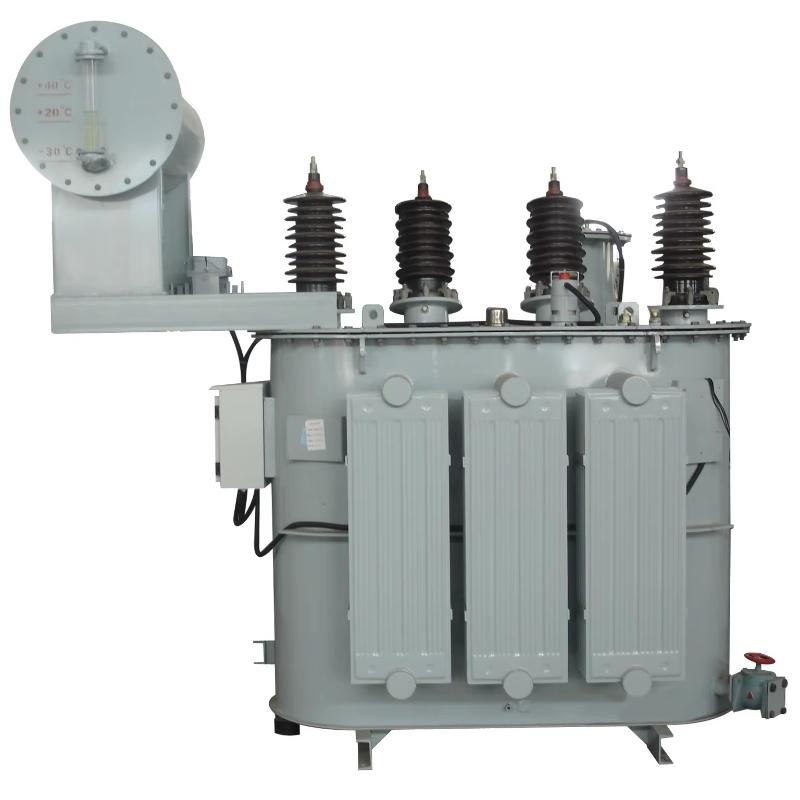

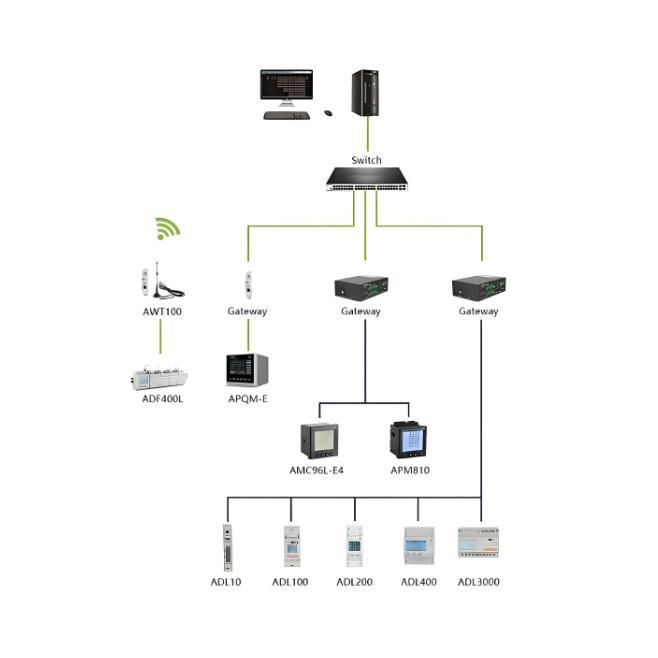

- Product

- Suppliers

- Manufacturers

- Solutions

- Free tools

- Knowledges

- Experts

- Communities

Search

-

Ferramentas gratuitas

-

IEE Business ofrece ferramentas gratuítas impulsadas por IA para o deseño en enxeñaría eléctrica e a planificación de presupostos de compra de enerxía: introduce os teus parámetros, fai clic en calcular e obtén resultados instantáneos para transformadores, cableado, motores, custos de equipos eléctricos e máis — confiado por enxeñeiros de todo o mundo.

-

-

Soporte e Patrocinio

-

IEE-Business apoia soluciós líderes empresas e expertos creando unha plataforma onde a innovación se encontra co valorCoñecementos técnicos excelentesÚnete e comparte coñecementos técnicos para gañar diñeiro de patrocinadoresSolucións Empresariais ExcelentesUnirse e crear solucións comerciais para gañar diñeiro de patrocinadoresExpertos Individuais DestacadosMostra o teu talento aos patrocinadores gaña o teu futuro

-

-

Descargar a aplicación

Descargar

-

-

Obter a aplicación comercial IEE-BusinessUsa a aplicación IEE-Business para atopar equipos obter soluções conectar con expertos e participar na colaboración da industria en calquera momento e lugar apoiando completamente o desenvolvemento dos teus proxectos e negocio de enerxía

-

-

-

-

Colabora con nós

Socio

-

-

Unirse ao programa IEE Business PartnerImpulsando o crecemento empresarial -- Desde ferramentas técnicas ata a expansión global

-

-

-

Galego

-

- English

- Afrikaans

- العربية

- Azərbaycan dili

- български

- বাংলা

- Català

- Cebuano

- čeština

- Dansk

- Deutsch

- Ελληνικά

- Esperanto

- Español

- Eesti keel

- Euskara

- دری

- فارسی

- suomi

- Filipino

- français

- Gaeilge

- Galego

- Hausa

- עברית

- हिन्दी

- Hrvatski

- magyar nyelv

- հայերեն

- Bahasa Indonesia

- Íslenska

- Italiano

- 日本語

- ქართული

- Қазақ тілі

- ಕನ್ನಡ

- 한국어

- Kurdî

- Latina

- Latviešu valoda

- македонски јазик

- Bahasa Melayu

- Malti

- नेपाली

- Nederlands

- Norsk

- ਪੰਜਾਬੀ

- polski

- پښتو

- Português

- Русский язык

- සිංහල

- Slovenščina

- српски језик

- Svenska

- Kiswahili

- தமிழ்

- తెలుగు

- ไทย

- Tagalog

- Türkçe

- українська мова

- اردو

- Oʻzbek tili

- Tiếng Việt

-

Coñecementos técnicos excelentes

Solucións Empresariais Excelentes

-

Galego

-

- English

- Afrikaans

- العربية

- Azərbaycan dili

- български

- বাংলা

- Català

- Cebuano

- čeština

- Dansk

- Deutsch

- Ελληνικά

- Esperanto

- Español

- Eesti keel

- Euskara

- دری

- فارسی

- suomi

- Filipino

- français

- Gaeilge

- Galego

- Hausa

- עברית

- हिन्दी

- Hrvatski

- magyar nyelv

- հայերեն

- Bahasa Indonesia

- Íslenska

- Italiano

- 日本語

- ქართული

- Қазақ тілі

- ಕನ್ನಡ

- 한국어

- Kurdî

- Latina

- Latviešu valoda

- македонски јазик

- Bahasa Melayu

- Malti

- नेपाली

- Nederlands

- Norsk

- ਪੰਜਾਬੀ

- polski

- پښتو

- Português

- Русский язык

- සිංහල

- Slovenščina

- српски језик

- Svenska

- Kiswahili

- தமிழ்

- తెలుగు

- ไทย

- Tagalog

- Türkçe

- українська мова

- اردو

- Oʻzbek tili

- Tiếng Việt

-

Calculadoras eléctricas gratuítas

Coñecementos técnicos excelentes

Solucións Empresariais Excelentes