Maɓallu mai tsafta ta hanyar ƙwarewa suna da amfani da su a matsayin yanayi mai muhimmanci a cikin fadin kungiyoyin tsari (MHV). Su na iya zama yanayi masu muhimmanci a bangaren kungiya, musamman a cikin shirye-shirye da ke 11kV da 33kV. An yi waɗannan maɓallu daga balaƙi masu yawan ƙwarewa. Daga cikinsu, wanda ya fi shahara ita ce ƙwarewar tsafta. Don maɓallun ma'aikata, ana kunna ƙwarewar tsafta a tsakiyar ƙwarewa.

Ana kofin waɗannan maɓallun zuwa sana'ar daɗi na ma'aikatar a kan tsakiyar ƙwarewa - fibreglass - resin - cast operating rods, wanda suke an kofin zuwa sana'ar gang operating rod na metal - steel. Sana'ar daɗi na maɓallun ma'aikata ta hanyar ƙwarewa ta gudanar da aiki a kan sabon ƙwarewa, ana iya samun spring - type design, wanda ana kunni a cikin sabon ƙwarewa. Saboda amfani da balaƙi masu yawan ƙwarewa, yana da kyau a bayyana tsohon daɗi da ƙwarewar da sana'ar daɗi a kan al'amuran da maɓallun za su iya aiki a kan su. Wannan bayyana yana taimakawa a fara aiki da lafiya, kuma sahihin fadin kungiyoyin tsari wadanda suke mafi girma a kan su.

Bayyanai masu amfani da maɓallun, musamman bayyanai tashin tafukar da tashin tufafin dole, suna cikin 6.101.3 of IEC 62271 - 100[1]. Don al'amuran da suka da tafukar tashi, alamar da suke da shawarwari da tushen tafukar da tushen tufafi shine - 50°C zuwa + 40°C, don al'amuran da suka da tufafin dole, alamar da suke da shawarwari da tushen tafukar da tushen tufafi shine - 5°C zuwa + 50°C. A mayar da 1000 metres, alamar da suke da shawarwari da tushen tafukar don bayyana tafukar tashi shine - 10°C, - 25°C, - 30°C, da - 40°C. A cikin al'amuran da maɓallun za su iya aiki, wannan bayyana tafukar tashi, ya kamata a yi nasarar da tashin tafukar tashi. A India, akwai wurare da suka da tafukar tashi a wurare kamar Kashmir, Himachal Pradesh, Uttarakhand, da Sikkim.

Tafukar tashi zai iya ƙara zuwa -25°C. A cikin wurare, masu ilimin tafukar tashi suna ƙaretsa da abubuwan da suke haifar da tafukar tashi kamar wind chill da snow blizzards. A ranar tufafi, a duk wurare na India, tufafi zai iya ƙara zuwa 50°C. Mai sarrafa maɓallun da suke fitowa a wurare da suka da tafukar tashi ko tufafi, ya kamata su tafi yadda aiki suke zama a cikin al'amuran da suke da tafukar tashi ko tufafi.

Wannan rubutu ya nuna yadda aiki na maɓallun 36 kV - class outdoor vacuum circuit breakers (VCBs) a cikin al'amuran da suka da tafukar tashi ko tufafi a cikin IEC 62271 - 100. Bayyanai da aka nuna a cikin wannan rubutu sun hada da (a) bayyana tafukar tashi da (b) bayyana tufafi. Kuma rubutu ya duba tushen aiki, tushen ƙarin daɗi da tushen ƙarin daɗi da tushen ƙarin daɗi na sana'ar daɗi na maɓallun 36 kV - class outdoor VCB.

Don in taimaka a neman yadda aiki na maɓallun ƙwarewa a cikin tafukar tashi, an samun bayyana da aka nuna a IEC - 62271 - 100. Wannan bayyana IEC ya nuna cewa don maɓallun da suke da tsakiya ta ɗaya da sana'ar daɗi na mutane, ya kamata a yi bayyana ƙarin daɗi. Don maɓallun da suke da tsakiya ƙarin da sana'ar daɗi masu ƙarin, ya kamata a yi bayyana ƙarin daɗi. Idan akwai ƙananan a kan bayyana, za a iya bayyana maɓallun ƙarin daɗi a kan ƙarin daɗi, idan ba a tabbas da maɓallun a kan bayyana:

Ƙaramin ƙarin daɗi

Ƙaramin ƙarin daɗi

Ƙaramin ƙarin daɗi

A cikin bayyana, babu ƙoƙari, ƙaramin ƙarin daɗi, ko ƙaramin ƙarin daɗi. Idan maɓallun ya ba da buƙata da ya fi yiwu, za a ƙaramin ƙarin daɗi a cikin bayyana.

