1.Ujumbe wa Mwanzo

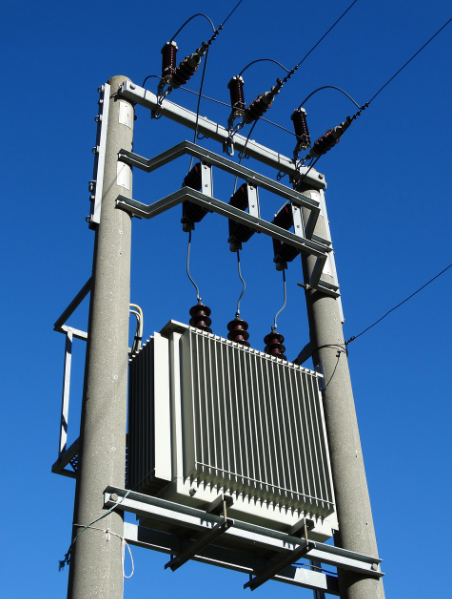

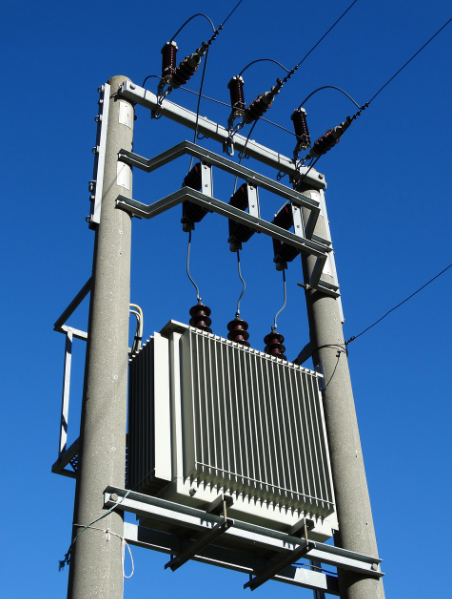

1.1 Hatari ya Haraka ya Kurekebisha Vifaa vya Kubadilisha Umeme

- Ongezeko la Tungo la Mchakato

Wakati wa mchanga, vifaa hivi huendelea kwa ongezeko, kuboresha majiwani (kwa mfano katika maeneo ambayo yameingia katika hatari). Majiwani mengi yanayopata haraka yanaweza kuboresha upungufu wa kipengele cha kuhifadhi (kama kwenye mfumo wa karatasi-mafuta), kuboresha hatari za kutokufanya kazi- vifaa vilivyokosa kunywesha vinaweza kuwa na hatari za kutokufanya kazi zinazofikiwa sana.

- Mashambulio ya Utuaji wa Umeme

Mabadiliko ya kiwango > ±10% ya thamani rasmi yanaweza kuleta mashambulio kwenye vifaa vya utaratibu (vifaa vya daktari, mikataba ya data).Ufukuzi wa harmoniki (THD > 8%) kutoka kwa mchakato wa asili (inverters za PV, chargers za magari ya umeme) yanaweza kupunguza ufanisi wa vifaa (hadima ya 12% kwenye mikabilio ya HVAC).

- Usimamizi na Ujenzi wa Usimamizi

Utambuzi wa mkono kila 6–12 miezi unapoteza ishara za hatari za awali (kama kuchomoa kwa nusu au kusahau mafuta). Gharama za O&M zinajitokezea (25–30% kila mwaka kwa ajili ya nguvu na sehemu), kushusha ROI kwa majengo ya vifaa vya zamani.

