The Rise and Future of Intelligent Inspection Robots

I. The Rise of Intelligent Inspection Robots

In today’s rapidly advancing technological era, intelligent inspection robots are emerging as shining stars across various industries, revolutionizing traditional inspection practices.

Imagine the past: in large factories, inspectors had to walk long distances along complex production lines, manually checking equipment conditions. This was not only time-consuming and labor-intensive but also posed safety risks in harsh environments. Now, intelligent inspection robots have transformed this process.

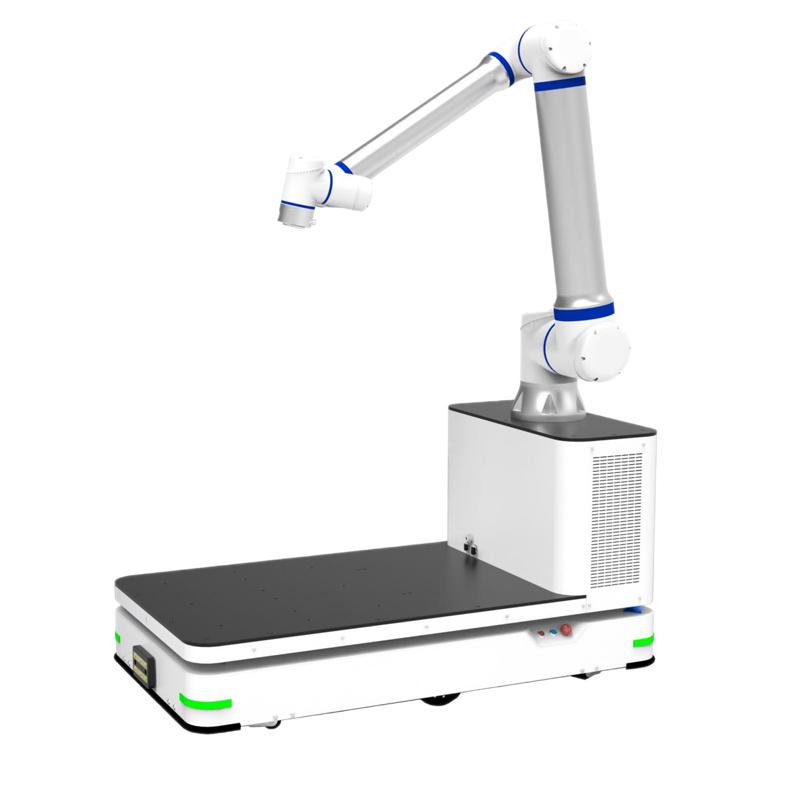

These robots tirelessly follow pre-programmed routes through factories, equipped with advanced sensors—acting as their "eyes" and "ears." Visual sensors clearly detect equipment damage or loose components, while acoustic sensors capture subtle abnormal sounds during operation, identifying potential failures early.

In power systems, where inspectors once climbed poles and traversed difficult terrain—especially hazardous in bad weather—inspection robots now smoothly travel along power lines. They thoroughly inspect towers, insulators, and conductors, walking freely on high-voltage transmission lines. They accurately monitor parameters like temperature and humidity, instantly reporting overheating or other issues to control centers for timely intervention, ensuring stable power supply.

In the oil and gas industry, where environments are often flammable and explosive, traditional inspections carry high risks. Intelligent robots excel here by entering hazardous zones to inspect pipelines and valves, eliminating direct human exposure and significantly improving both safety and efficiency.

II. Core Technologies Behind Intelligent Inspection Robots

The outstanding performance of these robots relies on several cutting-edge technologies.

First is navigation and positioning—the robot’s “GPS.” It enables precise movement along planned routes in complex environments. Common methods include laser and visual navigation. Laser navigation uses sensors to emit laser beams and calculates position based on reflection time, achieving bat-like precision. Visual navigation uses cameras to recognize landmarks or features, similar to how humans use maps.

Second is sensor technology. Beyond visual and acoustic sensors, robots use temperature sensors to monitor equipment heat (indicating internal faults) and pressure sensors to ensure safe pipeline conditions. These act as the robot’s “sensory organs,” continuously gathering environmental and equipment data.

Third is data analysis and processing. The vast amount of collected data must be analyzed to extract meaningful insights. Using big data analytics and machine learning, robots learn from historical data to build fault prediction models. When new data arrives, they compare it in real time, detect anomalies, and issue early warnings.

