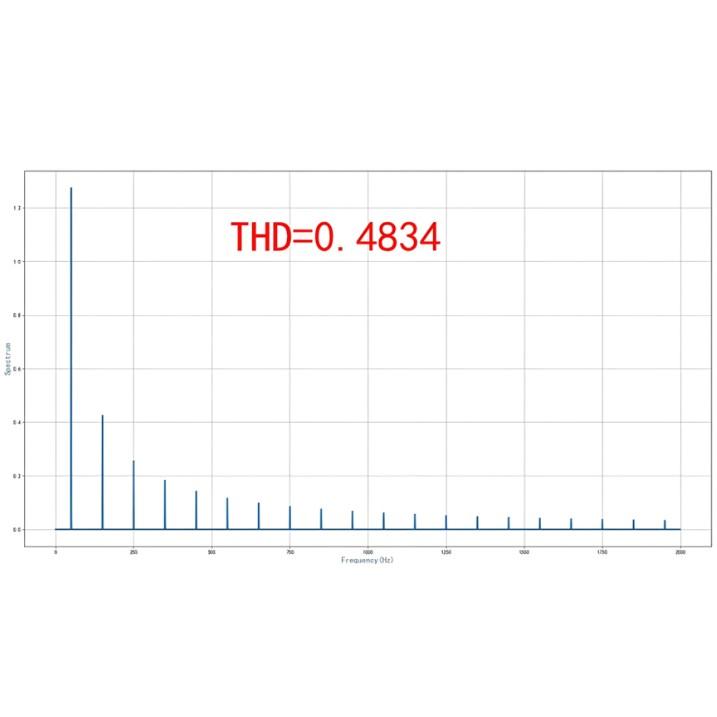

Nuair a mheastar gur mhór níos mó ná na teorainneacha (mar shampla, THDv Voltaige > 5%, THDi Cúrra > 10%), cuireann sé dianchar scíth go heorgánach ar tháirgeadh ar fud an bhéim ghineadóireachta uile — Trasnáil → Díol → Gineadh → Rialú → Úsáid. Is iad na meicnísmí bhuíoch agus foréigneach a chuirtear isteach, corraíocht ar mhóinín, agus fuaimniú éagsúla.

1. Táirgeadh Trasnála: Teaspachadh, Seanós, agus Saol Mhíleata Go Forleathan

Is é an t-equipment trasnála a dhéanann an cúrra/voltaige gréasáin a chur go díreach. Cuireann na harmónaigh le haistear agus leis an ndiúltú insil. Is iad na príomhchuidiú a bhfuil tionchar orthu ná línte trasnála (cábail/línte os cionn talún) agus transformaitheoirí cúrra (CTs).

1.1 Línte Trasnála (Cábail / Línte Os Cionn Talún)

Meicnísmí Damáiste: Téann na fréimeacha harmónacha ard in aghaidh an "skin effect" (concentrates the high-frequency currents on the surface of the conductor, reducing the effective cross-sectional area), ag méadaú an tiomáin líne. Méadaíonn na copper losses ar an ord harmónach (mar shampla, is 25× an loss 5th harmonic ná an bunord).

Damáiste Speisific:

Teaspachadh: Ag THDi = 10%, méadaíonn na copper losses ar feadh 20%-30% i gcomparáid leis an rátáil. D'fhéadfadh teocht an cábail a ardú ó 70°C go 90°C (ag briseadh an t-insil), ag spreagadh seanóis agus briseadh insil (mar shampla, XLPE).

Saol Gearr: Cuireann teaspachadh fadtéarmach saol an chábail ó 30 bliain go 15–20 bliain, ag déanamh "insil breakdown" agus deifecte scuitse. (D'imir an parc tionsclaíoch dhá 10kV cábail laistigh den bhliain mar gheall ar 3rd harmonic, ag costas níos mó ná 800,000 RMB sa chur chuige.)

1.2 Transformaitheoirí Cúrra (CTs)

Meicnísmí Damáiste: Cuireann na harmónaigh cúrra (go háirithe 3rd agus 5th) san "transient saturation" core CT, ag méadaú go mór hysteresis agus eddy current losses (additional iron losses). Briseann an saturation an fhoirmshaothar an taobh dara, ag cosaint a léiriú cruinn ar an gcúrra bunord.

Damáiste Speisific:

Core Overheating: D'fhéadfadh teocht an core CT a bheith níos mó ná 120°C, ag briseadh insil ar an bhfaisnéis dheireanach agus ag déanamh míchruinn ar an ratio.