Koyarren bayyana za a yi waɗannan:

Tushen ƙarin daɗi

Tushen ƙarin daɗi

Tushen ƙarin daɗi

Tushen ƙarin daɗi (idandansa ƙarin daɗi)

Tushen ƙarin daɗi

Tushen ƙarin daɗi

Tushen ƙarin daɗi

Tushen ƙarin daɗi

Bayyana ƙarin daɗi idan ya fi yiwu

Gas pressure idan ya fi yiwu

Resistance of the main circuit

Tushen ƙarin daɗi

Waɗannan koyarren bayyana za a tattauna a:

Alamar da suke da shawarwari da tushen ƙarin daɗi

Alamar da suke da shawarwari da tushen ƙarin daɗi

Alamar da suke da shawarwari da tushen ƙarin daɗi

Alamar da suke da shawarwari da tushen ƙarin daɗi

Pressure - changed parameters are not applicable for VCBs since the contactor is housed in vacuum bottles and this vacuum interrupter assembly is encapsulated in air - insulated porcelain housing for outdoor application.

Tartibin bayyana tafukar tashi an nuna a cl. 6.101.3.3 of IEC 62271 - 100. Initial operating characteristics [1.4] are characterized after exposing the breaker at 20 ± 5°C. After initial examination with the circuit breaker in closed position the temperature will be decreased to the minimum ambient air temperature as per the temperature category. The breaker will be kept in closed position for 24 hours with anti - condensation heaters on. After 24 hours the breaker is opened & closed at rated values of supply voltage. The opening and closing time are recorded to establish low - temperature operating characteristics. Then supply to anti - condensation heaters is disconnected for a period of time (t₁) as specified by the manufacturer, subject to a minimum of two hours. During this interval, alarms are admissible but lockouts are not admissible. After time t₁ the breaker is opened and the opening time is recorded. If possible, the mechanical travel characteristics are also measured to allow assessment of interrupting capacity.

The breaker will be in open position for 24 hours after which the breaker will be closed and opened. Then 50 CO operations are performed with the first three CO operations performed without any delay. Balance CO operations are performed as C - tₑ - O - tₑ. Time tₑ is the time period between operations. A 3 - minute interval will be allowed for each cycle or sequence. After completion of 50 CO operations the temperature of the climatic test chamber is raised at the rate of 10 K/hour. During the transition period, C - tₑ - O - tₑ and O - tₑ - C - tₑ - O operations are performed such that the breaker remains in closed and open position for 30 minutes period between the operating sequences. After the circuit breaker stabilizes to ambient temperature a repeat measurement of the operating characteristics is carried out at 20 ± 5°C for comparison with the initial characteristics at 20 ± 5°C.

