Circuitus interruptores SF₆ habent excellentes proprietates physicas, chemicas, insulationis et extinctionis arcus. Permittunt magnam numerum interruptionum consecutivorum, habent parvum sonitum, et nullum periculum scintillationis. Praeterea, sunt parvi in magnitudine, leves in pondere, magni in capacitatis, et exiguae vel nulla est necessitas maintenance. Propter haec, paulatim substituunt circuitus interruptores traditionales oleosi et aere compresso. Porro, in distributione mediae potentiae, hii circuitus interruptores habent praestantias ut non reaccendantur quando interrompuntur currentes capacitates et non generent over-voltage quando interrompuntur currentes inductivi, quod ad usum eius latum duxit.

1 Proprietates Gas SF₆

1.1 Proprietates Physicae

Pondera molecularia gas SF₆ est 146.07, et diametri molecularis est 4.56×10⁻¹⁰ m. Sub temperaturis et pressionibus normalibus existit in statu gaseoso. Ad 20°C et una pressione atmospherica, densitas eius est 6.16 g/L (circa quinque vices aeris). Temperatura critica gas SF₆ est 45.6°C, et potest liquefieri per compressionem. Saepe transportatur in cylindris ferreis in statu liquido. Pura SF₆ gas est sine colore, sine odore, sine sapore, non venenosa, et non inflammabilis.

1.2 Proprietates Electricae

(1) SF₆ est gas electronegativum (capax adsorbendi electrona libera), cum excellentibus proprietatibus extinctionis arcus et isolationis. In campo electrico uniformi sub una pressione atmospherica, fortitudo voltage-resistens gas SF₆ est circa 2.5 vices nitrogeni.

(2) Pura SF₆ gas est gas inertis. Decomponitur sub actione arcus. Quando temperatura superat 4000K, plures producti decompositionis sunt atomi singulares sulfuris et fluoris. Postquam arcus extinguetur, vasta pars productorum decompositionis recombiniunt in stabiles moleculas SF₆. Inter eos, minimus quantitas productorum decompositionis reagunt chimice cum atomis metallicis liberis, aqua, et oxyge no durante processu recombinationis, generantes fluorides metallicos et fluorides oxydis et sulfuris.

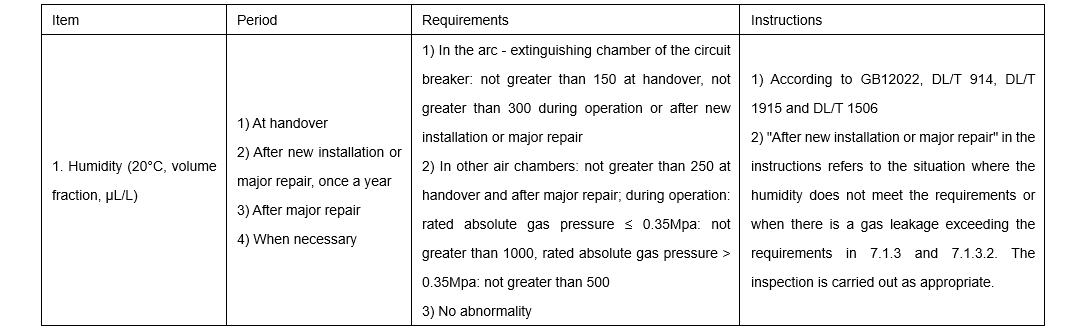

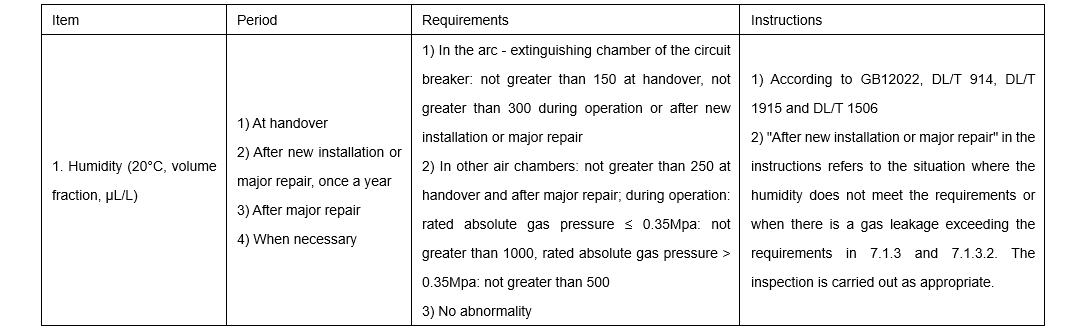

2 Test Micro-aquae Gas Circuitus Interruptoris SF₆

2.1 Significatio Test Micro-aquae

Detectio contentus micro-aquae in gas est major test item pro circuitus interruptoribus SF₆. Novum SF₆ gas vel gas in operatione continens vestigia aquae directe afficiet proprietates gas. Quando contentus aquae attingit certum gradum, reactiones hydrolysis facile occurrunt, generantes substantias acidas quae possunt corrodere apparatus. Praesertim sub altis temperaturis et actione arcus, facile generantur toxicis fluorides. Producta fluorosulfurica reagunt cum aqua formando acidum hydrofluoricum, sulfuricum, et alios toxicissimos chemicos, periculosos vitae personarum maintenance et corrosivos materialibus insulatoribus vel metallis circuitus interruptoris, causantes degradatio insulationis. Quando circuitus interruptor installatur foris et temperatura acute descendit, excessiva aqua in gas SF₆ posset condensari in superficie medium solidi, ducens ad flashover. In casibus gravioribus, posset facere circuitus interruptor explodere.

