| Brand | ROCKWILL |

| Model NO. | 24kV Single Phase Pole Mounted 32 Step Automatic Voltage Regulator |

| Rated voltage | 24kV |

| Rated frequency | 50/60Hz |

| Rated capacity | 125kVA |

| Series | RVR |

Description

The 24kV single-phase pole-mounted 32-step automatic voltage regulator, based on advanced on-load voltage regulation technology, enables precise 32-step voltage adjustment. Equipped with an intelligent monitoring module, it can capture subtle voltage fluctuations in the distribution network in real time, respond quickly, and automatically switch voltage regulation taps to adapt to complex and changeable distribution network conditions.

Designed for pole mounting, it is compatible with different pole types and installation environments, eliminating the need for additional complex foundations and greatly simplifying the deployment process. With fully automated operation—from voltage detection and tap switching to voltage regulation execution—no manual intervention is required, which not only improves operation and maintenance efficiency but also avoids human operation errors.

It stably outputs 24kV single-phase voltage, effectively suppressing voltage deviations, flicker, and other issues, providing continuous and reliable power support for end devices and user loads in the distribution network. This helps the distribution network achieve more efficient and reliable power distribution and operation in scenarios such as urban-rural power supply and small commercial-industrial power supply, contributing to the construction of an intelligent and stable power distribution and consumption ecosystem.

Product Features

Precision Voltage Regulation

32-step voltage adjustment (±10% range, ~0.625% per step) for smooth and accurate voltage control.