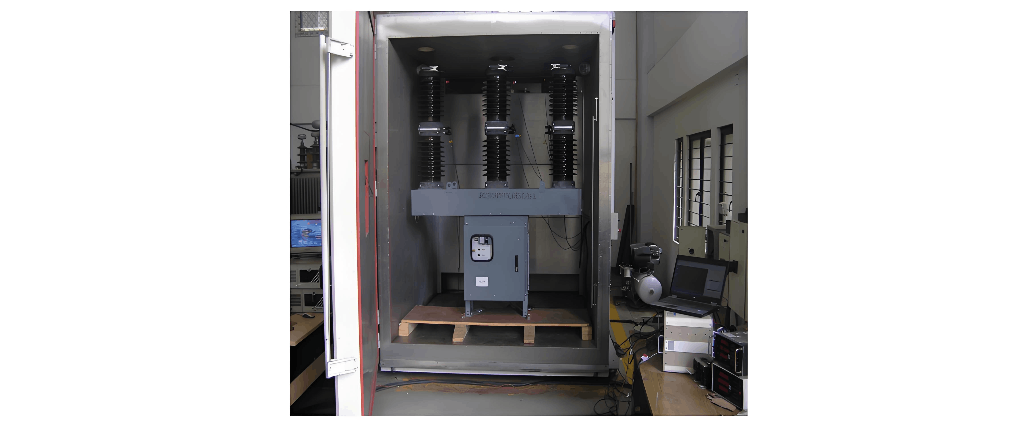

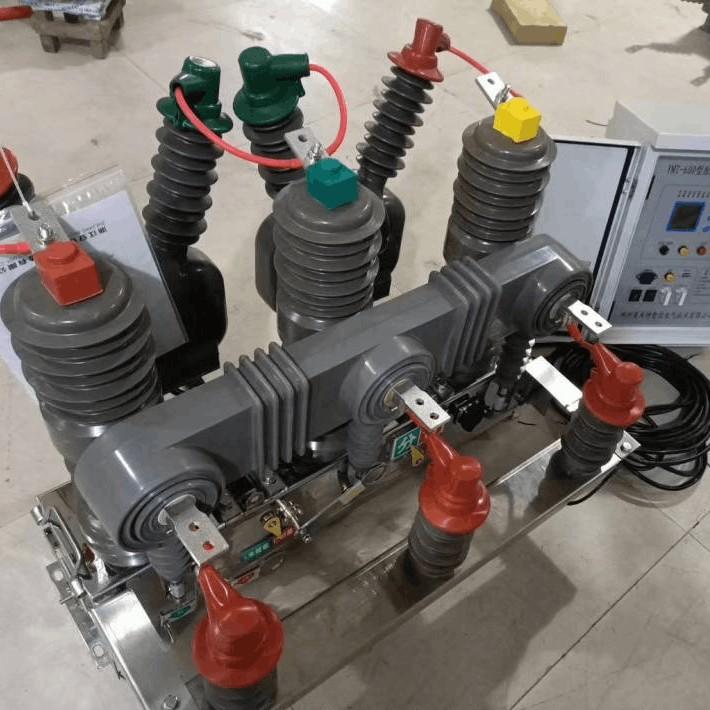

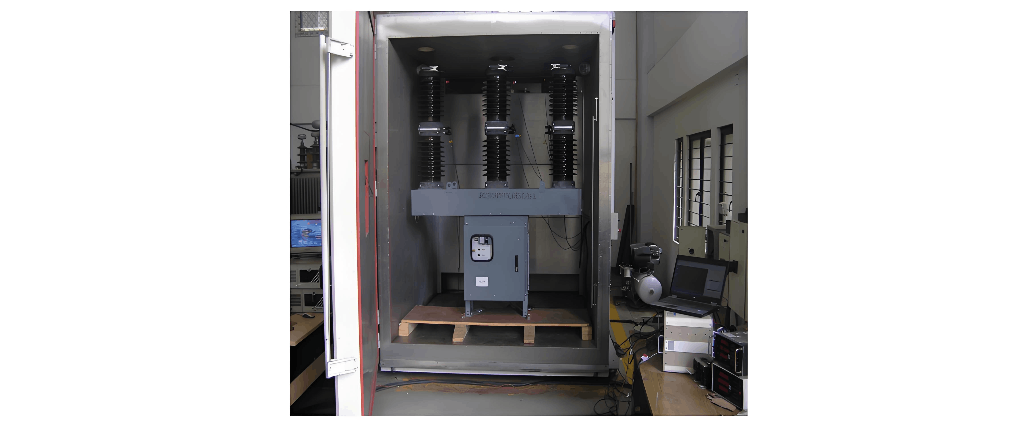

CPRI has been conducting low - and high - temperature tests on Medium High Voltage (MHV) switchgear up to 36 kV for over ten years. Figure 1 shows a typical test arrangement for an outdoor 36 kV vacuum circuit breaker (VCB) installed in the test chamber for high - and low - temperature testing.

Experimental results for a 36 kV - class outdoor VCB during low - and high - temperature tests are presented. The VCBs tested were equipped with spring operating mechanisms.

The high - temperature test was performed at +55°C, and the low - temperature tests were performed at -10°C and -25°C. The following characteristics were examined to analyze the performance of the VCB:

Closing and Opening time (Operating Time):Closing time is defined as the interval of time between energizing the closing circuit, with the circuit breaker in the open position, and the instant when the contacts touch in all poles.Opening time of a circuit breaker is defined as the interval of time between the instant of energizing the opening release, with the circuit breaker in the closed position, and the instant when arcing contacts separate in all poles.

To obtain volumetric data, the average value of the operating times of all three poles is considered for comparison purposes. Since the time spread between poles has been compared, the maximum change between the maximum and minimum time of individual poles is automatically represented.

a) Time Spread between poles

b) Characteristic of the recharging device, such as recharging time and current consumption.

c) Change in operating characteristics in reference to the initial operating characteristics.

The performance of the breakers during high - and low - temperature tests has been compared with reference to the above - mentioned characteristics, and the results are discussed in the subsequent sections.