1.2 Teknolojia ya Ubunifu inayoweza Kutumaini Usimamizi wa Grid

Tumia sensori za ubunifu kwenye vifaa vya kubadilisha umeme:

Joto: PT100 sensors (±0.1°C) kwa windings;

Mawingu/Aina: Hall-effect sensors (0.5% accuracy, 10kA/400V)

Maangizo: MEMS accelerometers (50mV/g);

Kuchomoa kwa Nusu: Ultrasonic sensors (20 - 150kHz);

Mazingira: Humidity/CO₂ sensors

- Technology-Integrated Terminal (TTU)

TTU iliyotumia computing ya edge inafanya:

Multi-protocol Acquisition: IEC61850, Modbus;

Analytics: FPGA for harmonics, LSTM for load forecasts

Security Architecture: TLS 1.3, HSM;

Control Capabilities: Auto-reclosing, OLTC regulation

- Nidhamu ya Takwimu ya Kutathmini

Nidhamu ya AI-imarishwa inafanya:

Multi-source Fusion: Combines vibration, DGA, thermal data;

Fault Prognostics: CNN for classification, Monte Carlo for RUL

Optimization Engine: Genetic algo for scheduling, digital twins;

Compliance Management: IEC60599, NERC audits

1.3 Badiliko ya Ubunifu kutatua Matatizo ya Grid ya Umeme

- Kuboresha Upatikanaji wa Umeme

Utambuzi: Tumia PT100 sensors (±0.5°C) kwa winding temp, UHF sensors (300 - 1500MHz) kwa partial discharge, na MEMS accelerometers (50mV/g) kwa vibration.

Diagnosis: LSTM - based detection (10,000+ cases), digital twin (error <0.3%).

Self - Healing: IEC61850 for breaker coord., reactive power comp. for voltage.

- Kuboresha Uhamiaji wa Nishati

Renewables: Mitigate PV/wind with MPPT, coord. batteries (SOC ±2%).

Load Mgmt: Reinforcement - learning forecast (error <3%), tariff response (peak shaving +18%).

Power Quality: Active filtering (THD <3%), voltage sag comp. (<20ms).

- Punguza Gharama za Usimamizi na Ujenzi

Faults: Transformer - specific detection (AUC >0.95), RUL pred. (±5%).

Decision: Prioritize with FMEA + cost - benefit, optimize inventory (accuracy >90%).

Remote: 5G param. adj., AR - assisted (98% loc. accuracy).