Protection Misoperation: Léiríonn an cúrra deireanach diabháltacht "line short circuits," ag triopadh bréagach. (Fuair an líonra díol 10 feeder trips mar gheall ar sátracht CT, ag éifeachtaí 20,000 tithe.)

2. Táirgeadh Díol: Teipithe Forleathana, Téiteán Stábla Sistéime

Is tábhachtach an t-equipment díol do "connecting upstream and downstream" sa grid. Téann na harmónaigh roimh ré an damáiste is diabhálta. Is iad na príomhchuidiú a bhfuil tionchar orthu ná transformaitheoirí cumhacht, bancanna capacitor, agus reacaitheoirí.

2.1 Transformaitheoirí Cumhacht (Díol / Main Transformers)

Meicnísmí Damáiste: Méadaíonn na harmónaigh voltaige magnetic hysteresis agus eddy current losses sa core (additional iron losses); harmónaigh cúrra méadaíonn winding copper losses. In ainneoin sin, is minic a ardú ar an gcumhacht uile. Harmónaigh trí phhás neamhchothroime freisin méadaíonn neutral current (go dtí 1.5× phase current), ag éifeachtaí teaspachadh áitiúil.

Damáiste Speisific:

Core Overheating: Ag THDv = 8%, transformer iron losses increase by 15%-20%. Core temperature rises from 100°C to 120°C, accelerating degradation of insulating oil (e.g., 25# transformer oil), increasing acidity, and reducing dielectric strength.

Winding Burnout: Long-term overheating carbonizes winding insulation paper (e.g., Nomex), leading to short circuits. A substation's 110kV main transformer suffered a winding short after 3 years due to excessive 5th harmonic, with repair costs exceeding 5 million RMB.

Reduced Lifespan: Prolonged THD reduces transformer lifespan from 20 years to 10–12 years.

2.2 Shunt Capacitor Banks (for Reactive Power Compensation)

Damage Mechanism: Capacitive reactance decreases with frequency (Xc = 1/(2πfC)), so high-frequency harmonics induce overcurrent. If capacitors form "harmonic resonance" with grid inductance (e.g., 5th-order resonance), current can surge to 3–5× rated value—far beyond capacitor ratings.

Specific Damages:

Insulation Breakdown: Overcurrent heats internal dielectrics (e.g., polypropylene film), causing puncture, bulging, or even explosion. (An industrial workshop damaged three 10kV capacitor banks within one month due to 7th harmonic resonance; replacement cost per bank exceeded 150,000 RMB.)

Protection Failure: Resonant currents burn out fuse links; if protection fails to act, fire risk increases.

2.3 Series Reactors (for Harmonic Suppression)

Damage Mechanism: Although used to suppress specific harmonics (e.g., 3rd, 5th), reactors suffer increased winding copper losses under long-term harmonic current. Pulsating magnetic fields from harmonics also intensify core vibration, causing mechanical wear.

Specific Damages:

Winding Overheating: At THDi = 12%, reactor copper losses increase by over 30%; winding temperatures exceed 110°C, causing insulation varnish to carbonize and flake off.

Core Noise & Wear: Vibration frequency couples with harmonics, producing loud noise (>85 dB). Long-term vibration loosens silicon steel laminations, reducing permeability and rendering harmonic suppression ineffective.

3. Generation Equipment: Output Limitation, Rising Safety Risks

Generation equipment is the "energy source" of the grid. Excessive THD negatively impacts operational stability. Key affected devices: synchronous generators, renewable inverters (PV/wind).

3.1 Synchronous Generators (Thermal/Hydro Plants)

Damage Mechanism: Grid harmonics back-feed into generator stator windings, creating "harmonic electromagnetic torque." Superimposed on fundamental torque, this forms "pulsating torque," increasing vibration. Harmonic currents also raise stator copper losses, causing local overheating.

Specific Damages:

Reduced Output: A 300MW unit at THDv = 6% experiences ±0.5% speed fluctuation due to pulsating torque, reducing output below 280MW, decreasing efficiency by 5%-8%.

Winding Overheating: Stator temperature may reach 130°C (exceeding Class A insulation limit of 105°C), accelerating insulation aging and risking turn-to-turn short circuits.

Bearing Wear: Increased vibration accelerates bearing (e.g., sleeve bearing) wear, reducing lifespan from 5 years to 2–3 years.

3.2 Renewable Inverters (PV / Wind)

Damage Mechanism: Inverters are sensitive to grid THD (per GB/T 19964-2012). If point-of-interconnection THDv > 5%, the inverter triggers "harmonic protection" to avoid damage. Additionally, harmonic voltage causes power imbalance between DC and AC sides, leading to IGBT module overheating.