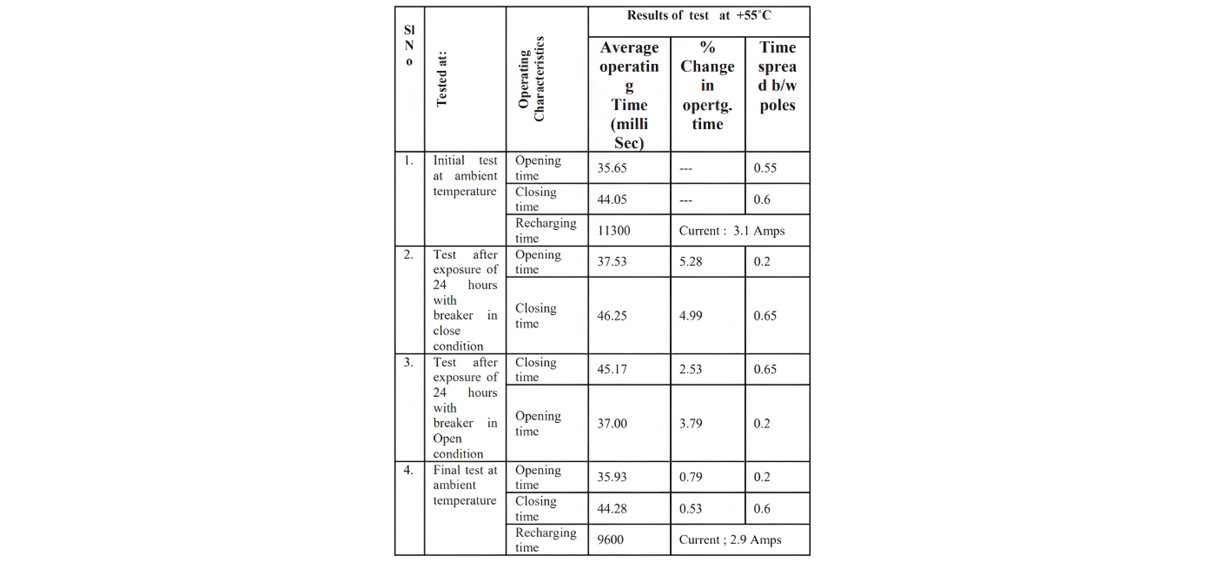

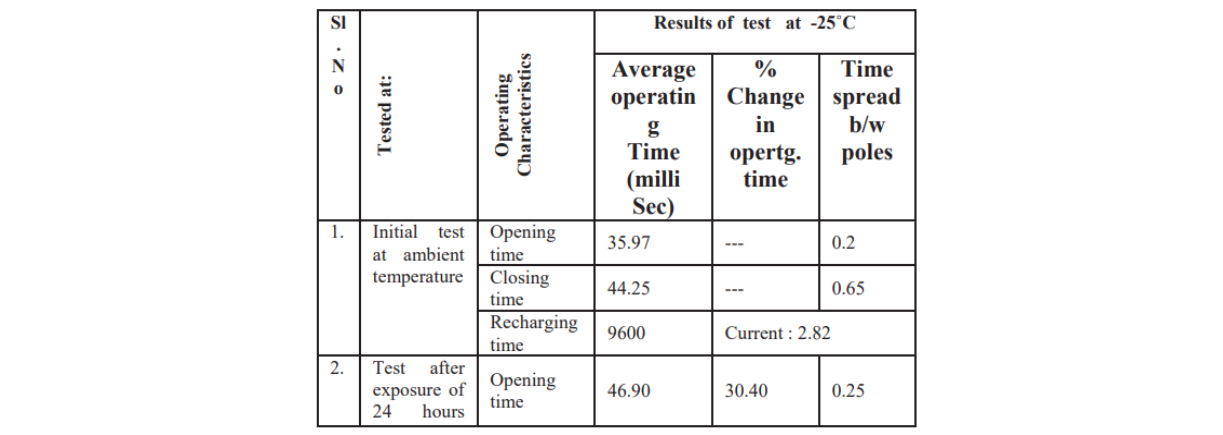

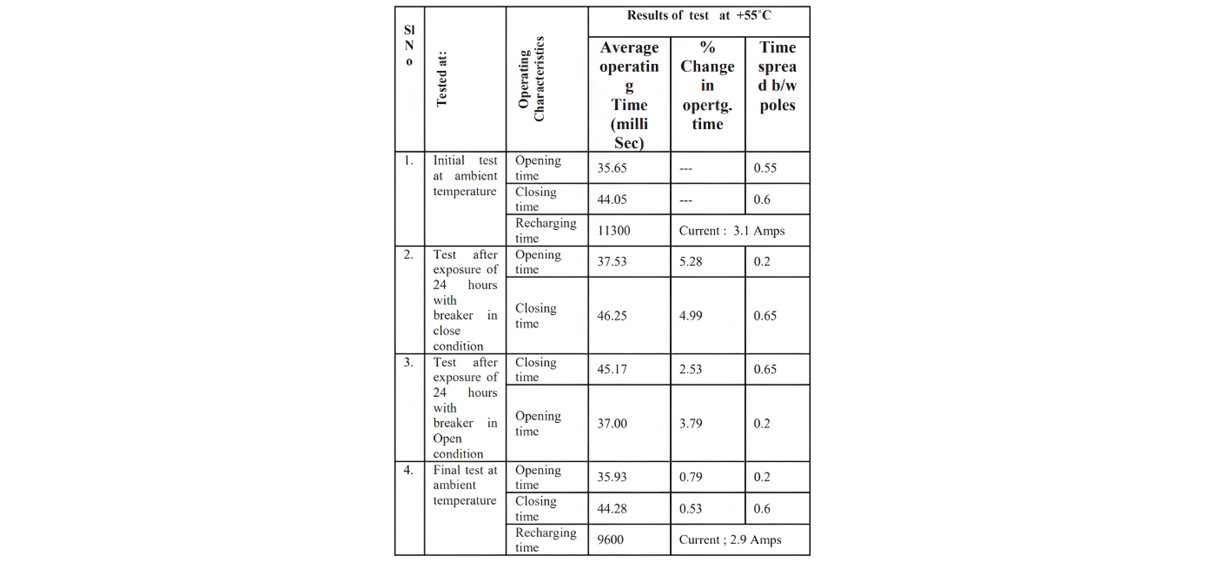

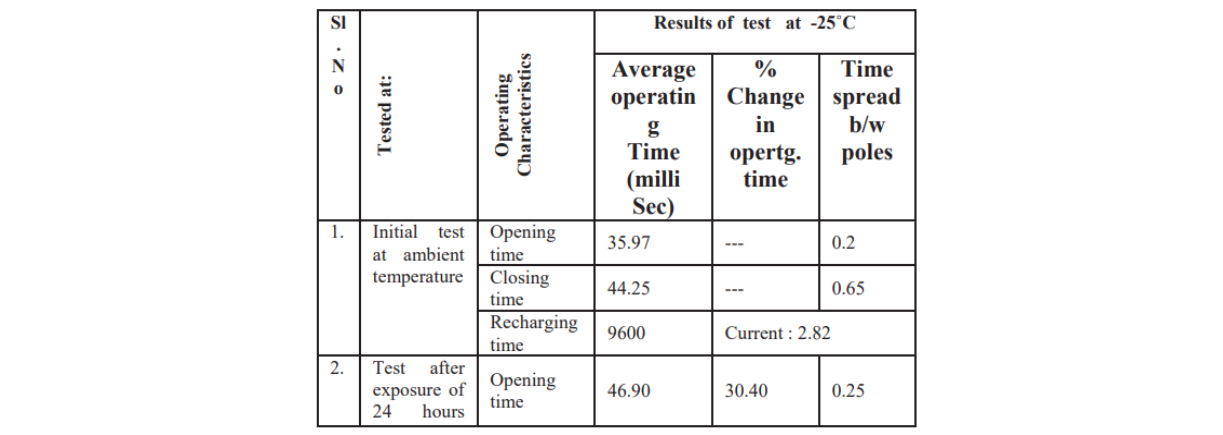

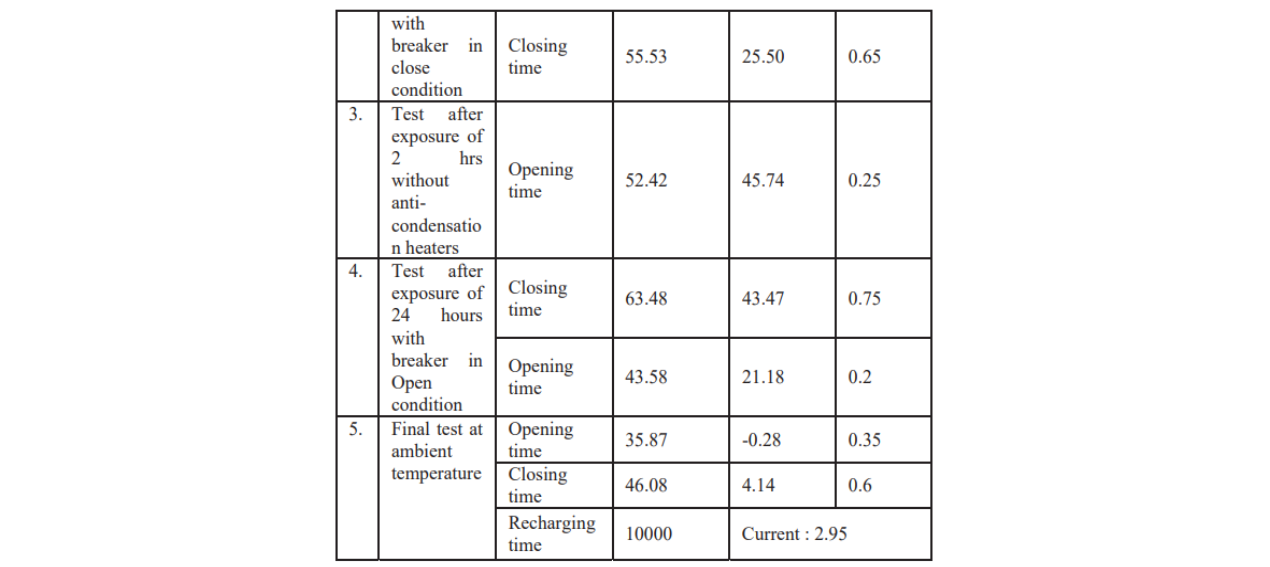

The results of the high - temperature test are presented in Table 1. Initial characteristics were measured at 20°C. IEC 62271 - 100 does not specify any value for operating time or closing time. The measured initial opening times are about 36 ms, and the closing time is around 44 ms. Similarly, the recharging time of the operating device ranges from 9.6 sec to 11.3 sec, and the recharging current is in the range of 2.8 A to 3.1 A.

After 24 hours of exposure to 55°C with the breaker in the closed position, the opening time and closing time uniformly increased by about 5%. After a further 24 - hour exposure to 55°C with the breaker in the open position, the closing time increased by about 2.5%, and the opening time increased by 4%.

There was no significant change in the time spread between poles for all three test samples during the entire test. Hence, it can be inferred that the behavior is similar in all the poles of the VCB.The recharging time decreased from 11.3 sec to 9.6 sec, but the current changed from 2.9 A to 3.4 A.

When comparing the opening and closing times between the initial and final values at ambient temperatures, a change of less than 1% in the operating time was observed, which is negligible.