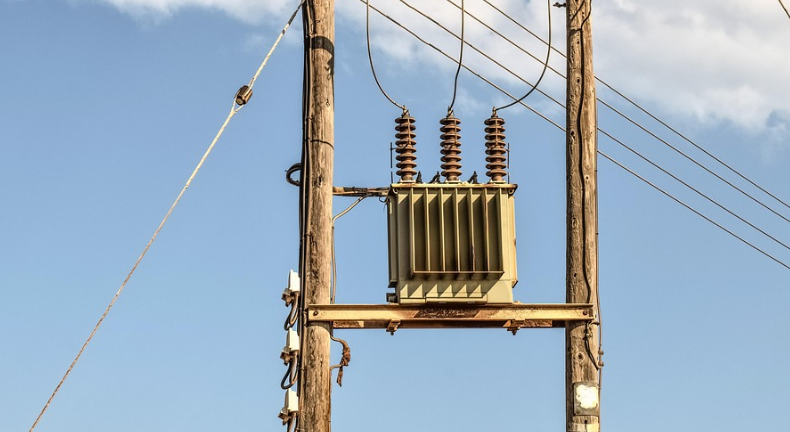

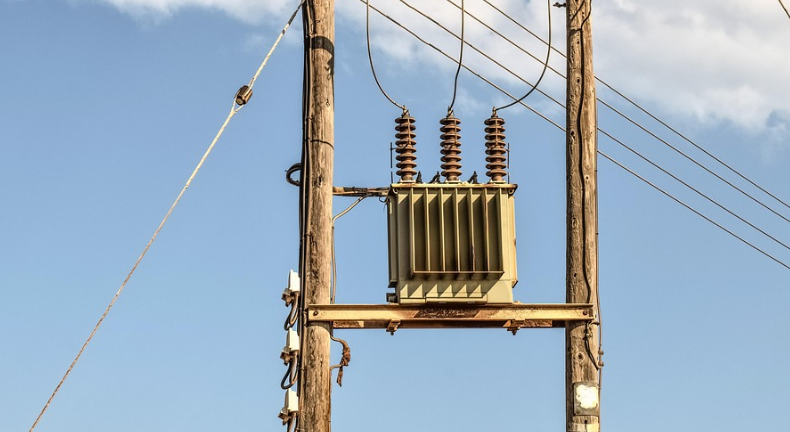

2.Matatizo yanayohusiana na vifaa vya kubadilisha umeme

2.1 Ongezeko la Tungo la Mchakato

Ongezeko la muda mrefu wakati wa mchanga linaleta joto la vifaa vingi, kuboresha uzalishaji wa kipengele cha kuhifadhi na kuboresha hatari za kutokufanya kazi, kusababisha mafuriko na miaka minne.

- Mshambulio wa Utuaji wa Umeme

Mabadiliko makubwa ya kiwango, ukosefu wa utaratibu, na ufukuzi wa harmoniki (kutoka kwa nishati mpya au mchakato asili) hunyanyasisha ufanisi wa vifaa na kusababisha malipo.

- Usimamizi na Ujenzi usiofaao

Utambuzi wa muda unaleta ishara za hatari za awali, kusababisha mabadiliko yanayohitajika na gharama zinazozidi.

2.2 Maombi tofauti ya Umeme

Wateja wanahitaji utaratibu wa umeme wa kiwango chenye kiasi kikubwa. Miundombinu ni utaratibu wa kiwango (±1% fluctuation), utaratibu wa kiwango (±0.1 Hz deviation), na ufukuzi mdogo wa harmoniki (THD < 5%). Hii ni kwa sababu ya vifaa vya digital vya utaratibu na ustawi wa kiwango.

- Matatizo ya Transformers Za Kiwango Chache

- Haoni bora mabadiliko ya mchakato kwa sababu ya muktadha wa impedance.

- Wanatumia filters wa LC passively tu, si kutosha.

- Hawana ubora wa kutumaini kiwango cha mizizi kwa nishati mpya.

- Hawana ubora wa kutumaini mizizi tofauti kutoka kwa nishati za mizizi.

- Transformers za ubunifu na electronics na modules za compensation zinahitajika.

- Matatizo ya Integretion ya Nishati Mpya

Nishati mpya inajitokezea kwa kasi (solar PV at +35% CAGR, wind at +18% CAGR):

- Intermittency hutengeneza mabadiliko ya utaratibu (0.2 - 0.5 Hz in weak grids).

- Inverters za PV hutumia componenti za DC, kutengeneza sync ya grid.

- Capacitive reactive power inaweza kuleta overvoltages wakati wa kiwango kidogo.

- Harmoniki kutoka kwa inverters zenye mistari kadhaa (up to 11th order).

2.3 Complexification of Power Grid Structure

- Complexification of Power Grid Structure

With the development of smart grids and micro-grids, and the integration of distributed energy resources into the grid, the power grid now encompasses a diverse array of equipment and intricate wiring configurations.

- High Difficulty in Operation and Maintenance

The increasing complexity has significantly escalated the challenges in operation and maintenance, driving up associated costs. Delays in issue resolution can potentially trigger the spread of faults, leading to more severe consequences.

- Efficient and Precise Operation and Maintenance

To address these issues, it is imperative to innovate operation and maintenance management models. This involves enhancing the professional capabilities of operation and maintenance personnel and introducing intelligent operation and maintenance tools and advanced technologies.

3.Realization effect

3.1 Technical-Driven Efficiency Revolution

- Real-time Operation and Maintenance Monitoring

By leveraging sensors and Internet of Things (IoT) technologies, real-time monitoring and remote control of the operation status of distribution transformers can be realized. This significantly enhances the timeliness and accuracy of operation and maintenance work.