For example, in a large warehouse, an inspection robot uses laser navigation to move between shelves. Its visual sensors check for disorganized or damaged goods, while temperature sensors monitor ambient conditions. If it detects overheating in a zone, it instantly alerts the management system. The system analyzes the data, identifies a potential AC failure, and dispatches maintenance—preventing product damage.

III. Real-World Applications Across Industries

(A) Manufacturing

In an automobile factory, intelligent robots inspect complex production lines, including stamping machines, welding robots, and painting systems.

Visual sensors detect tiny cracks or wear on stamping molds, reporting issues immediately. For welding robots, they assess weld quality by analyzing appearance and strength. In painting, they verify coating thickness and uniformity, ensuring high-quality finishes.

Since deployment, equipment failure rates have dropped significantly. Production line stoppages due to faults have decreased, boosting efficiency. Predictive maintenance has also reduced repair costs. In one year, maintenance expenses dropped by about 20%, and productivity increased by 15%.

(B) Power Industry

A power company widely deploys inspection robots across its grid. These robots patrol high-voltage lines, monitoring real-time operational status.

During one inspection, a robot detected slight discharge on an insulator surface. It instantly transmitted the data to the control center. Engineers confirmed contamination as the cause and promptly cleaned or replaced the insulator, preventing further damage and ensuring grid stability.

Robots also inspect substations, checking transformer oil temperature and level, and circuit breaker status. Real-time monitoring and analysis help detect anomalies early, supporting reliable power delivery. Compared to manual inspections, robots improve accuracy, efficiency, and safety.

(C) Rail Industry

Along railway lines, inspection robots monitor tracks, bridges, and tunnels.

High-precision visual sensors detect rail wear or foreign objects. For bridges, they check for cracks in piers or deformation in steel beams. In tunnels, they monitor lining integrity for damage.

In one case, a robot detected a small stone on the track. If left, it could cause train instability or derailment. The robot reported it instantly, and maintenance crews quickly removed it, ensuring safety. With robots, rail operators detect hazards early, enhancing safety and reliability.

IV. Challenges and Solutions in Application

Despite their advantages, intelligent inspection robots face challenges.

Environmental Adaptability: Harsh conditions—high temperature, humidity, dust, or electromagnetic interference—can impair robot performance. For example, electronics may overheat in steel plants; dust can cover sensors outdoors.

Solutions: Develop robots with heat-resistant, waterproof, dustproof, and EMI-shielded hardware and software. Use better cooling materials, optimize thermal design, and add automatic sensor cleaning mechanisms.

Data Security and Privacy: Robots collect vast amounts of sensitive data, including proprietary and personal information. Data breaches could cause severe losses.

Solutions: Implement robust data security: encrypt data, restrict access to authorized personnel only, and strengthen network defenses against cyberattacks.

Human-Robot Collaboration: While robots handle most tasks, human intervention is still needed in complex scenarios. Efficient collaboration is key.

Solutions: Develop intuitive human-machine interfaces and communication systems. Use mobile apps or terminals to deliver real-time robot alerts. Enable two-way interaction so operators can guide robots or respond to issues effectively.

V. Future Trends of Intelligent Inspection Robots

Looking ahead, inspection robots will become smarter, more multifunctional, and smaller.

Smarter AI: Robots will gain stronger autonomous decision-making. Using adaptive algorithms, they’ll assess fault severity and prioritize responses—deciding whether to alert humans or perform basic emergency actions.

Multifunctionality: Beyond inspection, robots will integrate cleaning and maintenance. In cleanrooms or electronics plants, they can clean surfaces and lubricate parts during patrols, enabling “one robot, multiple roles” and boosting maintenance efficiency.

Miniaturization: Smaller robots will access tight spaces—like inside precision instruments or electronic devices—performing detailed inspections of tiny components and circuits.

Advanced Connectivity: With 5G and IoT, robots will transmit data faster and more reliably. They can form collaborative networks, covering large areas like industrial parks with coordinated patrols.

Integration with VR/AR: Combined with virtual and augmented reality, robots will enable remote expert guidance. Technicians can view robot-collected data in immersive formats, improving diagnosis and repair efficiency.

Ⅵ.Conclusion

Intelligent inspection robots are transforming industrial maintenance, enhancing safety, efficiency, and reliability. As technology advances, their role will expand, paving the way for smarter, more resilient industrial operations.