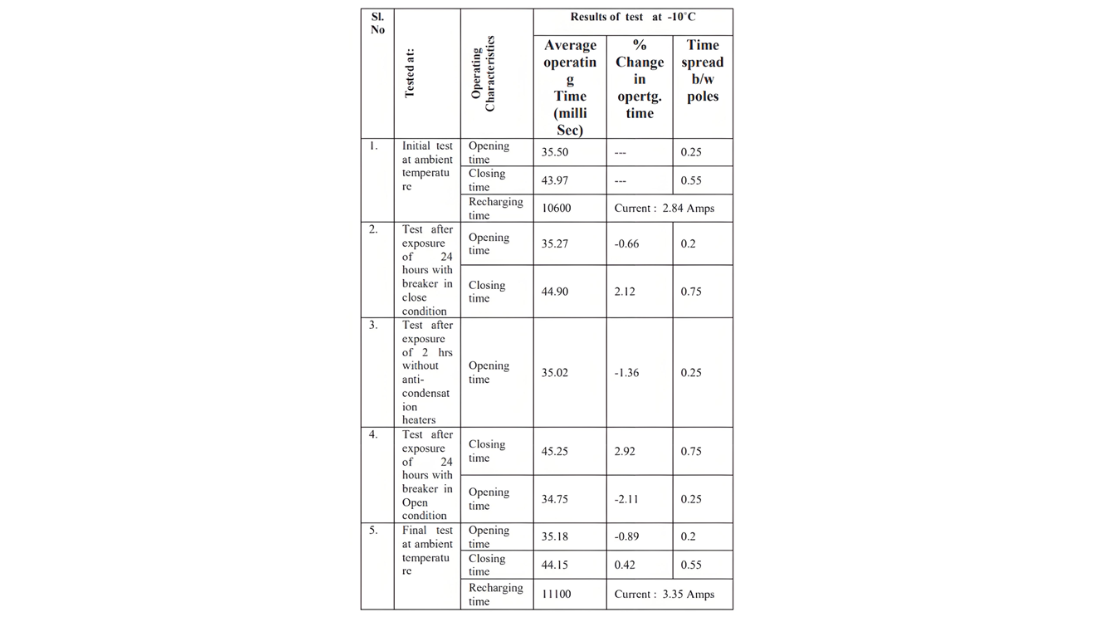

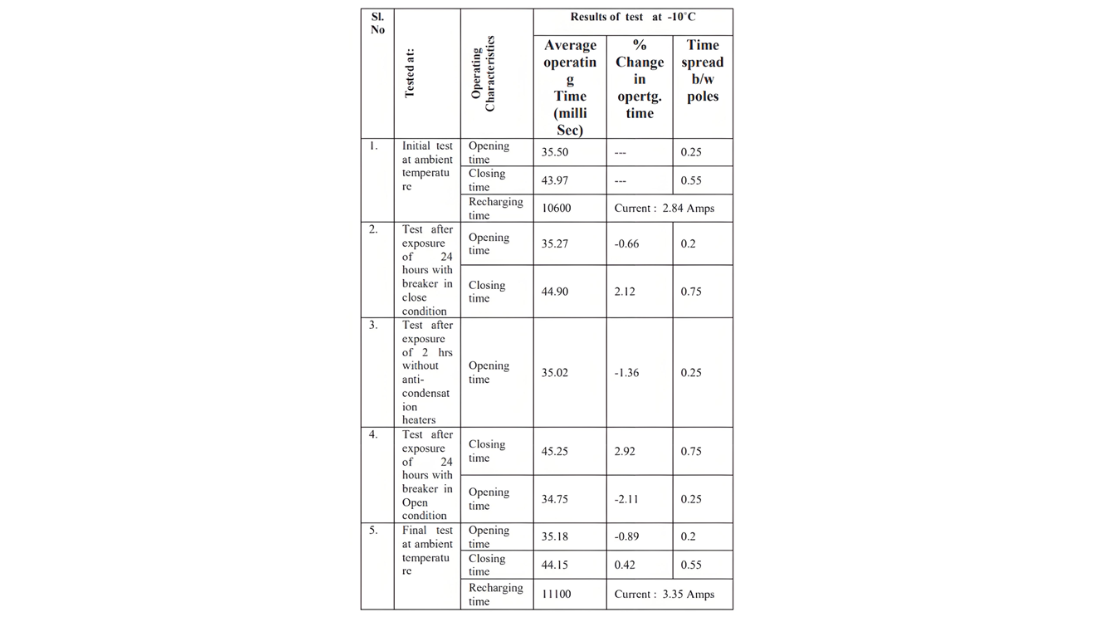

The initial operating characteristics were measured at 20°C. The measured initial values of the opening time were around 36 ms, and the closing time was 44 ms. Similarly, the recharging time of the operating device was 10.6 sec, and the recharging device current was 2.8 A.

After 24 hours of exposure to -10°C with the breaker in the closed position, the opening time decreased by about 0.7%, and the closing time increased by about 2%, with no significant change.

During the two - hour period without anti - condensation heaters, the opening time decreased by 1.36%.After a further 24 hours of exposure to -10°C with the breaker in the open position, the closing time increased by about 3%, and the opening time has decreased by about 2%.

During the final test at ambient temperature, the change was less than 1%. Throughout the entire low - temperature test period at -10°C, there was no significant change in the time spread between poles.

The performance of the breaker at various temperatures, starting from +55°C, -10°C, and -25°C, is presented in Table 1.