The intelligent system is capable of quickly identifying faults and triggering the alarm mechanism. As a result, it shortens the time required for fault detection and response, minimizes economic losses, and ensures the stable operation of the power supply.

By applying big data analysis and AI, potential equipment failures can be predicted in advance. Accordingly, preventive maintenance plans are made. This not only cuts operation and maintenance costs but also prolongs equipment service life and boosts its operational efficiency.

With intelligent transformation, power enterprises can achieve fine-grained management of power supply services. This leads to an improvement in the reliability and stability of power supply, ultimately providing users with a better power-using experience.

3.2Digital Upgrade of Power Grid Resilience

- Real-Time Data Collection

IoT sensors at substations, transformers, and distribution nodes collect grid data. Multi-channel systems integrate SCADA, EMS, and PMU-PDC to synchronize time-stamped data. Edge computing uses wavelet transforms to preprocess data, filtering noise while keeping key transient features.

Self-healing algorithms isolate faults in under 200ms. Digital twins precompute reconfiguration strategies. Coordinated SCADA-EMS actions maintain voltage stability.

AI platforms correlate real-time data with historical failures. Machine learning models predict component degradation for maintenance. Risk scoring systems prioritize vulnerabilities with N-1 analysis and simulations.

Phasor measurement networks detect low-frequency oscillations. Blockchain ensures data integrity. Reinforcement learning optimizes preventive actions based on real-time risks and forecasts.

3.3Strategic Pillars for Industry Transformation

AI-driven platforms optimize end-to-end services via predictive analytics and resource allocation. Edge computing ensures sub-50ms latency for key decisions on load balancing and fault tolerance.

- Digital Transformation Acceleration

Blockchain-enabled AMI and 5G-IoT networks enable secure real-time data exchange. Digital twin platforms simulate over 10,000 grid nodes, optimizing dispatch with reinforcement learning.

- Advanced Monitoring & Prediction

Smart transformers with 1kHz sensors do microsecond-level transient analysis. Hybrid ML models (LSTM-CNN) predict winding and bushing issues with 98% accuracy, cutting unplanned outages by 40%.

- Innovative Digital Services

AI-powered aggregators offer dynamic pricing and demand response. VPP platforms aggregate 500MW+ resources for ancillary services, generating over $12M annually.

4.Future Prospects

4.1 Continuous Optimization & Innovation of Intelligent Technologies

- Technology Integration & Enhancement

Hybrid AI (CNN-LSTM) combines with 5G-IoT sensor networks (vibration/temperature) for multi-D monitoring. Edge computing preprocesses data with federated learning, detecting partial discharge with 99.2% accuracy and <50ms latency.

- Intelligent Operation Management

Digital twins simulate transformer heat under different loads (0-120% capacity) to optimize cooling. Predictive maintenance models (aging index) cut unplanned outages by 35% via N-1 analysis.

- Autonomous Diagnosis & Self-Recovery

Blockchain-secured logs help cross-device anomaly detection with federated neural nets. Self-healing isolates faulty windings in <150ms by IED coordination, and drone thermal imaging checks repairs.

4.2Widespread Application of Intelligent Transformers

- Advanced transformer tech aids decarbonization:

- Dynamic impedance matching cuts renewable curtailment losses by 22%.

- Phase-shifting mitigates harmonics, meeting IEC 61000-4-7.

- Vacuum distillation recovers 95% of insulating oil.

- Intelligent transformers expand from urban grids to various scenarios:

- In industrial IoT, 10kHz-sampled vibration sensors on wind turbine gearboxes enable predictive maintenance.

- Cross-border energy corridors use substations with blockchain for transactive energy.

- Rural microgrids adopt solar-compatible transformers with MPPT, reaching 98.5% efficiency.

- Smart transformers optimize energy use:

- Digital twins simulate 120% overload thermal profiles.

- AI-driven load forecasting is 97% accurate, reducing overload risks.

- LoRaWAN wireless mesh covers 15km for distributed monitoring.