- Introduction

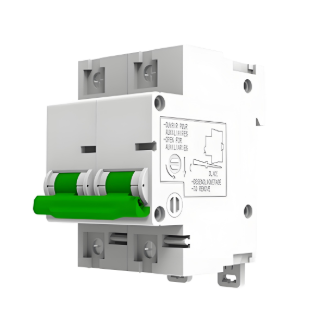

The Fault Current Limiter (FCL) is a critical protection device in modern power systems. It is designed to rapidly limit fault currents during system failures such as short circuits, thereby protecting key equipment in the grid from damage and ensuring stable system operation. However, during actual operation, the current limiter itself may also fail due to various reasons. To ensure its reliability, systematic prevention and maintenance strategies must be developed for common fault types. This document aims to provide a comprehensive set of solutions for fault current limiters from four core perspectives: overcurrent, overheating, insulation aging, and mechanical failures.

2. Problem Analysis and Solutions

Perspective 1: Solutions for Overcurrent Faults

Problem Analysis: Overcurrent faults are usually caused by sudden short circuits in the grid or a sharp increase in connected loads. Instantaneous high currents can exceed the design withstand capacity of the current limiter, leading to permanent damage to its core components such as power electronic devices (e.g., IGBTs), fast switches, or superconducting units.

Solutions:

- Real-time Monitoring and Early Warning System: Install high-precision current sensors and monitoring devices to continuously track line currents. Trigger an early warning signal when the current approaches but has not yet exceeded the safety threshold, providing intervention time for maintenance personnel.

- Multi-Level Protection Configuration: Establish a multi-level protection system. Ensure that the ratings of upstream circuit breakers or fuses match the withstand capability of the current limiter. During overcurrent events, backup protection devices should operate before or in coordination with the current limiter to promptly interrupt the circuit.

- Periodic Calibration and Setting Review: As grid structures change and loads increase, regularly review the current limiter’s operating current settings to ensure they align with the current grid conditions, preventing false or failed operations.

Perspective 2: Solutions for Overheating Faults

Problem Analysis: Overheating is a primary cause of reduced lifespan and sudden failures in electronic equipment. For fault current limiters, prolonged high-load operation, poor heat dissipation, or high ambient temperatures can lead to accumulated heat in internal components, resulting in performance degradation or even burnout.

Solutions:

- Enhanced Temperature Monitoring: Deploy temperature sensors at key heat-generating points within the current limiter (e.g., reactors, power resistors, power semiconductors) to enable real-time temperature display and over-temperature alarms.

- Active Cooling System Design: Optimize heat dissipation structures by adopting active cooling solutions such as forced air or liquid cooling. Ensure adequate installation spacing, clear surroundings, and unobstructed ventilation. Regularly clean dust from fans and heat sinks to maintain cooling efficiency.

- Use of High-Temperature Resistant Components: During device selection or replacement, prioritize components with high junction temperatures and excellent thermal stability to enhance the overall heat resistance of the equipment.

Perspective 3: Solutions for Insulation Aging Faults

Problem Analysis: Insulation materials gradually degrade under long-term exposure to electric fields, thermal stress, and environmental factors (e.g., humidity, dust, chemical contamination). This leads to reduced insulation strength, increased leakage currents, partial discharges, or even breakdown short circuits.

Solutions:

- Preventive Testing and Periodic Replacement: Strictly implement preventive testing plans. Regularly measure insulation resistance and dielectric loss factors using tools such as megohmmeters and dissipation factor testers to assess insulation health. Develop periodic replacement schedules for insulation components based on manufacturer recommendations and operating environments.

- Enhanced Environmental Adaptability Design: For current limiters operating in humid or heavily polluted environments, select models with moisture-proof, anti-condensation, and anti-pollution flashover features. Use sealed structures, insulating gas injection, or special insulation materials (e.g., silicone rubber) to improve protection levels.

- Condition-Based Maintenance and Cleaning: Incorporate insulation inspections into routine maintenance procedures. Use infrared thermal imaging to detect localized hot spots. Perform regular power-off cleaning to remove contaminants from insulation surfaces, keeping them clean and dry.

Perspective 4: Solutions for Mechanical Faults

Problem Analysis: Mechanical faults primarily occur in current limiters equipped with mechanical components such as fast vacuum switches or repulsion mechanisms. Common issues include mechanism jamming, spring fatigue, contact wear, and poor contact, which can prevent the current limiter from operating reliably within milliseconds.

Solutions:

- Systematic Mechanical Maintenance: Establish a regular mechanical maintenance regimen. This includes cleaning operating mechanisms, replenishing or replacing lubricants, checking for loose fasteners, measuring contact wear and overtravel, and ensuring mechanical flexibility and reliability.

- Selection of High-Reliability Products: During procurement, prioritize brands and products with mature designs, extensive practical validation, and long mechanical lifespans.

- Improved Operating Environment: Avoid installing equipment in extreme environments with strong vibrations, significant temperature fluctuations, or corrosive gases. If unavoidable, implement auxiliary measures such as vibration damping, temperature control, and sealing.

3. Comprehensive Implementation Recommendations

- Establish a Full Lifecycle Management System: Implement full lifecycle management for fault current limiters, from device selection, installation, and commissioning to operation, maintenance, and decommissioning. Maintain detailed health records.

- Train Professional Maintenance Teams: Provide specialized training for maintenance personnel to ensure they master the inspection, maintenance, and fault-handling skills outlined in this document.

- Spare Parts Management: Stock critical components and wear-prone parts to enable timely replacements during failures and minimize downtime.

4. Conclusion

The stable operation of fault current limiters is crucial for grid security. By implementing the comprehensive solutions addressing overcurrent, overheating, insulation aging, and mechanical faults outlined above, and establishing a management system focused on "prevention first, maintenance second," the operational reliability and service life of fault current limiters can be significantly enhanced. This will minimize the risk of unexpected downtime and provide a solid foundation for the safe, stable, and efficient operation of the power system.