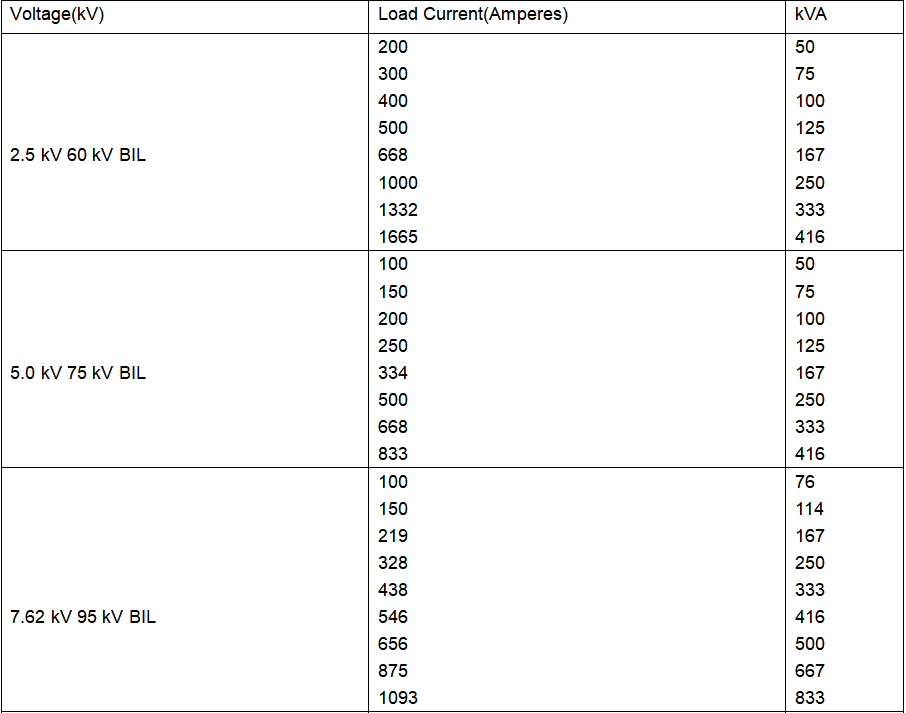

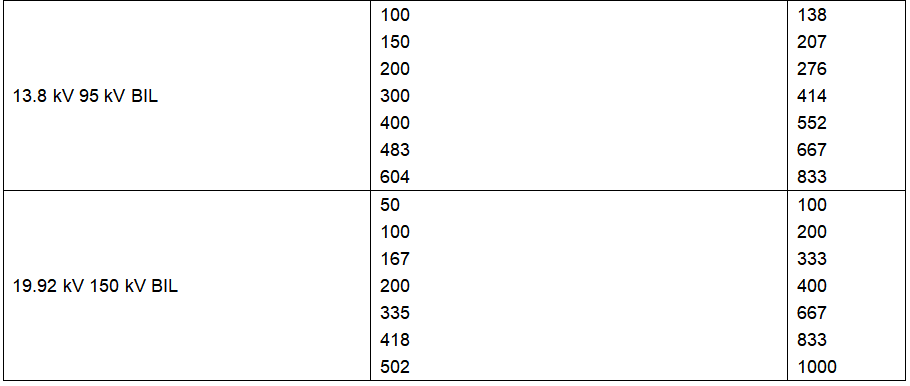

Suitable for single-phase power distribution systems (2400V to 34,500V, 50/60Hz).

Robust Construction

Oil-immersed auto-transformer design ensures durability and efficient heat dissipation.

High-creep porcelain bushings and MOV-type arresters provide superior insulation and surge protection.

Smart Control & Monitoring

RVR intelligent controller with GPRS/GSM/Bluetooth for remote monitoring and adjustments.

Real-time voltage & current sampling via built-in sensors (CT/PT inputs).

Key Advantages

High Reliability: Oil-immersed construction and conformally coated PCBs ensure long-term stability in harsh environments.

Wide Compatibility: Supports 60Hz & 50Hz systems with voltage ratings up to 34.5kV (200 kV BIL).

Automated & Remote-Controlled: Smart controller enables real-time adjustments via mobile or SCADA systems.

Enhanced Safety: Built-in fault protection and pressure/oil monitoring prevent catastrophic failures.

Low Maintenance: Modular design simplifies servicing (e.g., tap changer motor, replaceable bushings).

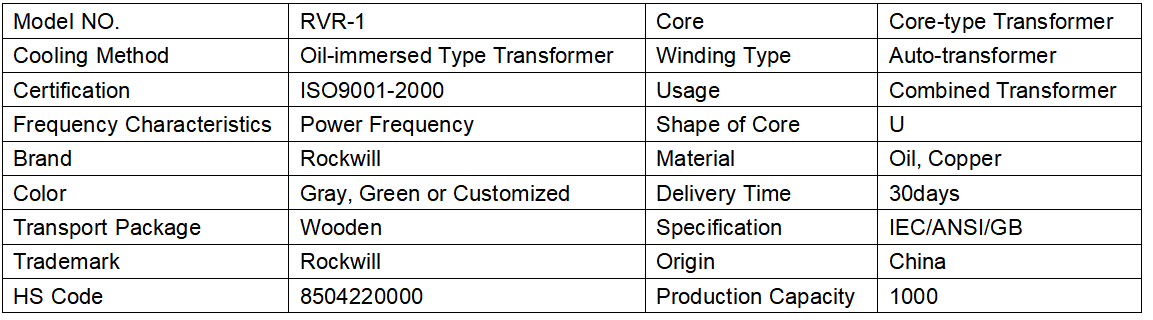

Technical Specifications

Typical Applications

Utility Grids:Compensates for voltage drops in rural or long-distance distribution lines.

Industrial Power Systems: Stabilizes voltage for factories with fluctuating loads.

Renewable Energy Integration:Smooths voltage variations in solar/wind farm connections.

Commercial & Municipal Networks:Ensures stable power for hospitals, data centers, and water treatment plants.

Mining & Offshore Installations:Handles high-voltage fluctuations in remote or demanding environments.

Why Choose the RVR-1?

The RVR-1 Automatic Voltage Regulator combines precision, durability, and smart control to optimize power distribution efficiency. Its 32-step fine-tuning capability ensures stable voltage delivery, while remote monitoring minimizes downtime. Ideal for utilities and industries requiring reliable voltage regulation in medium-voltage networks.