Paşan, çavkaniyê şeriyên xebitandinê wekî şeqla bêtir bikin, hewceyên herêmî yên ji bo serkeftin da li ser asta bike, pêşketina cihazê ya hewlemariyê bi rêjiyê wergerîn, wergeriya fikrê yê destpêkê yên jimanîn, kêrkirina guhertoya hewlemar û wan teknolojîya nû yên modern, destekîna yekbûyek da ku amadekirina cihanên taybetmend ên hewlêr da, û serkeftina şeriyên xebitandinê li ser asta yên projeksiyon û asta yên xebitandin, Şerketa Elektrîkî ya Nîvendî ya Çîna destpêk kirin da ku projeksiyon û xebitandina elektrastîn di rêjeya standardî de bike.

Yek ji objektîfên serekan da ku parametreyên û standartên dergeha cihazan bi rêjiyê wergerînin, ku cihazên yekemîn bi cihazên duyemîn û cihazên duyemîn yek bir bi rêjiyê wergerîn. Ev piştgirî dike ku kablên duyemîn bi rêjiyê wergerîn bixin, ku hizmetên zaf û rast bide ji bo karên wekî anbardan, operasyon û mirakirina cihazan, û daqaqên xebitandin ên proje yan dikare. Li ser vê bingehî, li ser elektrastînên akliyê, li gorî kablên prefabricated optical-electrical hybrid cables, dibeşkarên qeyser û analîz dike ku pir amariyek were ya şeqla niha.

1. Analîza Dêwehatiyan û Karûbarên Kablên Prefabricated Optical-Electrical Hybrid Cables

Li dema modern, şeqla kablê yên terminal yên panelên switchboard û fiber optic distribution boxes di ser elektrastînên da, di dema girîngkirinê de, ne lê zorîn ku barêyên nû yên elektrastînên prefabricated li ser asta bike. Di dema xebitandinê de, dema girîngkirina kablên û fiber optic cable yên di navên cabinetên de, girîngkirina circuit û debugkirina circuit, dema xebitandinê ya proje zêde ye.

Ev nîvêda ku serkeftina xebitandinê ya kam û gumanîya kam, û daqaqên binnavkirina, girîngkirina û şeqla cihazan di navên har cabinetê de. Buna, karên tekmîl û teknolojiya procesan di dema xebitandinê de zor e, ku beşek îstiçrakî da di dema mirakirinê de, û serkeftina kam di dema xebitandin û mirakirinê de.

Li ser vê bingehî, li gorî kablên prefabricated optical-electrical hybrid cables, ku avantajên plug-and-play-a çêd, omurê meh, sînora kecil, û gumanîya zêde, dike ku bêtir li ser barêyên nû yên cihazan li ser elektrastînên akliyê bide.

Dibeşkar û Analîz li Ser Karrûbarên Kablên Prefabricated Optical-Electrical Hybrid Cables li Ser Elektrastînên Akliyê

Bijî, kablên prefabricated li ser posiyonên navên cihazan yekemîn GIS (Geographic Information System) û intelligent control cabinets. Ji bo elektrastînên akliyê ku bi cihazan GIS (Geographic Information System) re bikin, kablên prefabricated double-ended dibe ji bo girîngkirina circuit breaker û intelligent control cabinets, disconnectors û intelligent control cabinets, mechanism boxes û intelligent control cabinets, û main transformer terminal boxes û intelligent control cabinets.

Li ser şeqla girîngkirina navên, connector aviation plug dibe ji bo girîngkirin, û socket matching prefabricated bi navên. Dema li ser pergalên dual-loop circuits, strong and weak currents, AC û DC currents, configurationê raşt dibe.Pas li ser karûbarên kablên prefabricated, proces level componentên di cihazan de zêde bike. Ev nîvêda ku space di navên switchboard de hilîne, û girîngkirina li ser dema xebitandinê bêtir bikin.

Ji bo girîngkirina cihazan intelligent control cabinet bi cihazan bay-level, optical cables bikin. Lê, prosesê girîngkirina kablên normal optical zor e, û şertên environment ên fiber optic fusion splicing zor e. Buna, kablên prefabricated optical cables bi connector prefabricated factory dibe. Di dema xebitandinê de, connection method ên fusion-free bikin, ku optical attenuation û loss ên fiber optic fusion points minîmal bikin, û gumanîya û stabilitیتی fiber optic loop zêde bike.

