and improvement and multiple rounds of research and testing, the R&D and design plan was finally determined," said the project team members.

Challenging the Test Limit, Pressing Forward with One Momentum

"Even if there are no conditions, we must create conditions to move forward." For more than 60 years, they have been moving forward all the way. The more difficult it is, the more they move forward, and they will not stop until they reach their goal. They have created countless industry miracles, filled many domestic gaps, and laid a fertile ground for the development of 170kA generator circuit breakers. After the R&D plan was determined, the product officially entered the trial production stage.

Since the current parameters of the generator circuit breaker are several times that of conventional switch products, its radial size is much larger than that of conventional products. It is necessary not only to meet the performance requirements but also to ensure the processing and manufacturing accuracy, which brings new challenges to the manufacturing, installation and commissioning of generator circuit breaker products. The trial production team needs to overcome unprecedented difficulties and adopt a combination of various processes to complete this task.

At this time, it was the critical period of national epidemic prevention and control. Many supporting enterprises were shut down, leading to longer processing cycles for components. To reduce the impact of the epidemic on the overall progress of the project, the party members in the project team took the lead actively, raced against time, worked overtime to revise the plan and improve the drawings, winning valuable time for the project progress.

In the test phase, the implementation of the breaking test became another key point. After each test, the recovered prototype will have some irritating gases and dust left, but the project team members ignored these and rushed to the disassembly site immediately to check the state of the prototype after high-current ablation, obtain first-hand data, and provide a basis for subsequent improvements; the project team extensively listened to experts' opinions, continuously analyzed various influencing factors in the test, organically combined the test results with simulation calculations, and formulated a series of technical plans and test plans.

From no breaking point at the beginning to the appearance of breaking points, from having breaking points to realizing full-range breaking, from direct tests to synthetic tests, after several rounds of test research and plan optimization, the bottleneck restricting the project was finally broken. At the same time, many problems such as switching of ultra-large capacity short-circuit current, long-term current carrying of ultra-large continuous current, and manufacturing and processing of key components have been overcome, and new breakthroughs and innovations have been made in the field of design, manufacturing and assembly of national major equipment. In addition, in the process of product development, a strong team of technical talents has been cultivated, laying a solid foundation for the group to lead the industry in core technical fields such as large-capacity generator circuit breakers in China.

Carrying Out Series Development, Stepping into the Forefront

From 2008 to 2021, in more than 10 years, they advanced despite difficulties and persisted. They not only completed the serialization localization of generator circuit breaker complete sets but also improved the research level in the field of ultra-large capacity current breaking and arc extinguishing technology, and achieved significant improvements in the research and development methods and manufacturing processes of large switchgear.

At the same time, the brand's generator circuit breaker complete sets have been successfully applied to national key projects such as Xiangjiaba, Xiluodu, and Wudongde, making due contributions to advancing the localization process of national major equipment. In 2019, the large-capacity generator circuit breakers of the Chinese generator circuit breaker manufacturer were exported overseas for the first time, successfully entering the international market.

● 2008: Launched the development of large-capacity generator circuit breaker complete sets for 600MW units;

● 2011: The large-capacity generator circuit breaker complete sets for 600MW units completed all type tests at the National High-Voltage Electrical Equipment Quality Supervision and Inspection Center, marking that China officially entered the era of R&D of large-capacity generator protection circuit breaker complete sets, making China one of the few countries in the world producing high-end equipment;

● 2012: The large-capacity generator circuit breaker complete sets for 800MW units completed all type tests at the National High-Voltage Electrical Equipment Quality Supervision and Inspection Center;

● 2017: Carried out the serialization development of generator circuit breaker complete sets, and successfully developed large-capacity generator circuit breakers for 400MW units in 2018, making the group's generator circuit breaker series products more complete;

● 2021: Completed the development of large-capacity generator circuit breakers for 1,000MW hydropower and thermal power units, stepping into a higher-end field.

The Chinese generator circuit breaker manufacturer will always keep in mind the "major issues concerning the country", accelerate the "building of an original technology source and a leader in the modern industrial chain", strive to become a proposer of demand, organizer of innovation, provider of technology, and user of the market for original innovation and core technologies, grasp the initiative in technological progress and industrial development, continue to lead the development of the power transmission and distribution industry, and make due contributions to ensuring China's power security and energy security.