Common faults of insulators and preventive measures

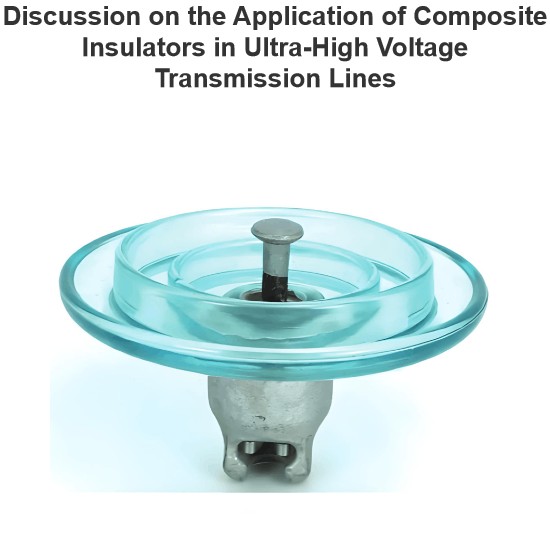

An insulator is a special type of insulating component that serves the dual purpose of supporting conductors and preventing current from grounding in overhead transmission lines. It is widely used at the connection points between transmission towers and conductors, as well as between substation structures and power lines. Based on the dielectric material, insulators are classified into three types: porcelain, glass, and composite. Analyzing common insulator faults and preventive maintenance measures is primarily aimed at preventing insulation failure caused by various mechanical and electrical stresses due to environmental and electrical load changes, thereby safeguarding the operation and service life of power lines.

Fault Analysis

Insulators are exposed to the atmosphere year-round and are susceptible to various accidents due to factors such as lightning strikes, pollution, bird damage, ice and snow, high temperatures, extreme cold, and elevation differences.

- Lightning Strike Accidents: Overhead line corridors often pass through hilly areas, mountains, open fields, and industrially polluted zones, making the lines highly vulnerable to lightning strikes, which can lead to insulator puncture or shattering.

- Bird Damage Accidents: Research shows that a significant portion of insulator flashovers are caused by birds. Compared to porcelain and glass insulators, composite insulators have a higher probability of flashover due to bird activity. Such incidents mostly occur on transmission lines of 110 kV and above, while flashovers due to bird damage are rare in 35 kV and lower urban distribution networks. This is because bird populations are relatively smaller in urban areas, line voltages are lower, the air gap that can be bridged is small, and insulators typically do not require corona rings; their shed structure effectively prevents bird-induced flashovers.

- Corona Ring Accidents: During operation, the electric field near the metal fittings at the ends of insulators is highly concentrated, with high field strength near the flange. To improve field distribution, corona rings are commonly installed on grids of 220 kV and above. However, corona rings reduce the effective air clearance of the insulator string, lowering its withstand voltage. Additionally, the low corona inception voltage at the corona ring's fixing bolts can lead to corona discharge under adverse weather conditions, affecting the safety of the insulator string.

- Pollution Accidents: These occur when conductive contaminants accumulated on the insulator surface become damp in humid weather, significantly reducing insulation performance and causing flashover under normal operating voltage.

- Accidents of Unknown Cause: Some insulator flashover incidents have undetermined causes, such as zero-value porcelain insulators, shattered glass insulators, or tripped composite insulators. Despite post-incident inspections by operating units, the exact cause of flashover often remains unidentified. These incidents commonly occur from late night to early morning, especially during rainy or overcast weather, and many can be successfully auto-reclosed.

Maintenance Measures

The main causes of lightning-induced flashover include insufficient dry-arc distance, single-end corona ring configuration, and excessive tower grounding resistance. Preventive measures include using extended-length composite insulators, installing double corona rings, and reducing tower grounding resistance.

To effectively prevent bird damage, operating units should install bird-spiking nets, bird needles, or bird guards in sections prone to frequent bird-related incidents.

For lines equipped with corona rings, an equal spacing design between large and small sheds should be adopted, with shed spacing meeting technical requirements. If not, the creepage distance of insulators should be increased to reduce flashover risks caused by ice and snow. Regular inspections and patrols should be strengthened, with periodic sampling of insulators operating in different regions and environments for tensile strength, electrical performance, and insulation aging tests to prevent flashovers due to insufficient mechanical strength or shed aging.

To prevent pollution flashovers, the following measures are generally adopted:

- Regular cleaning of insulators. A comprehensive cleaning should be conducted before the high-pollution flashover season, with increased frequency in heavily polluted areas.

- Increasing creepage distance and enhancing insulation level. This includes adding more insulator units in polluted areas or using anti-pollution insulators. Operational experience shows that anti-pollution insulators perform well in heavily polluted sections.

- Applying anti-pollution coatings, such as paraffin wax, petroleum jelly, or silicone organic coatings, to improve the insulator's surface pollution resistance.

- For flashover incidents of unknown cause, new insulators of the same model and old ones that have been in service for over three years should undergo power-frequency dry flashover and mechanical failure tests. Aging tests should also be conducted on insulators from different service periods. Insulators should be cleaned regularly according to scheduled cycles, and salt deposit density (SDD) should be measured promptly. During the production of new insulators, advanced anti-aging agents should be incorporated to enhance material durability.

Hey there! I'm an electrical engineer specializing in Failure and Maintenance. I've dedicated my career to ensuring the seamless operation of electrical systems. I excel at diagnosing complex electrical failures, from malfunctioning industrial motors to glitchy power distribution networks. Using state - of - the - art diagnostic tools and my in - depth knowledge, I pinpoint issues quickly. On this platform, I'm eager to share my insights, exchange ideas, and collaborate with fellow experts. Let's work together to enhance the reliability of electrical setups.