Specific Damages:

Grid Disconnection: At a wind farm with THDv = 7%, 20 units of 1.5MW inverters disconnected simultaneously, abandoning over 100,000 kWh of wind energy in one day, costing ~50,000 RMB in lost revenue.

IGBT Burnout: Long-term operation under harmonics increases switching losses in IGBT modules (core component), raising temperature above 150°C, risking "thermal breakdown." Repair cost per inverter exceeds 100,000 RMB.

4. Control Equipment: Sampling Distortion, System Malfunctions

Control equipment acts as the "brain and nervous system" of the grid. Excessive THD causes distorted sampling data and abnormal command transmission. Key affected devices: protective relays, automation communication systems.

4.1 Protective Relays (Overcurrent / Differential Protection)

Damage Mechanism: Harmonic currents cause transient CT saturation, distorting sampled current waveforms (e.g., flat-topped waves), leading protection algorithms to misjudge amplitude and phase, triggering incorrect actions. Harmonic voltages may also interfere with relay power supplies, causing logic circuit malfunctions.

Specific Damages:

False Tripping: A distribution network with THDi = 12% experienced distorted CT output due to saturation, causing overcurrent protection to falsely detect "line short circuit" and trip 10 feeders, cutting power to 20,000 households for 4 hours, resulting in indirect economic losses exceeding 2 million RMB.

Failure to Trip : If harmonic interference causes ±10% voltage fluctuation in the relay’s power supply, the logic circuit may crash, failing to trip during actual faults, allowing fault escalation.

4.2 Automation Communication Devices (RS485 / Fiber Modules)

Damage Mechanism: Electromagnetic radiation from harmonics (e.g., 10V/m RF interference) couples into communication lines, causing "bit flips" in data transmission. Harmonic voltages also disrupt clock modules, increasing synchronization errors.

Specific Damages:

Increased Bit Error Rate: Due to harmonic interference, RS485 communication bit error rate in a distribution automation system rose from 10⁻⁶ to 10⁻³, delaying or losing dispatch commands (e.g., "adjust capacitor switching").

Module Burnout: High-frequency harmonics can break down signal isolation circuits (e.g., optocouplers) in communication modules, causing failure. One substation destroyed 8 fiber modules within a month due to 5th harmonic interference.

5. End-Use Equipment: Performance Degradation, Production Accidents

End-use equipment represents the "terminal load" of the grid. Industrial and precision equipment suffer most severely from excessive THD. Key affected devices: industrial motors, precision equipment (lithography machines / medical MRI).

5.1 Industrial Motors (Induction / Synchronous Motors)

Damage Mechanism: Harmonic voltage generates "harmonic currents" in motor stator windings, forming "negative sequence rotating magnetic fields." When superimposed on the fundamental field, they produce "braking torque," causing speed fluctuations and increased vibration. Harmonic currents also increase stator/rotor copper losses, leading to overall overheating.

Specific Damages:

Efficiency Drop: A 100kW induction motor at THDv = 7% sees efficiency drop from 92% to below 85%, consuming over 50,000 kWh extra annually (at 0.6 yuan/kWh, additional electricity cost: 30,000 yuan/year).

Burnout: A steel plant’s rolling mill motor burned out twice within six months due to prolonged 7th harmonic exposure; stator temperature reached 140°C. Replacement cost per motor exceeded 2 million RMB.

Vibration & Noise: Motor vibration acceleration increased from 0.1g to 0.5g, noise exceeded 90dB, affecting working environment and accelerating foundation wear.

5.2 Precision Equipment (Semiconductor Lithography Machines / Medical MRI)

Summary: Core Rules of THD-Induced Equipment Damage

Inductive Equipment (Transformers, Motors, Reactors): Vulnerable to "Additional Losses" — harmonics increase iron/copper losses, with overheating and aging being primary damages.

Capacitive Equipment (Capacitors): Vulnerable to "Resonant Overcurrent" — harmonics easily trigger resonance, with overcurrent-induced insulation breakdown being the main damage.

Control Equipment (Relays, Communication Systems): Vulnerable to "Sampling Distortion" — harmonics distort data, leading to misoperations or failures to operate.

Precision Equipment (Lithography Machines, MRI): Vulnerable to "Waveform Distortion" — harmonics increase voltage ripple, leading to loss of accuracy.

Therefore, power grids must adopt a dual strategy:

"Harmonic Monitoring (controlling THD measurement error ≤ ±0.5%) + Active Filtering (APF) / Passive Filtering"

to keep THDv within the national standard limit of 5%, thereby preventing equipment damage at the source.