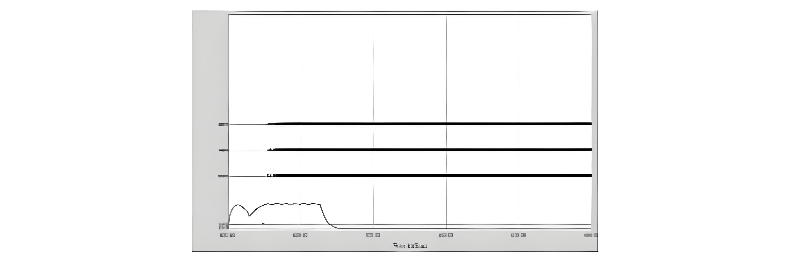

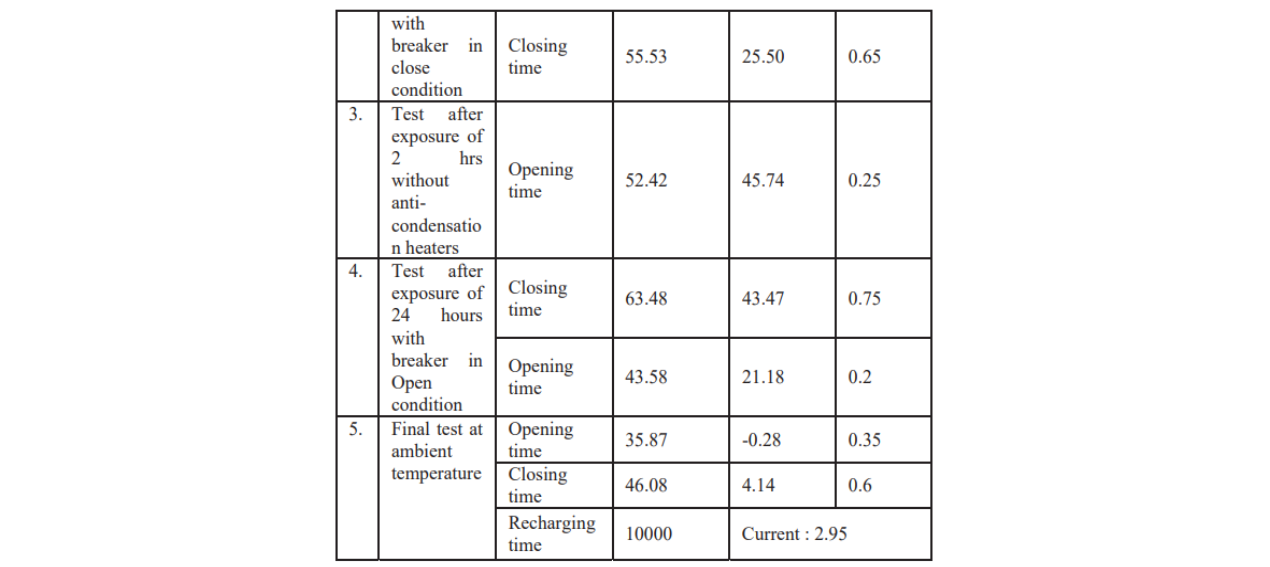

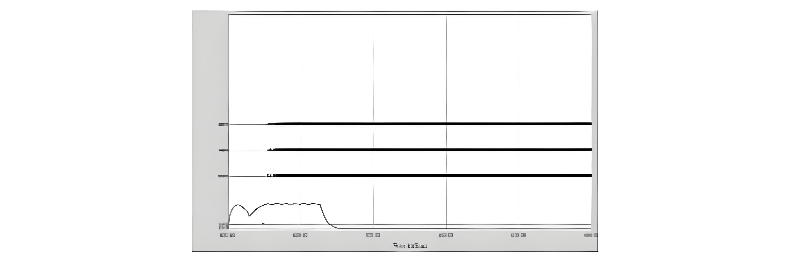

Significant changes in operating time were observed when the breaker operated at a low temperature of -25°C. The results in Table 3 indicate that the breaker exhibited sluggishness during opening and closing at -25°C. The percentage change in operating time at -25°C was notably different. After 24 hours of exposure, the opening time increased by 30%, and the closing time increased by approximately 25%. Similarly, after the anti - condensation heating elements were turned off for two hours, the opening time increased by 46%. Further exposure for 24 hours at -25°C with the breaker in the open position and the anti - condensation heating element supply restored led to a 44% increase in the opening time and a 21% increase in the closing time. The timing graphs for closing time and opening time recorded during the test clearly show these changes.

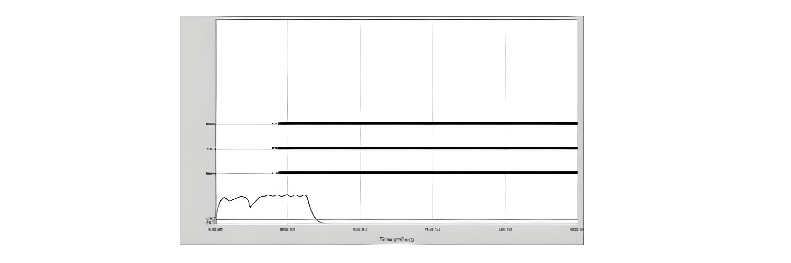

The test at an ambient temperature of 20°C is shown in Figure 2. The timing graphs of the closing time recorded after 50 hours of exposure at -25°C are provided in Figure 3. When compared, the sluggishness of the breaker at -25°C is clearly evident.

When compared with its performance at -10°C, where the change in operating time was only around 0.5% to 3%, the breaker's characteristics at -25°C have deteriorated significantly. At -25°C, the operating - time changes during various stages of the test reached approximately 45%.

This paper presents the experimental results of comparing the performance of 36 kV - class outdoor vacuum circuit breakers (VCBs) during low - and high - temperature tests in accordance with IEC 62271 - 100.

The key findings of this paper are as follows:

During the high - temperature test at 55°C, the outdoor VCBs performed satisfactorily. The observed changes in operating time and time spreads between poles were insignificant.

During the low - temperature test at -10°C, the changes in operating time and time spread between poles were insignificant.

Significant changes in operating time were observed when the breaker operated at a low temperature of -25°C. The observed changes in opening time ranged from 20% to 46%, and changes in closing time were in the range of 25% to 43%.

The tests conducted indicate that even if an outdoor VCB can operate normally at -10°C, there is no guarantee that it will perform the same in colder conditions such as -25°C. Thus, it is essential to verify its performance at the required low temperature.