2.2 Methodi Testing

(1) Gravimetrica: Postquam transierit per desiccans, mutatio ponderis eius accurate mensuratur. Tamen, haec methodus habet alta requisita operationis et consumit magnam quantitatem gas in constante-temperatura, constante-humiditate, et sine-pulvere environment.

(2) Dew-point method: Quando temperatura systematis test est leviter minus quam temperatura saturatio vaporis aquae (dew point) in sample gas, systema test potest dare signale electricum. Post amplificationem et output, contentus aquae determinatur ex valore dew-point. Hoc tempore, haec methodus est importantis modus mensurandi vestigia aquae in SF₆, et dew-point meters producuntur tam domi quam foris.

3 Fontes et Control Humiditatis in Gas Circuitus Interruptoris SF₆

3.1 Fontes Humiditatis in Gas

(1) Pro novo gas, principes fontes humiditatis sunt: detectio insuficiente stricta ab plantis fabricantium gas; non-compliant storage environments durante transportatione; et tempus storage excessivum.

(2) Pro apparatu electrico repleto SF₆ gas, principes fontes humiditatis sunt: humiditas adducta ab ipso SF₆ gas; vestigia humiditatis propter purificationem incompletam gas ante charging; humiditas gradualiter emissa per tempus a materialibus insulatoribus, partibus weldata, et componentibus in apparatu electrico; et humiditas quae intrat ab extra per leakage equipment.

3.2 Misure Control pro Contentu Aquae SF₆ Gas in Circuitus Interruptoribus SF₆

Sicure inspectionem qualitatis strictam durante acceptatione novi gas; control treatment of insulating parts; control quality of sealing parts; control quality of adsorbents; control operation during gas charging; strengthen gas leakage detection during operation; and strengthen the monitoring and measurement of gas micro-water during operation.

4 Toxicitas Gas SF₆

Quando SF₆ gas utitur in apparatu electrico, sive sub conditionibus defectus sive durante normali interruptione arcus, posset decomponi ad generandum fluorides oxygenis et sulfuris, sicut et pulveres fluoridi metallici. Quando contentus fluorides hydrolysabiles in gas SF₆ attingit certam concentrationem, SF₆ gas fit toxicus, et etiam afficit fortitudinem insulationis et performance extinctionis arcus SF₆ gas in apparatu electrico.

Sub actione spark discharge et arc, circuitus interruptores SF₆ gas generabunt gases toxicissimos per dissociationem et ionizationem. Quia haec gases sunt sine colore et sine odore, difficilis sunt ad detectio. Praeterea, cum densitate 6.16 g/L (circa quinque vices aeris), aliquot toxicas et nocivas gases generatae durante monitoring accumulantur iuxta terram in camera switch. Hoc facit facilem potential poisoning of workers durante disassembly, major repairs, or micro-water testing of the gas, posing a great threat to the physical and mental health of workers and the safe operation of equipment.

Exempli gratia, si SF₆ gas leakage monitoring and alarm system and a quantitative SF₆ gas leakage detector non instalaruntur in SF₆ switch room, impossibile est scire utrum SF₆ concentration sit intra range standardis safe. Experientia demonstrat quod etiam in environment cum vestigiis productorum decompositionis, operarii possunt sentire gases pungentes vel inconvenientes, quae possunt causare irritationem manifestam naso, ore, et oculis. Generaliter, post poisoning, symptomas sicut lacrimae, sternutationes, rhinus, sensus combustionis in cavitate nasali et pharyngi, vox raucida, tussis, vertigo, nausea, angustia pectoris, et inconvenientia in collum possunt occurrere. In casibus gravioribus, shock evenire potest.

Proinde, online monitoring of SF₆ gas leakage facta est major topic in current technical research. Exempli gratia, exhaust fan can be organically controlled together with the SF₆ gas leakage alarm system, so that the exhaust fan can be automatically turned on when the SF₆ gas leakage concentration exceeds the standard, ensuring the safety of personnel and equipment.

The two most important monitoring items for SF₆ circuit breakers are water content and leakage detection. If their reliability is affected, it will also pollute the environment. Therefore, the monitoring of micro-water and leakage detection of SF₆ circuit breakers in operation have received much attention.

(3) Electrolysis method: It can measure the humidity in the gas intermittently or continuously. There are other methods for micro-water testing of SF₆ gas, such as the piezoelectric quartz oscillation method, adsorption calorimetry, and gas chromatography. However, due to the high cost of the instruments or technical limitations, they have not been widely promoted and applied.