2. Analîza Karakteristikên Teknîkî yên Kablên Prefabricated Optical-Electrical Hybrid Cables

Kablên optical-electrical hybrid cables ku conductors insulated di structure yên optical cables de hatine, power transmission copper wires û optical fibers di yek câre. Ji ber ku power transmission û optical cable transmission du rêjeyên transmission ûn mîna, interference di navên transmission de nekin. Kablên optical-electrical hybrid cables divê şeqla kablên optical û standard û specificationên low-voltage power transmission bikin, û hallek problemên transmission optical û electrical signals ûn cihazan.

Li ser avantajên kablên optical-electrical hybrid cables, ev karakteristikên sînora kecil, sînora kecil, û outer diameter kecil. Di demên paşan de, problemên ku bi kablên û kablên optical re hate hallek, niha bi yek kable hybrid hallek bike. Buna, karûbarên kablên optical-electrical hybrid cables avantajên din:

Di dema transmission de, transmission technologies yên jîn different types bike. Cihaz expandability û adaptability yên bêtir, û product coverage ên wide.

Li ser performansa karûbar, internal pressure resistance û bendability yên bêtir, û construction ên convenience.

Customers cost ên procurement ên zêde, û cost ên construction ên zêde.

Ji ber ku kable hybrid prefabricated e, di dema design stage de, hesabkirina û prediction ên actual laying length ên prefabricated optical cable raşt bike, ku standard û exceeds standard ên length minîmal bike. Niha, manufacturers cihazan kablên prefabricated optical-electrical hybrid cables bikin. Core count ên optical cable customization range 6 to 48 cores, û multimode û single mode dibe. Armors mostly copper û corrugated aluminum. Length prefabricated bikin, û connectors electrical û optical connectors bike.

Ji bo selection ên distribution frame, modular optical-electrical hybrid distribution frame bikin, ku ratio ên optical fibers û copper flexibly û scientifically configuration bikin, û satisfaction ên requirements ên power distribution management process.

Li ser karakteristikên kablên optical-electrical hybrid cables, di elektrastînên akliyê de, intelligent terminals ên bay ûn power loss alarm signals û unit optical signals uniform combined bikin, û transmission to bay protection, measurement, û control equipment bi same type ên optical-electrical hybrid cable. Ji bo AC û DC power supplies, wiring ên connecting equipment across floors û sites uniform simplified bikin, û idea ên all control signals ên typical bay connected bi one cable.

3. Analîz Case-Specific li Ser Karrûbarên Kablên Prefabricated Optical-Electrical Hybrid Cables

Vê makale case-specific li ser 110 kV û 220 kV sides ên elektrastînên akliyê. Bi comparing specific situations ên kablên prefabricated optical-electrical hybrid cables, main characteristics ên application ên kablên prefabricated optical-electrical hybrid cables elaborates:

(1) Statistical Analysis of the Specifications and Quantities of Optical-Electrical Hybrid Cables on the 110 kV Side

Based on the double-busbar wiring mode on the 110 kV side and the use of GIS equipment for research, there is a single-set configuration in the integrated device of the intelligent terminal merging unit for the 110 kV power line and the sectionalization; there is a double-set configuration in the integrated device of the intelligent terminal merging unit for the 110 kV main transformer incoming line. Two bus voltage merging units are installed in the intelligent control positions of the busbar equipment.

The following mainly takes the 110 kV line bay as an example. By centrally analyzing the quantities of optical cables and cables between the intelligent control cabinet and the secondary equipment, the specifications and quantities of the optical-electrical hybrid cables on the 110 kV side are sorted out and analyzed.

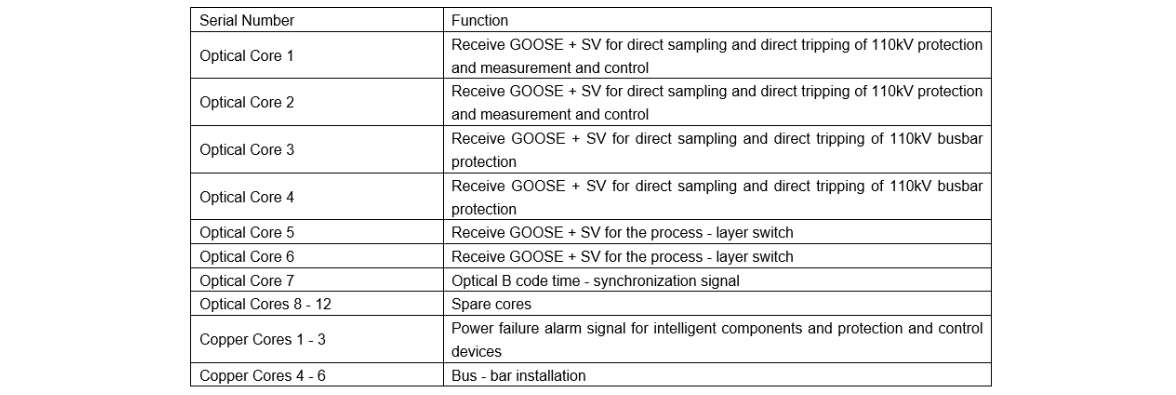

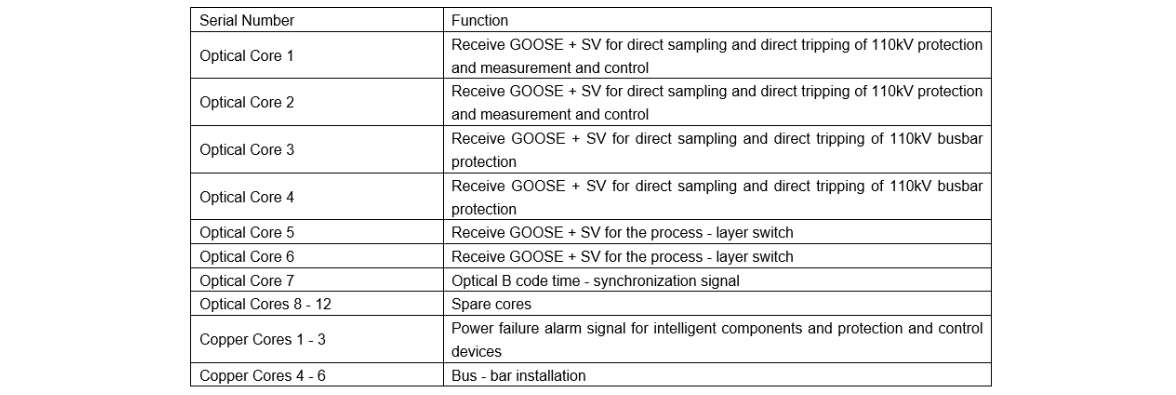

Table 1 Statistics of cable and optical cable coefficients in 110-kilovolt line intervals

As shown in Table 1, by centrally counting the number of optical fiber cores and cable cores from the process layer to the bay layer in the 110 kV line bay, and comprehensively considering the maximum demand and actual spare cores, a prefabricated optical - electrical hybrid cable composed of one 12 - core optical fiber plus 6×1.5 - sized copper wires is selected for the outgoing line and sectionalization bays. According to the dual - configuration of the main substation, two prefabricated optical - electrical hybrid cables, each composed of 12 - core optical fibers plus 6×1.5 - sized copper wires, are selected for the main intelligent control cabinet on the 110 kV side.

(2) Statistical Analysis of the Specifications and Quantities of Optical - Electrical Hybrid Cables on the 220 kV Side

Based on the double - busbar wiring mode on the 220 kV side and the use of GIS (Geographic Information System) equipment, the intelligent terminals and merging units are uniformly arranged in the intelligent control cabinet. The research on the configuration of the process layer and the bay layer is carried out using a dual - configuration method.

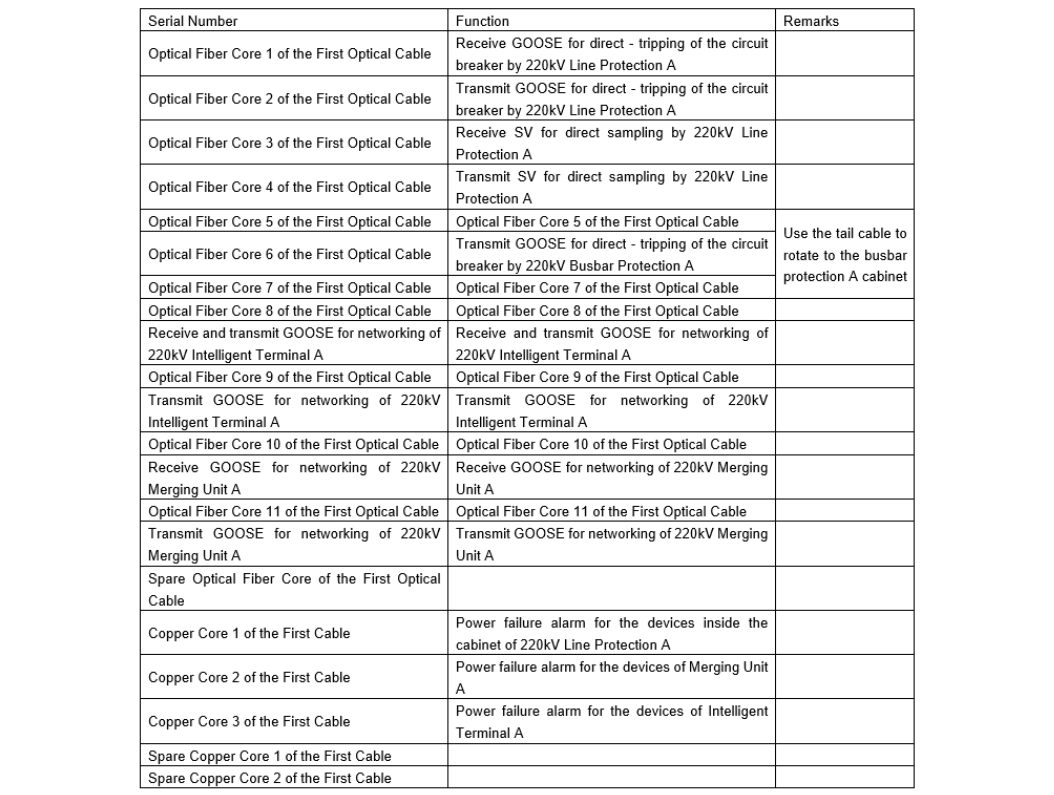

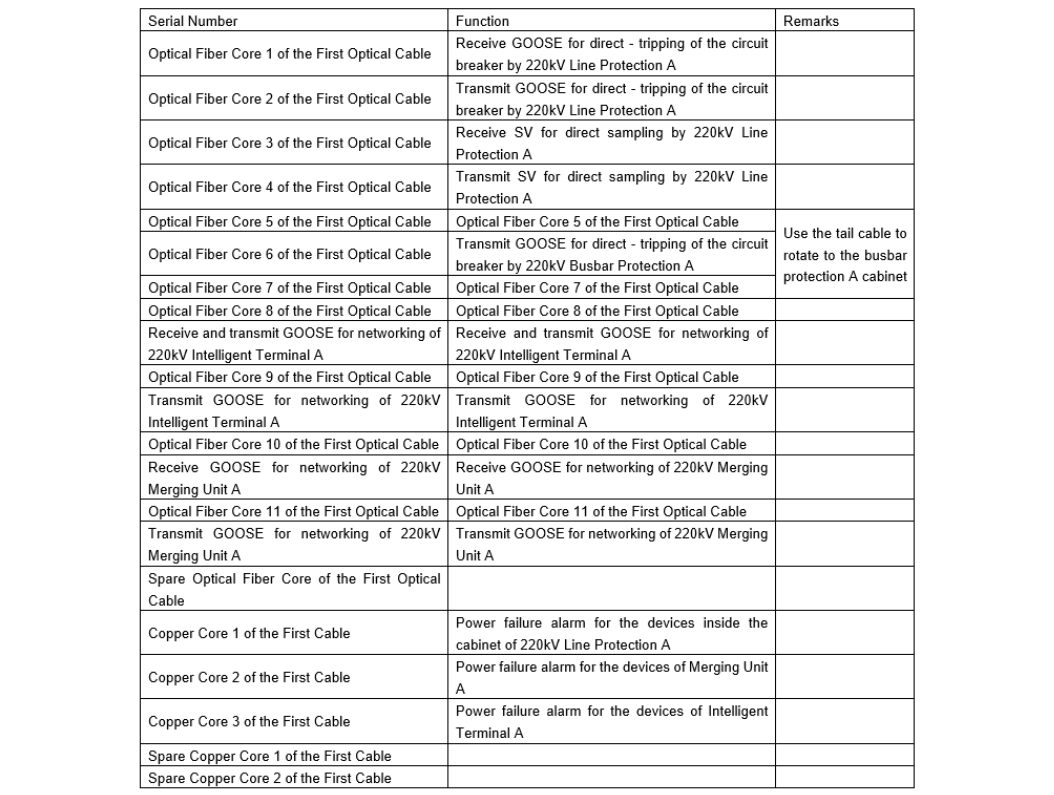

The following mainly takes the 220 kV line bay as a specific example. By statistically analyzing the quantities of optical cables and cables from the intelligent control cabinet to the secondary equipment room, the actual specifications and quantities of the 220 kV optical - electrical hybrid cables are sorted out and summarized.

Considering the dual - configuration on the 220 kV side, the number of cable cores and optical fiber cores of the second cable and its configuration are the same as those of the first cable. The specific content is shown in Table 2. By statistically analyzing the number of cable cores and optical fiber cores from the process layer to the bay layer in the 220 kV line bay, and systematically considering the maximum demand and spare cores, each intelligent control cabinet can use two prefabricated optical - electrical hybrid cables with a specification of 24 - core optical fibers plus 6×1.5 copper wires .

(3) Data Aggregation and Analysis of the Application of Optical - Electrical Hybrid Cables in Intelligent Substations

Based on the data from the above - mentioned statistical process, the analysis shows that in terms of specifications, the prefabricated optical - electrical hybrid cables used inside intelligent substations can be optimized into 24 - core optical cables + 6 - core cables and 12 - core optical cables + 6 - core cables.

The number of cables from the intelligent control cabinets on each side of the 220 kV and main substations to the secondary equipment room can be minimized to two, and the number of cables from the intelligent control cabinet on the 110 kV side to the secondary equipment room can be minimized to one.

As the cost of equipment materials in the investment process continues to decrease, a series of indirect economic benefits are generated, as follows:

The process - oriented and streamlined levels of cable component assembly are higher, and the work efficiency in the construction process is higher. This can maximize the savings in labor and engineering time and reduce the cost of on - site installation and construction.

After using prefabricated cables, it can specifically improve the standardization level of users, reduce the variety and quantity of materials, reasonably release the occupancy of the original inventory of users, and reduce the cost of management.

It reduces the workload in the later operation and maintenance process, has better green and environmental protection performance, and is more in line with the overall requirements of the construction of "two - type and one - standardization" substations.

Table 2 Statistics of Cable Cores and optical cable Cores in 220-kilovolt line intervals

4. Conclusion

In summary, the application of prefabricated cables in intelligent substations aims to achieve standardized and regulated connections for optical cables and cables between primary and secondary equipment, as well as among secondary equipment. This can specifically enhance the construction efficiency and process quality of secondary equipment during the construction phase.

This article has mainly discussed the application scope and technical characteristics of prefabricated optical - electrical hybrid cables. It has studied and analyzed the specific application of optical - electrical hybrid cables in 220 kV intelligent substations, and summarized and analyzed several common standard interfaces of hybrid cables used in 220 kV substations.

The use of prefabricated optical - electrical hybrid cables can organically integrate cables and optical cables. It can specifically reduce the laying workload at the construction site, decrease the cross - sectional size of cable trenches and the actual occupied area, and effectively cut down the project cost throughout the entire project cycle of intelligent substations.

The research content in this article mainly focuses on how to use optical-electrical hybrid cables to replace prefabricated optical cables for connecting secondary equipment between switchboards across different sites and in areas such as across rooms .